Environment-friendly facility for asphalt mixing plant

An asphalt mixing station and asphalt mixing technology, which is applied in the direction of road, dispersed particle separation, road repair, etc., can solve the problems of unpurified waste gas treatment, poor dust removal effect, etc., and achieve the effect of preventing water vapor backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

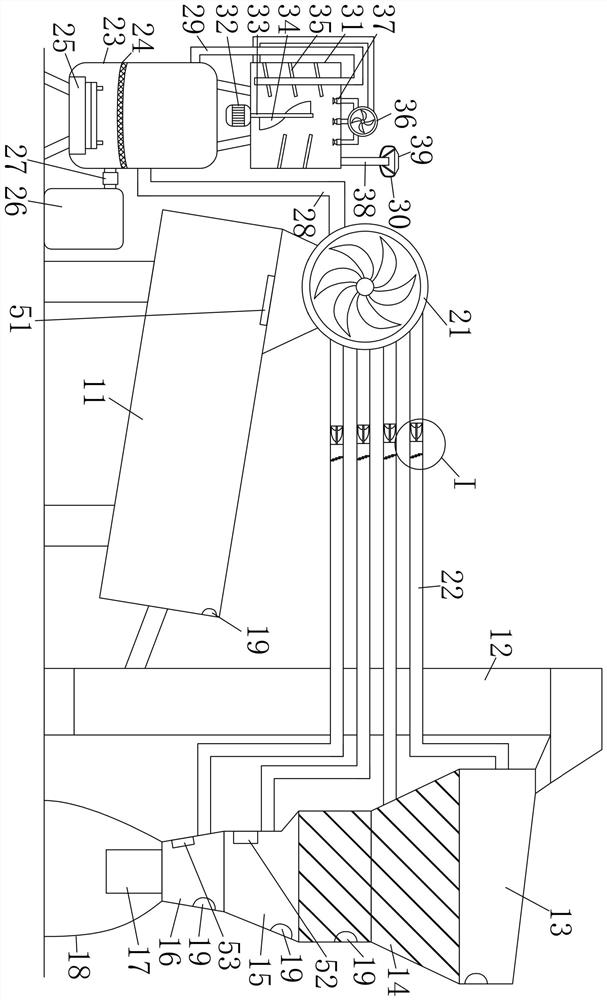

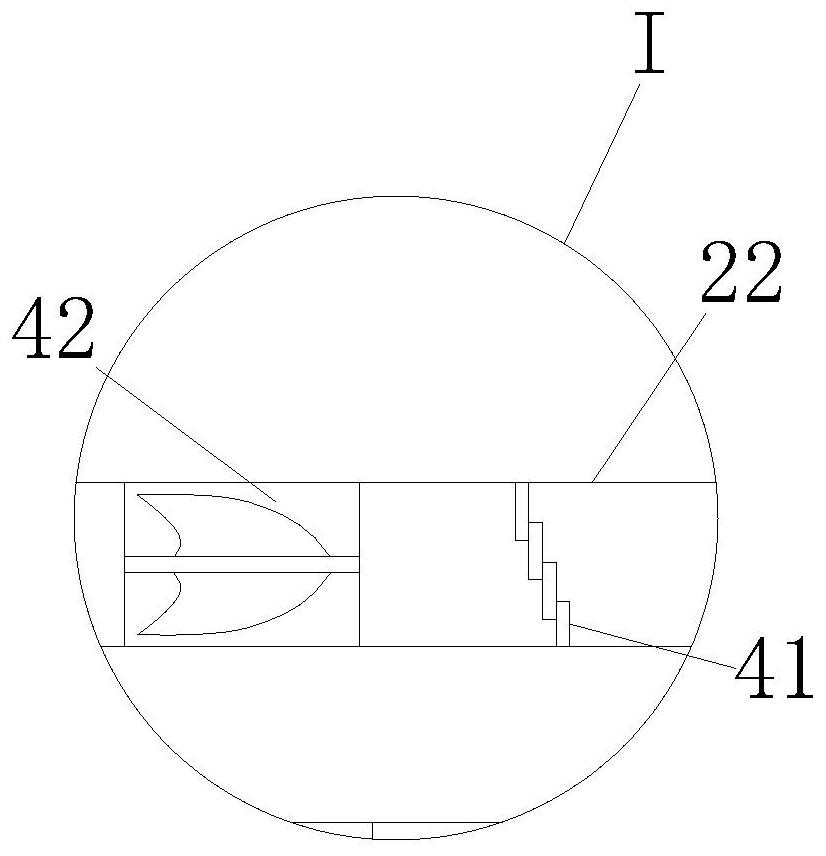

[0022] Such as Figure 1-2 As shown, an asphalt mixing plant environmental protection facility is provided in the embodiment, including an asphalt mixing device and a dust and smoke collection device. It is connected with the mixing building. The mixing building includes a screening bin 13, a storage bin 14, a metering bin 15 and a mixing tank 16 connected sequentially from top to bottom. The bottom of the mixing tank 16 is connected with a discharge port. The dust and smoke collection device includes a fan 21, more than two exhaust pipes 22, a combustion cylinder 23, a spray cylinder 31 and an output pipe 38. 22 is connected with the fan 21, the output end of the fan 21 is connected in the combustion cylinder 23 through the first transfer pipe 28, the top of the combustion cylinder 23 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com