Miniature electric hoist

An electric hoist and miniature technology, applied in the direction of hoisting device, portable hoisting device, etc., can solve the problems that the wire rope cannot be detected and avoided in time, cannot be monitored by the wire rope, and cannot be adjusted in speed, so as to reduce the risk of accidents and avoid The effect of disordered winding and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

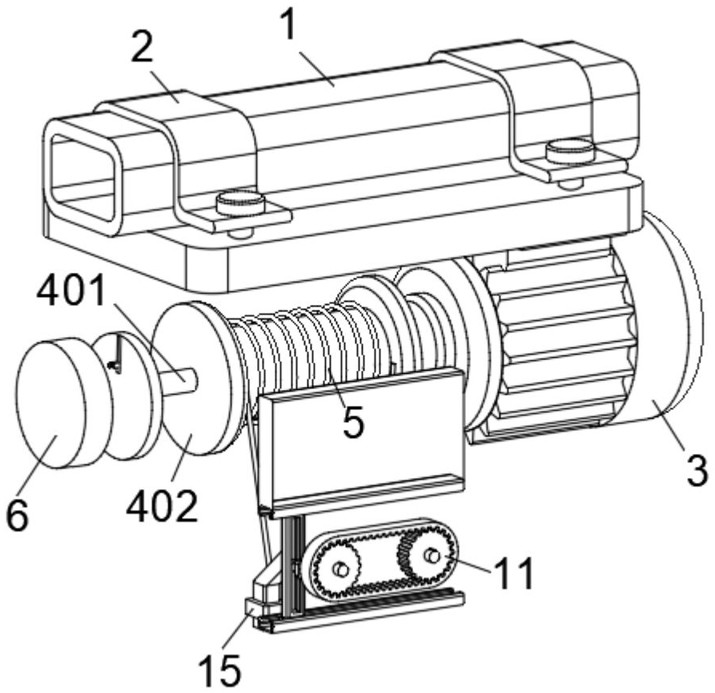

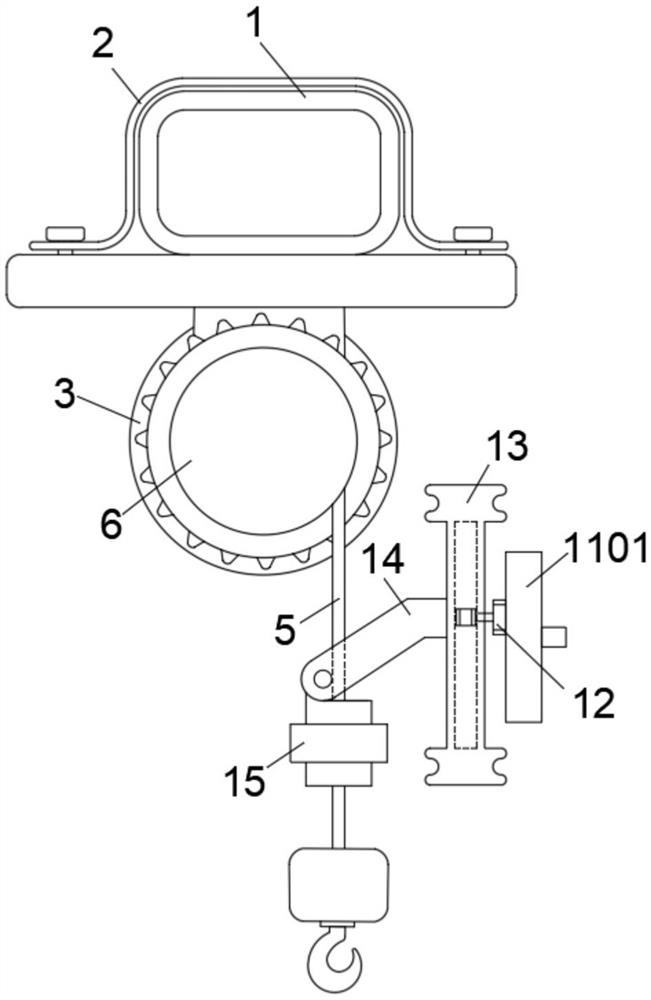

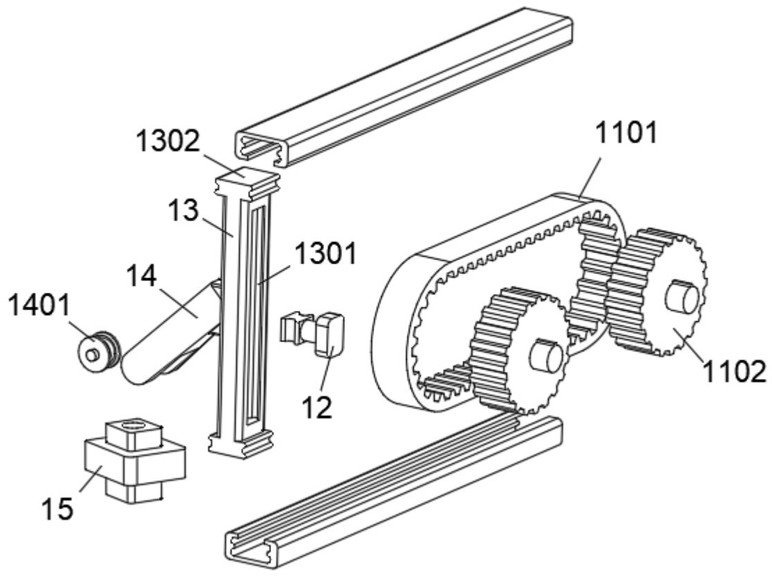

[0030] Embodiment: a miniature electric hoist, including a guide rail 1 for position adjustment, the guide rail 1 is fixedly connected with a mounting base through a connecting plate 2, the lower end of the mounting base is fixedly installed with a first motor 3, and the output shaft of the first motor 3 is installed There is a winding mechanism 4, the mounting seat is located on the left side of the winding mechanism 4, and an adjusting slowing mechanism 6 is provided. The output shaft of the first motor 3 is connected with a winding restraint mechanism 11 through a transmission mechanism 10, and the winding restraint mechanism 11 is An auxiliary detection mechanism 15 is also provided.

[0031] According to attached figure 1 As mentioned in the above, when the device is in use, through the fixed connection between the first motor 3 and the output shaft of the first motor 3 and the winding wheel 402, it can drive the winding wheel 402 to carry out the wire rope 5 The rewindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com