Foaming agent filling device for decontamination vehicle

A technology of filling device and foaming agent, which is applied in the directions of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., can solve the problems of low work efficiency, high labor intensity, inconvenient operation, etc. Short, safe and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the examples.

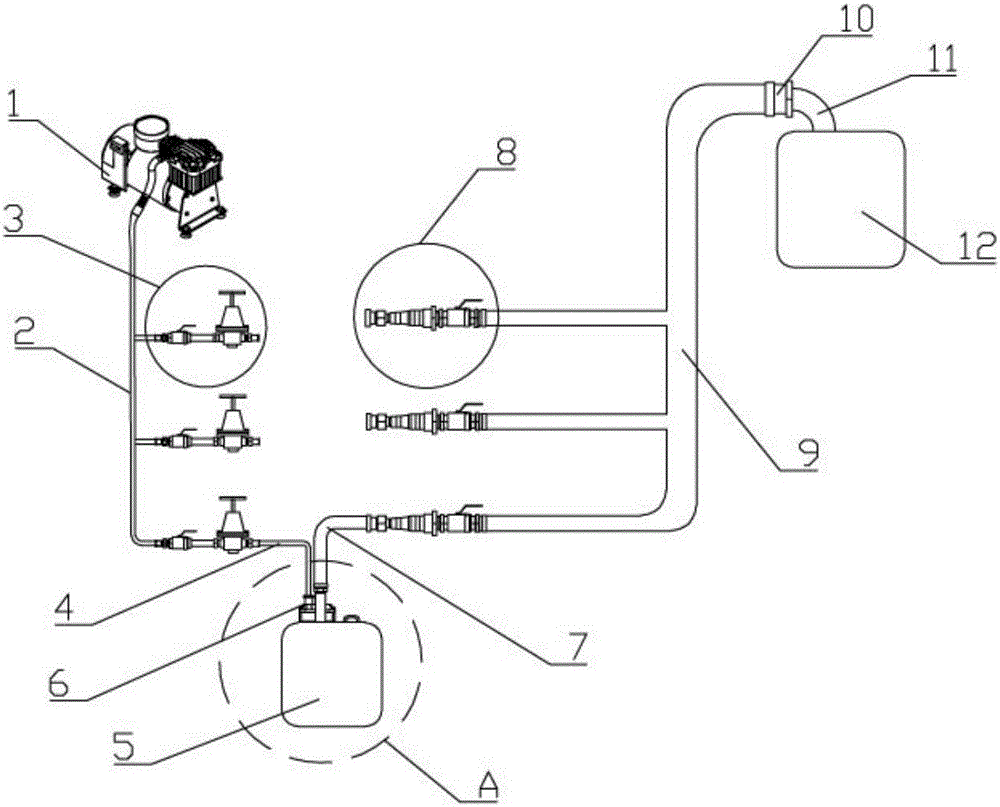

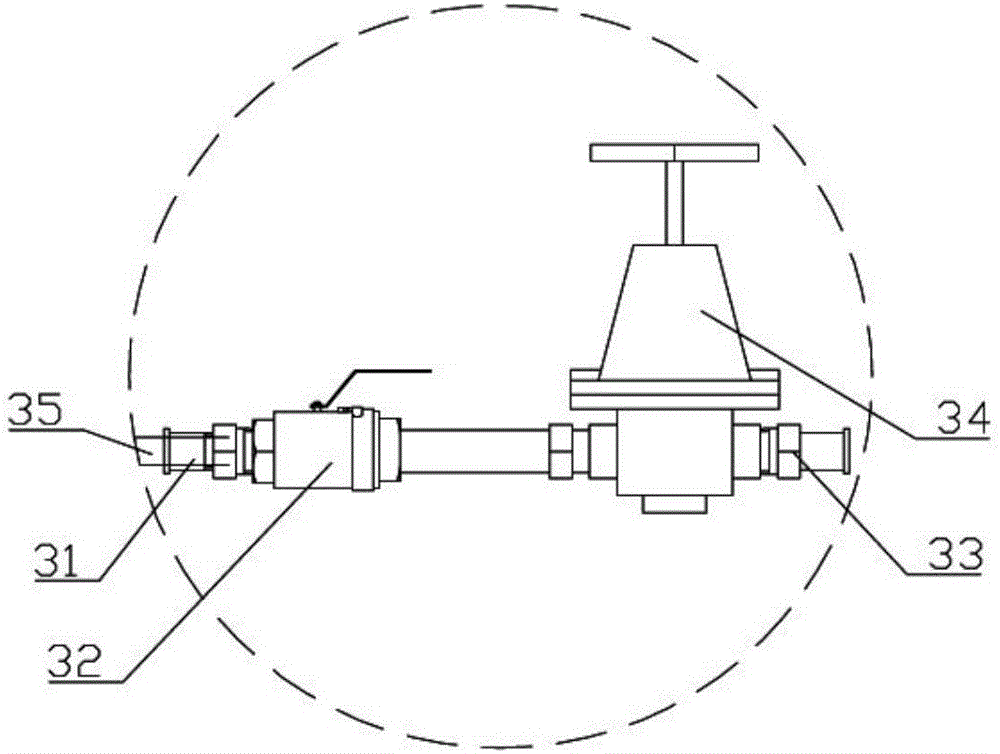

[0030] Such as figure 1 As shown, a foaming agent filling device for decontaminating vehicles of the present invention includes an air compressor 1, an air intake unit 3, a liquid filling cover 6 and a liquid outlet unit 8, and the outlet end of the air compressor 1 is connected with an air outlet main pipe 2 , the air outlet main pipe 2 is connected to the air intake unit 3, the outlet end of the air intake unit 3 is connected to the air intake pipe 4, the air intake pipe 4 is connected to the liquid filling cover 6, the liquid filling cover 6 is threadedly connected to the foam material barrel 5, and the upper end of the liquid filling cover 6 The liquid outlet pipe 7 is connected, the liquid outlet pipe 7 is connected with the liquid outlet unit 8, the outlet end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com