Automatic positioning machining operation table for aluminum edge framing profile

A technology of automatic positioning and operating table, which is applied in the field of aluminum frame profiles, to achieve the effect of simple operation, novel design and easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

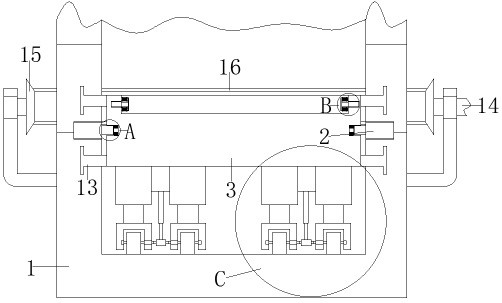

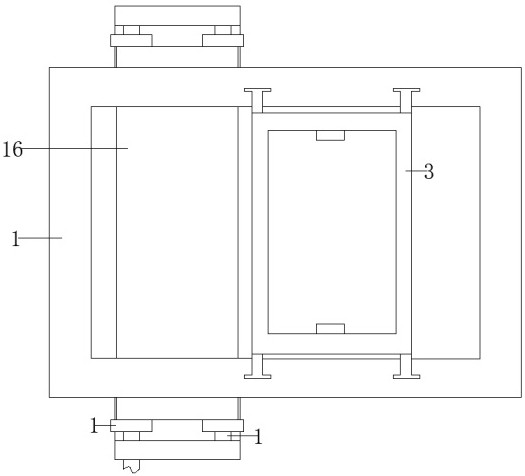

[0024] Refer Figure 1-6 One embodiment of this plan: An automated positioning processing operator for aluminum side frame, including operating tables 1, and an internal sleeve of the operating table 1 is provided with a fixed mechanism, and the fixing mechanism is provided with one side close to each other. On the top of the board 3, the positioning mechanism is connected inside the top of the operation plate 3, and a plurality of moving elevator mechanisms are connected in the bottom of the operation plate 3, and a conveying mechanism is provided behind the operation panel 3.

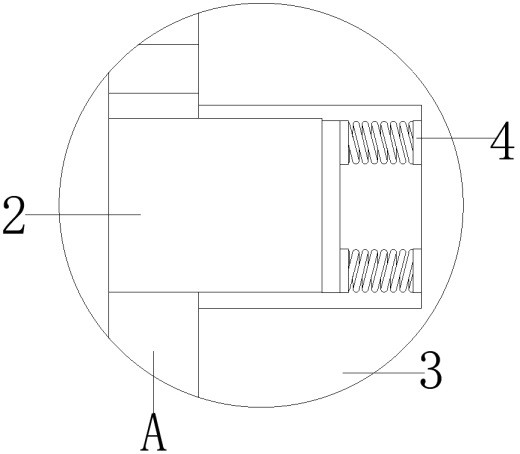

[0025] In the present embodiment, the fixing mechanism includes a plurality of pusher motor one 2, and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com