Automatic sand blowing device

A technology of sand blowing device and driving device, which is applied to casting molding equipment, casting molds, cores, etc., which can solve the problems of heavy labor workload, affecting the development of 3D printing casting industry, and high dust content, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings.

[0021] In the present invention, unless otherwise specified and limited, the terms should be understood in a broad sense, and those skilled in the art can understand the specific meanings of the terms in the present invention according to specific situations.

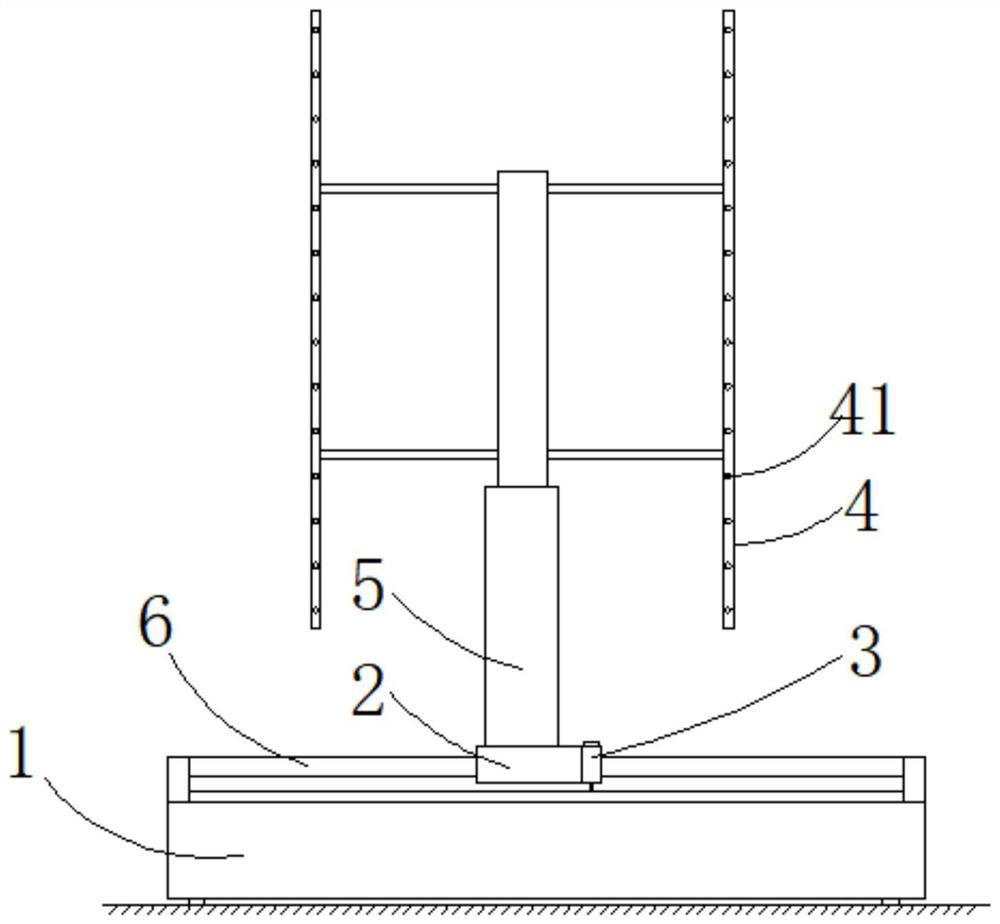

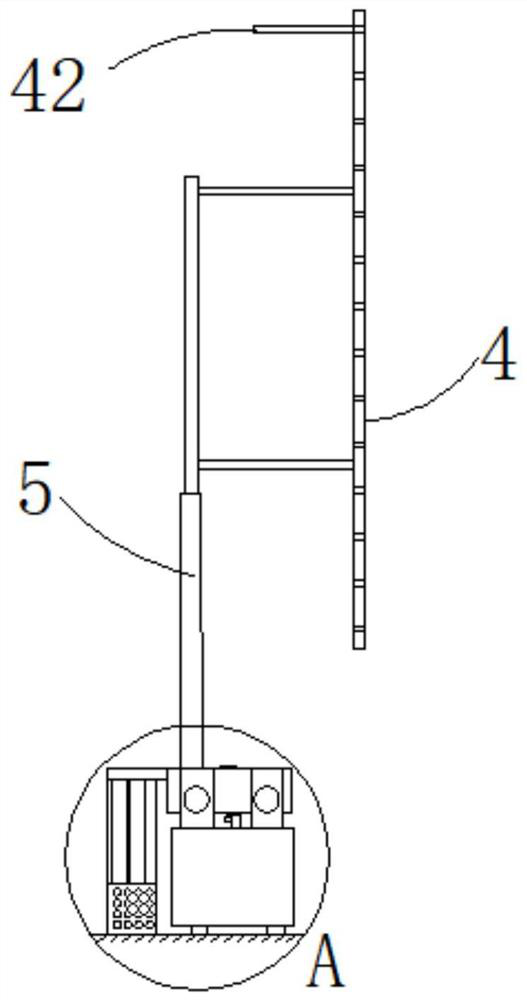

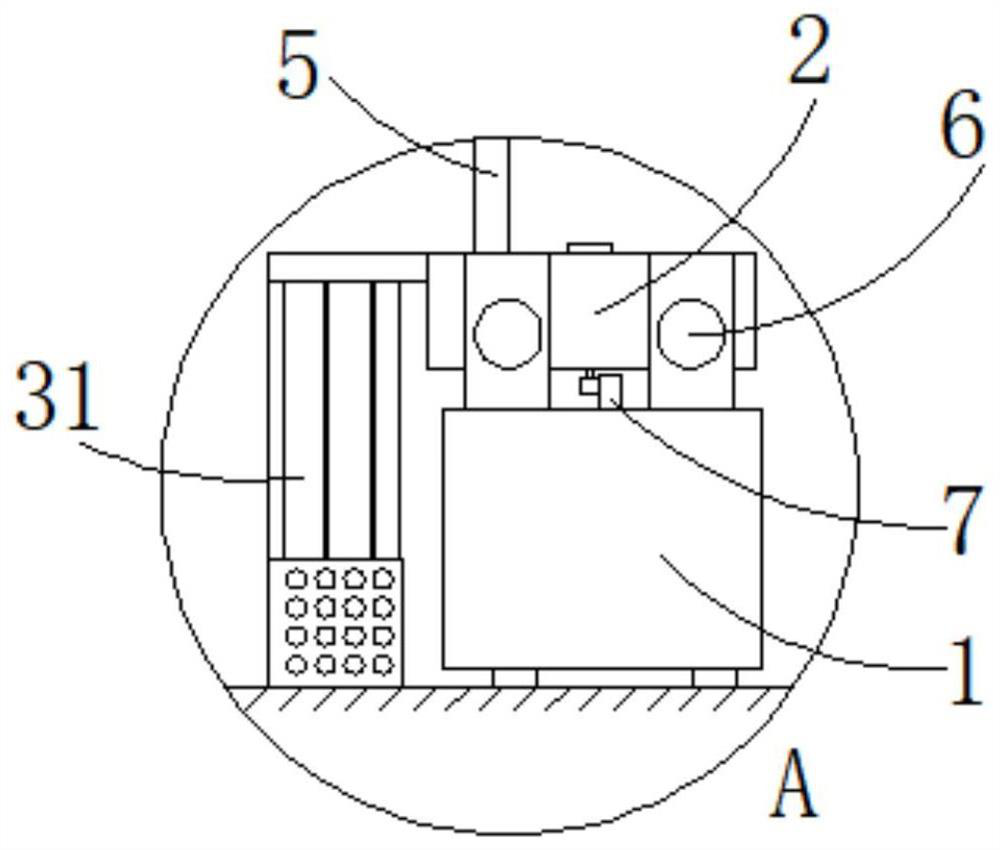

[0022] The invention provides an automatic sand blowing device, which includes a fixed frame, a moving part, a driving device, a telescopic rod and an air knife, the driving device is detachably installed on the moving part, and the driving device drives the moving part to reciprocating movement on the fixed frame; the telescopic rod includes a fixed rod and a movable rod, the fixed rod and the movable rod can move relatively, the fixed rod is vertically installed on the moving part, and the movable rod The rod is fixedly connected with the air kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com