A testing machine and testing method for semi-finished products of bridge piles

A technology of semi-finished products and testing machines, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc. It can solve the problems that unqualified products cannot be reused, silica gel cannot be reused, and the production efficiency of bridge stacks is low. High efficiency, saving working time and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

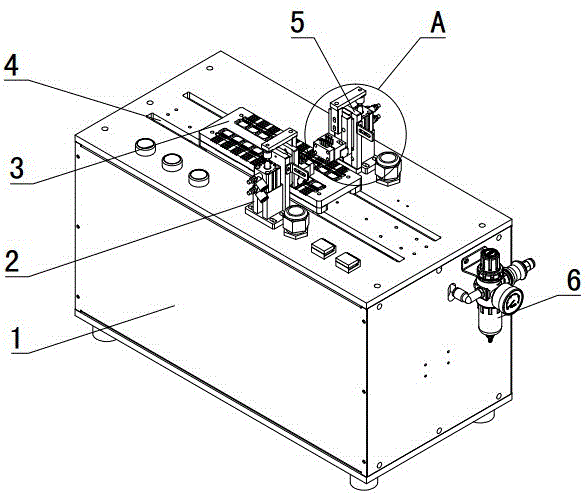

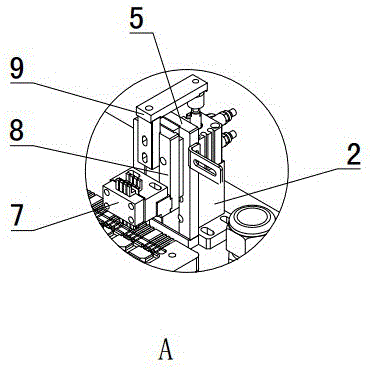

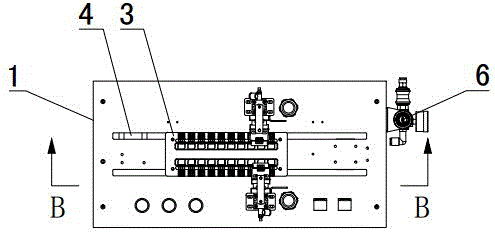

[0052] Such as figure 1 As shown: the bridge stack semi-finished product testing machine includes a frame 1, a test bench 3 arranged on the upper part of the frame 1, a test mechanism above the frame 1, a power mechanism in the frame 1, a test bench 3 and a Between the position detection mechanism and the control device. The bridge pile semi-finished products to be tested are neatly placed on the test platform 3, the power mechanism pushes the test platform 3 to reciprocate and transports the bridge pile semi-finished products, and the two testing agencies respectively test the bridge pile semi-finished products on both sides of the test platform 3, and the position detection mechanism can detect The position of the half-finished bridge stack, and upload the position signal of the semi-finished bridge stack to the control device; the control device controls the power mechanism to cooperate with the testing mechanism according to the signal detected by the position detection me...

Embodiment 2

[0080] The difference between embodiment 2 and embodiment 1 is that: the test bench 3 is only provided with a row of storage slots and insulation slots for placing semi-finished bridge stacks, and there is only one testing mechanism.

Embodiment 3

[0082] The difference between Embodiment 3 and Embodiment 1 is that the output shaft of the servo motor 18 is connected with a lead screw through a shaft coupling, the test bench mounting seat 10 is provided with a nut that is compatible with the lead screw, and the servo motor 18 is connected to the lead screw through the lead screw nut. The auxiliary pushes the test bench to move, so the structure is simple and it is not easy to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com