Steel-concrete-ultrahigh performance concrete combined segment and construction method thereof

An ultra-high-performance concrete technology, which is applied in the construction of highway tunnels and subways, can solve the problems of difficult maintenance and repair of underground structures, low material utilization efficiency, and large cross-sectional size, etc., and achieve uniform and compact microstructure, superior impermeability and Anti-corrosion ability and the effect of slowing down the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

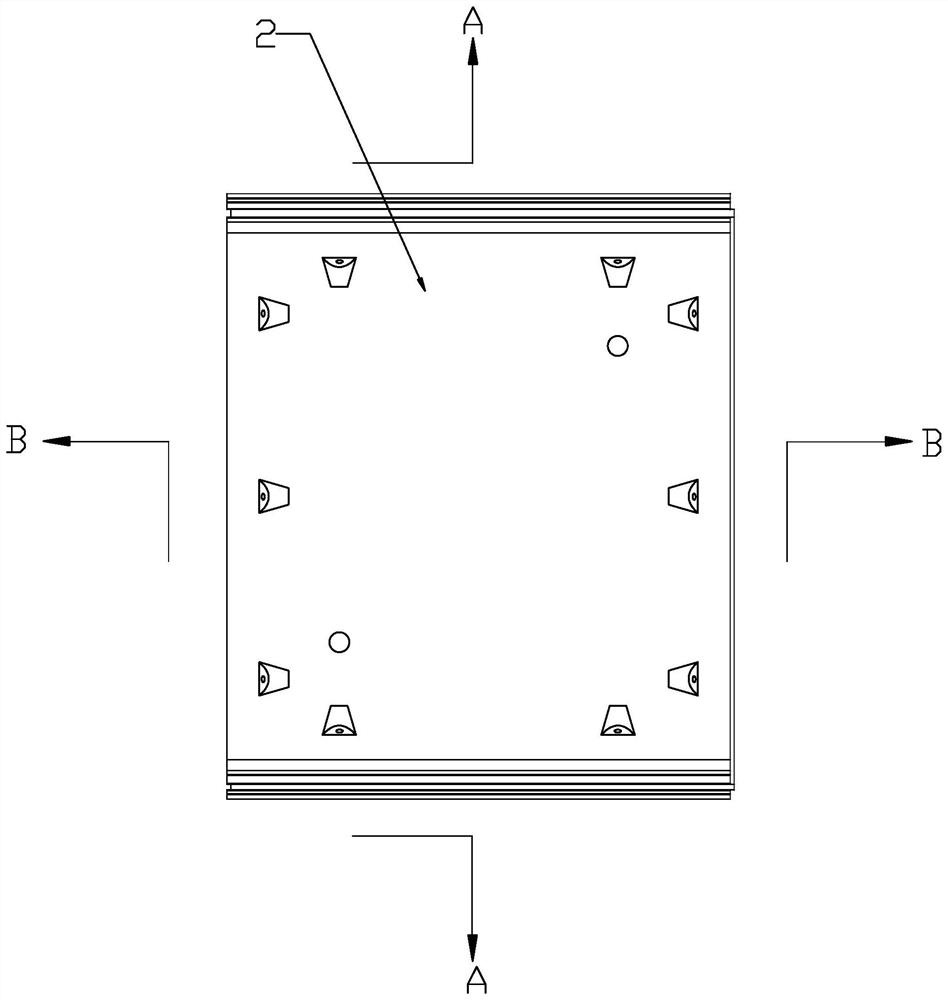

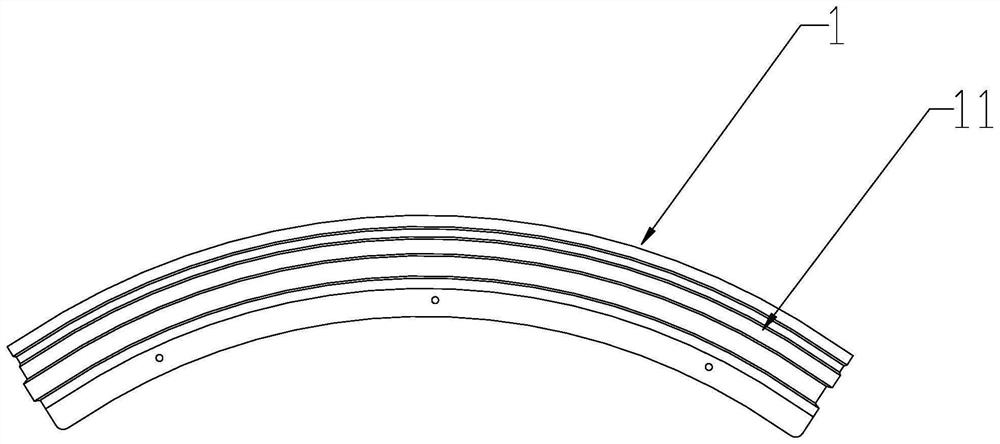

[0076] Such as Figure 1-3 As shown in and 4, a steel-concrete-ultra-high-performance concrete composite segment includes an upper ultra-high-performance concrete slab 1, a lower steel plate 2, and multiple pieces are placed between the upper ultra-high-performance concrete slab 1 and the lower steel plate 2 The connecting section steel 3 arranged along the circumferential direction of the lower steel plate 2, such as Figure 6 and 7 As shown, the upper ultra-high performance concrete slab 1 and the lower steel plate 2 are set in the same direction, the upper ultra-high performance concrete slab 1 and the lower steel plate 2 are connected by the connecting steel 3, and the upper ultra-high performance concrete A cavity 5 for filling concrete is formed between the high performance concrete slab 1 and the lower steel plate 2 .

[0077] Such as Figure 4 and 5 As shown, the connecting section steel 3 includes side section steel 33 arranged on both sides of the lower steel pla...

Embodiment 2

[0094] This embodiment only describes the differences from the above embodiments. In this embodiment, a reinforcement cage or a reinforcement mesh can also be arranged in the cavity 5 . When there is a higher demand for the bearing capacity of the segment, a reinforcement cage or a steel mesh can be arranged in the closed cavity 5 to further increase the bearing capacity of the segment.

Embodiment 3

[0096] This embodiment only describes the differences from the above-mentioned embodiments. In this embodiment, the lower steel plate 2 and the connecting steel 3 are connected by bolts, and by setting bolts on the lower end surface of the connecting steel 3 The holes are connected through the lower steel plate 2 and the connecting section steel 3 in turn through the pegs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com