A kind of unidirectional bending drilling tool and punching method for hole making and coal removal

A bending and one-way technology, which is applied in the field of one-way bending drilling tools and punching holes to create holes, can solve the problems of small range of water conservancy injection and limited range of single-hole pressure relief, and achieve the purpose of increasing the range of single-hole pressure relief, The effect of reducing engineering quantity and increasing coal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

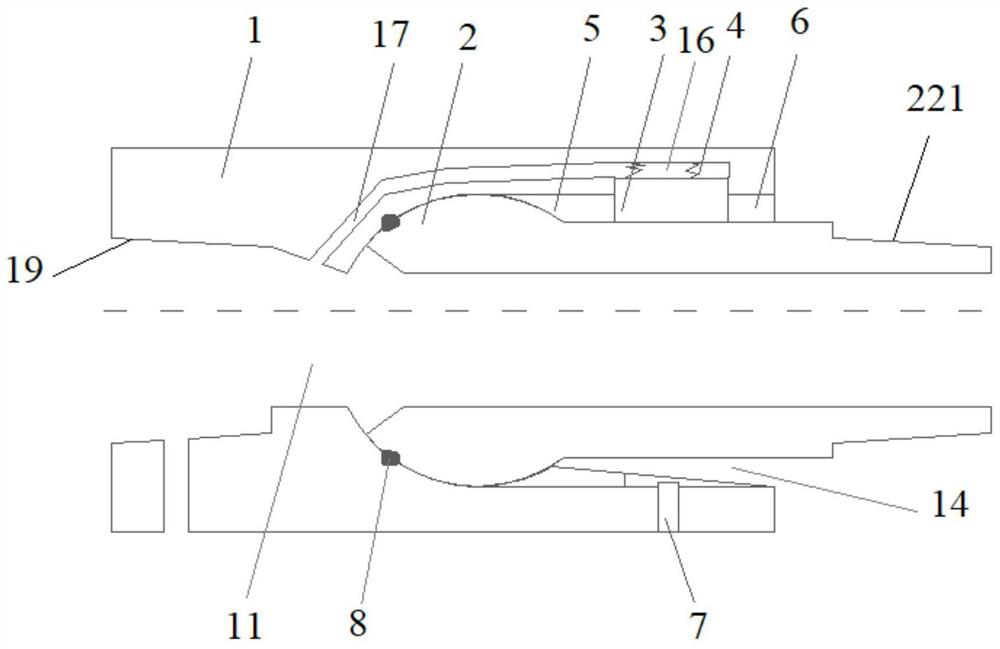

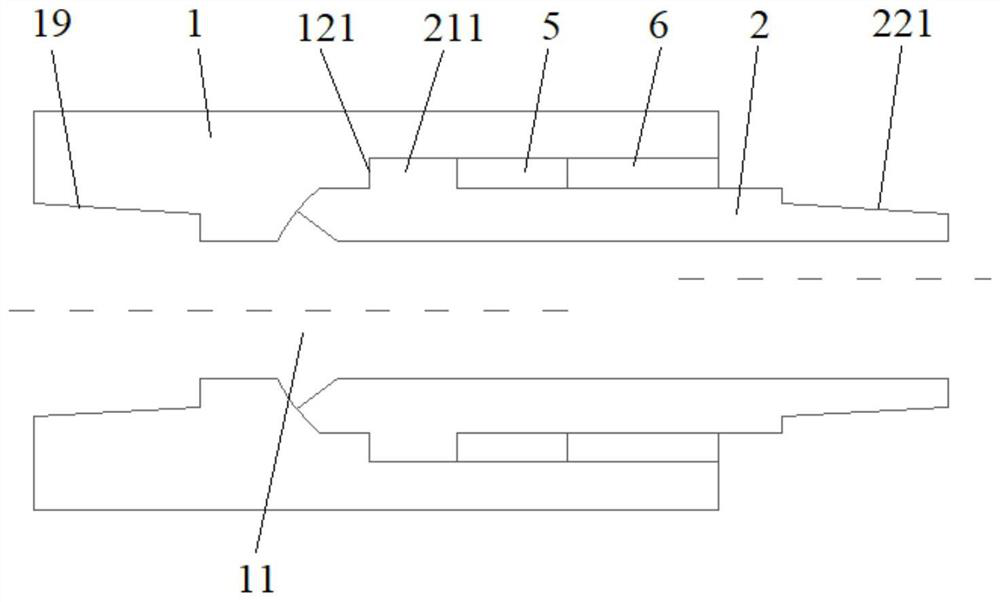

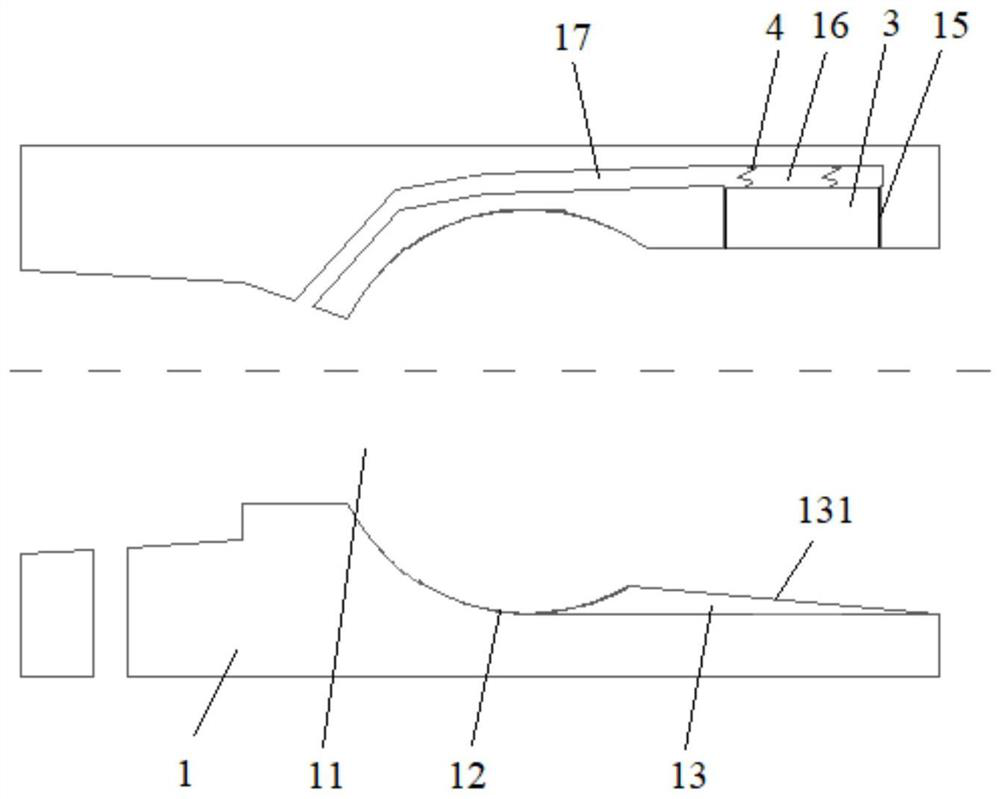

[0050] The present embodiment discloses a one-way curved drilling tool, which is formed by connecting a plurality of short sections in sequence. like figure 1 As shown, each short joint at least includes a seat section 1, a movable member 2, a push block 3 and an elastic member 4. The seat section 1 is provided with a central channel 11 for liquid flow, as a pressure injection channel, the movable member 2, the push block 3 and the elastic member 4 are arranged in the central channel 11 .

[0051] The movable part 2 is an annular part as a whole, and the channel 23 in the annular part is used for the injection liquid to pass through. Figure 10 shown.

[0052] The inner wall of the seat section 1 includes a spherical groove section 12 and a variable section section 13, such as image 3 As shown, the spherical groove section 12 matches the spherical surface of the movable ball head section 21; the variable section section 13 includes an equal section section and an inclined...

Embodiment 2

[0065] The present embodiment provides a method for punching and digging coal. The method uses the one-way curved drilling tool described in Embodiment 1 to punch and dig coal along the main hole direction. The process is as follows: Figure 14 shown, including the following steps:

[0066] Step 1, constructing the main hole 9. In this embodiment, conventional drilling tools (such as rock drilling tools, etc.) are used to drill to form the main hole 9. After seeing the coal seam 10, the drilling tool is proposed; The one-way bending drill tool of Example 1;

[0067] Step 2, when the head of the one-way bending drilling tool contacts the bottom of the main hole, start the mud pump to inject pressure into the central channel 11, and push the block 3 to apply a thrust to the movable part 2 under the action of hydraulic force, and the movable part 2 pushes toward a Lateral bending, and finally the whole one-way bending drilling tool is one-way bending, and then applying WOB, the ...

Embodiment 3

[0070] The extraction area given in this example is 12m×12m, the rock hole section is 50m, and the coal thickness is 3m. Taking domestic conventional cross-layer hole extraction as an example, the hole spacing is 3m × 3m, 16 holes need to be arranged, the total footage of rock hole section is 800m, and the footage of coal hole section is 48m. By adopting the invention to carry out 8 branches of punching and digging coal in each through-layer hole, only 4 holes are required, the total footage of the rock hole section is 200m, and the total footage of the coal hole section is 144m, which greatly reduces the amount of engineering and saves drilling tools. , which reduces the difficulty of work. The engineering quantity analysis of the two schemes is shown in Table 1.

[0071] Table 1 The present invention and conventional technology engineering quantity comparison table

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com