Novel thermoelectric chemical oxidation equipment and control method

A thermoelectrochemical and equipment technology, applied in the field of new thermoelectrochemical oxidation equipment and control, can solve the problems of large cooling power consumption, large electrical energy consumption, large energy consumption, etc. high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

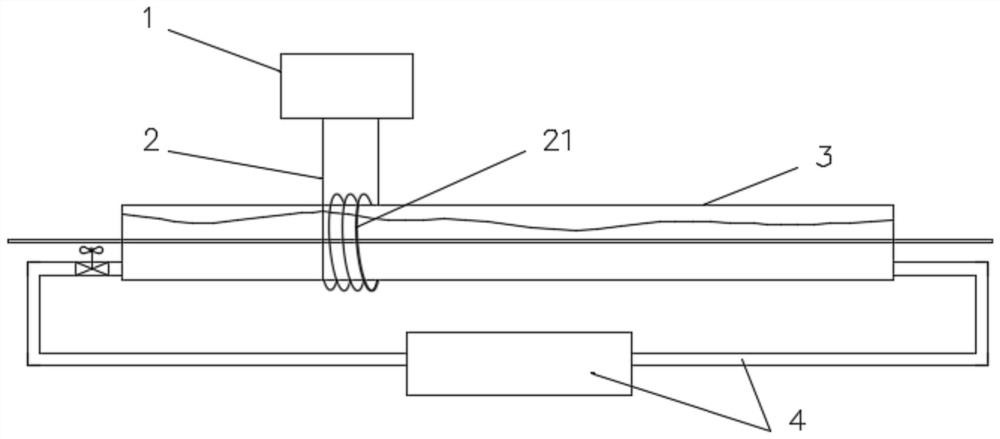

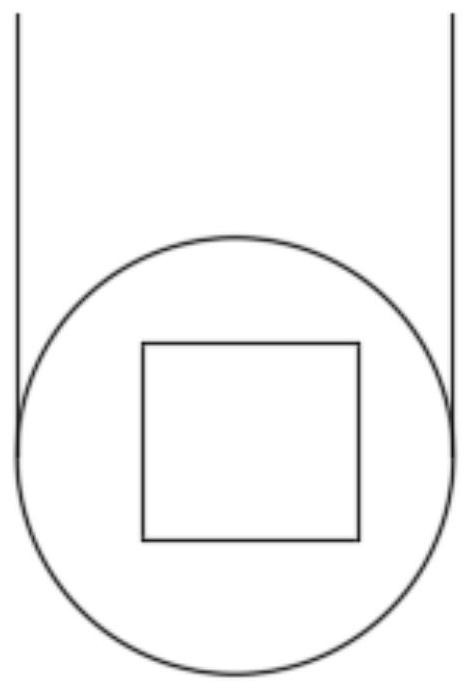

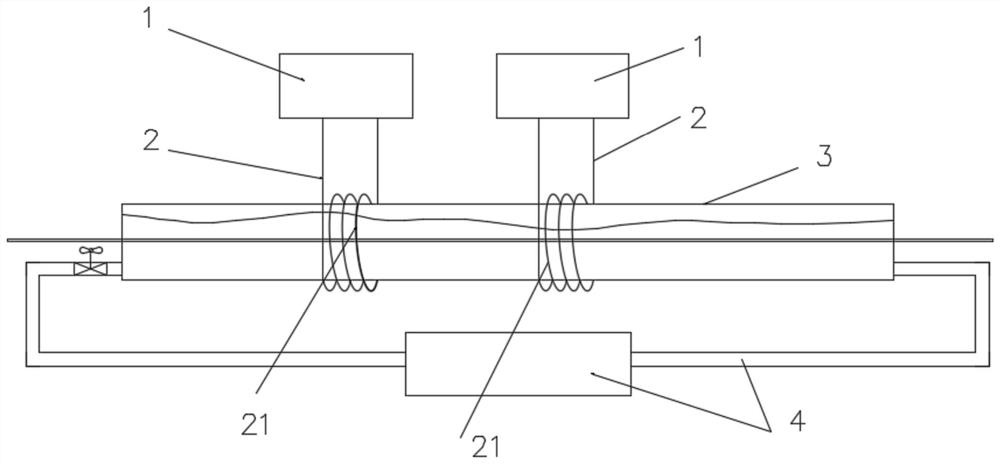

[0060] A device for thermoelectrochemical oxidation, such as Figure 1-Figure 2 As shown, it includes a high-frequency power supply 1, an induction coil part 2, an electrolyte pool 3, and a cooling system 4. The high-frequency power supply 1 is connected to the induction coil part 2, and the electrolyte pool 3 is connected to the cooling system 4. The electrolyte The pool 3 is used to contain the electrolyte, and the electrolyte in the electrolyte pool 3 circulates and flows into the cooling system 4 to cool down the electrolyte. The induction coil part 2 is formed by winding a multi-turn induction coil 21 outside the outer wall of the electrolyte pool 3. , and there is a gap between the induction coil 21 and the outer wall of the electrolyte pool 3, therefore, the height and width of the induction coil part 2 are greater than the height and width of the outer wall of the electrolyte pool 3, and the length of the induction coil part 2 is shorter than the electrolytic solution ...

Embodiment 2

[0069] A method for thermoelectrochemical oxidation, comprising: winding a multi-turn induction coil 21 outside the outer wall of the electrolyte pool 3 to form a circle, and maintaining a gap between the induction coil 21 and the outer wall of the electrolyte pool 3 to form an induction coil part 2. The length of the induction coil part 2 is less than the length of the outer wall of the electrolyte pool 3, and the two ends of the induction coil 21 are connected to the high-frequency power supply 1; the workpiece is immersed in the electrolyte in the electrolytic pool 3, and the workpiece passes through the induction coil part 2 At this time, the high-frequency voltage on the induction coil 21 generates a high-frequency current on the workpiece, and the high-frequency current concentrates on the surface of the workpiece to quickly generate high temperature on the surface of the workpiece. Under the joint action of high temperature, current and electrolyte, thermoelectrochemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com