Heat-treatment-free NM360 wear-resistant steel plate and manufacturing method thereof

A wear-resistant steel plate, heat-free technology, applied in the direction of temperature control, etc., can solve the problems of limited cold forming performance, long production process, different production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

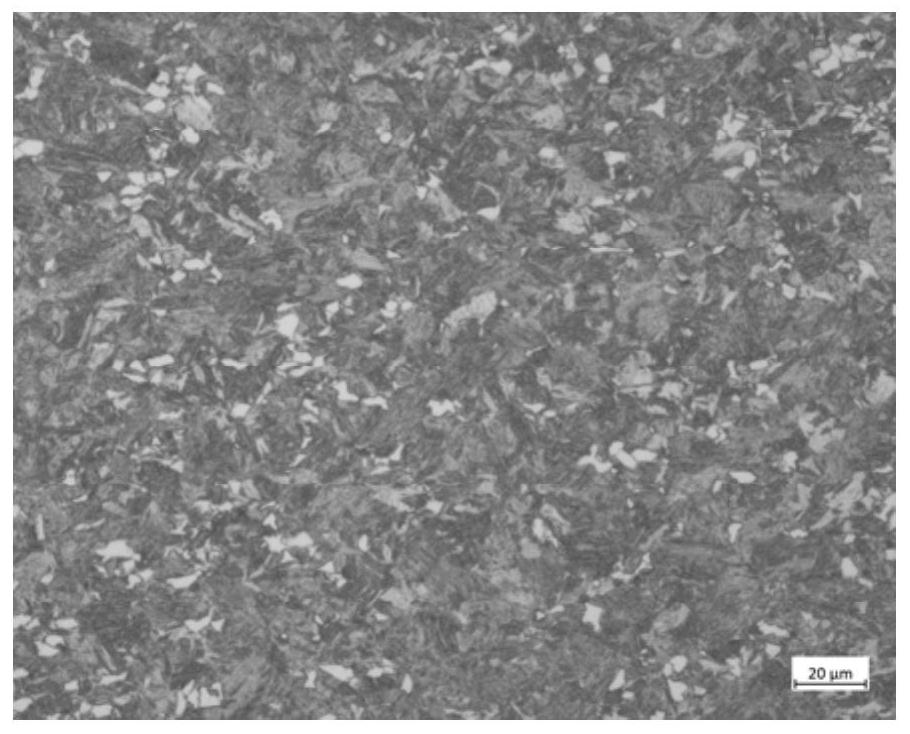

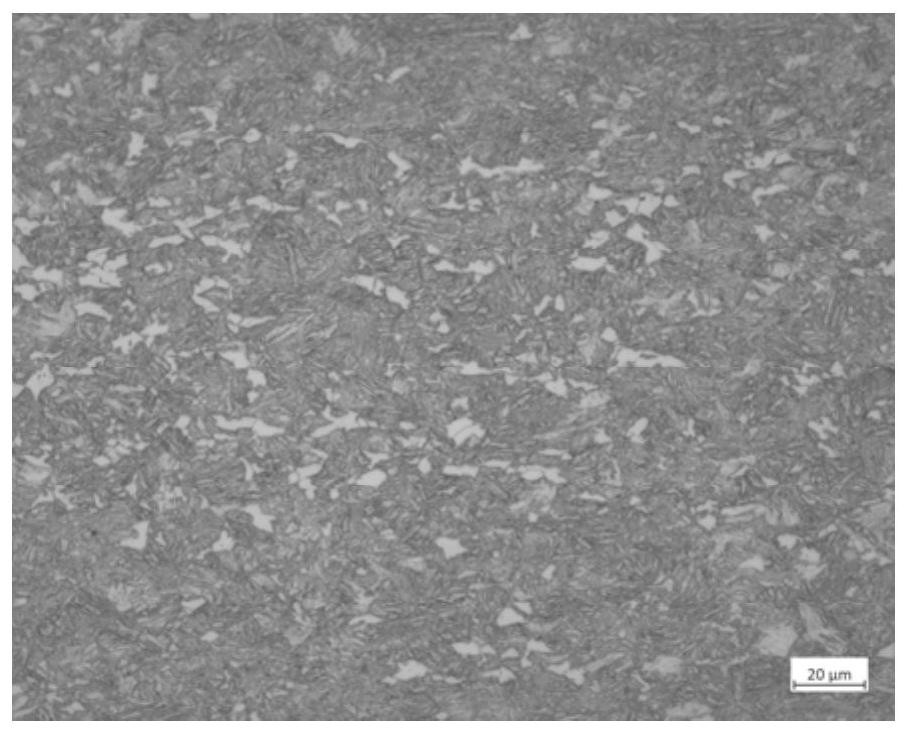

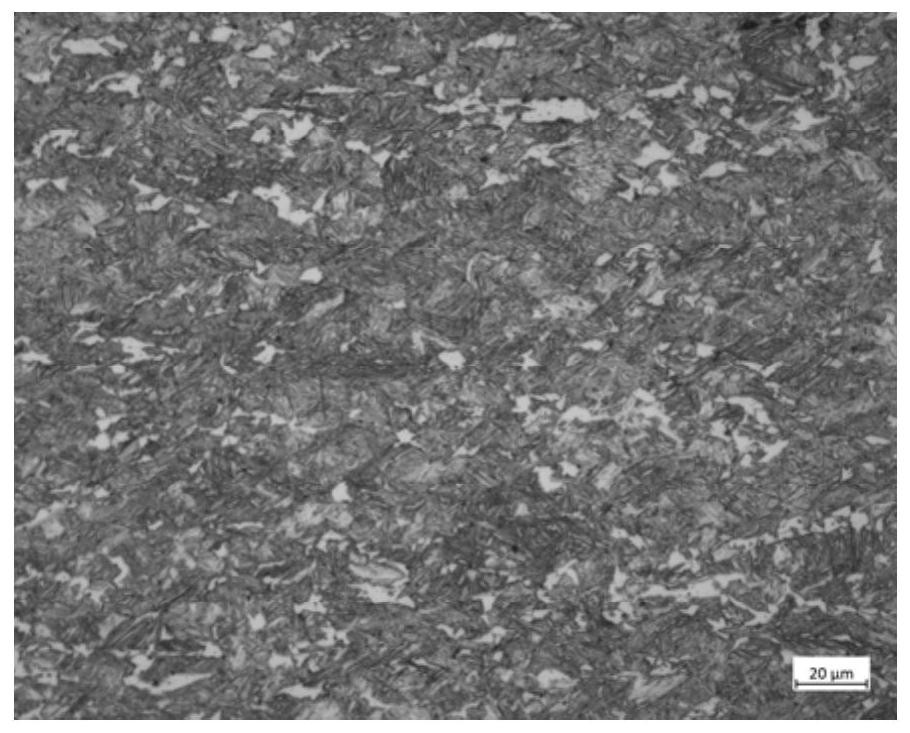

Image

Examples

Embodiment 1- Embodiment 4, comparative example 1- comparative example 2

[0046] A heat-free NM360 wear-resistant steel plate, its chemical composition is shown in Table 1, and the balance not shown in Table 1 is Fe and unavoidable impurities.

[0047] The measured chemical composition (mass percentage, wt %) of each embodiment of table 1, comparative example

[0048] serial number C Si mn P S Nb Ti V als B H O N Example 1 0.15 1.23 1.75 0.010 0.004 0.056 0.021 0.012 0.039 0.0011 0.00012 0.0019 0.0024 Example 2 0.16 1.63 1.68 0.008 0.005 0.015 0.058 0.025 0.053 0.0013 0.00014 0.0016 0.0019 Example 3 0.17 1.85 1.72 0.007 0.006 0.035 0.031 0.033 0.045 0.0016 0.00013 0.0010 0.0027 Example 4 0.22 2.31 2.23 0.009 0.005 0.026 0.035 0.050 0.030 0.0021 0.00012 0.0018 0.0022 Comparative example 1 0.17 1.60 1.80 0.010 0.005 0.034 0.036 0.038 0.041 0.0015 0.00013 0.0011 0.0028 Comparative example 2 0.12 1.20 1.25 0.011 0.003 0.036 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com