Hot-rolled steel material for automobile friction plate and preparation method thereof

A friction plate and steel technology, which is applied in the field of hot-rolled strip steel manufacturing, can solve the problems of large drop in hardness, unevenness, and easy cracking of products, and achieve the effect of improving the yield, service performance, and good cold forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in detail below in conjunction with the examples, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

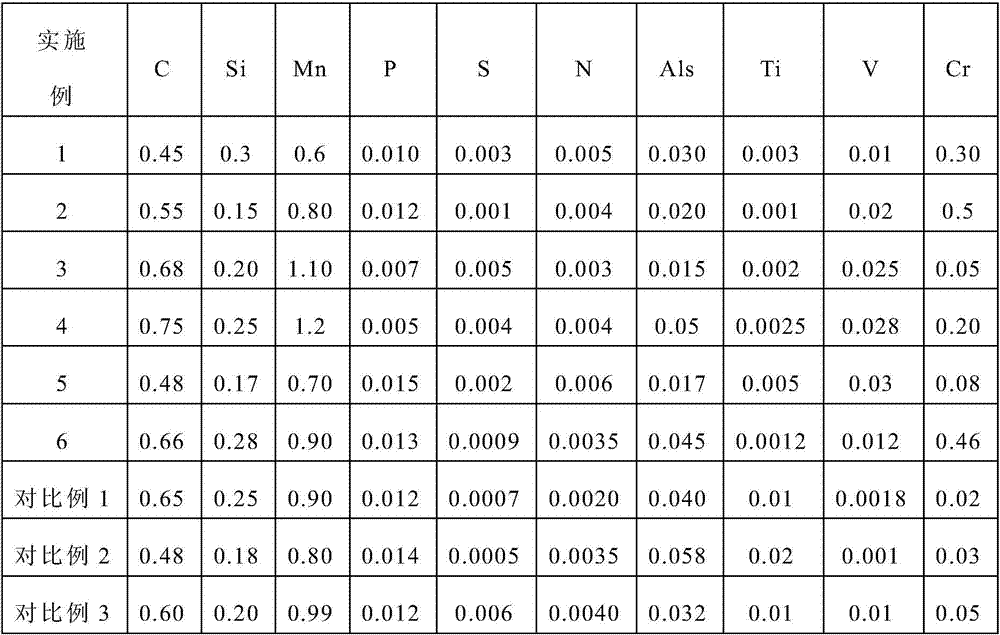

[0040] Table 1 shows the chemical composition and weight percentage of the hot-rolled steel for automobile friction plates in Examples 1-6, the chemical composition and weight percentage of the comparison steel for Comparative Examples 1-3, and the rest are Fe and unavoidable impurities.

[0041] Table 1 Chemical composition and percentage by weight (wt %) of each embodiment of the present invention and comparative example

[0042]

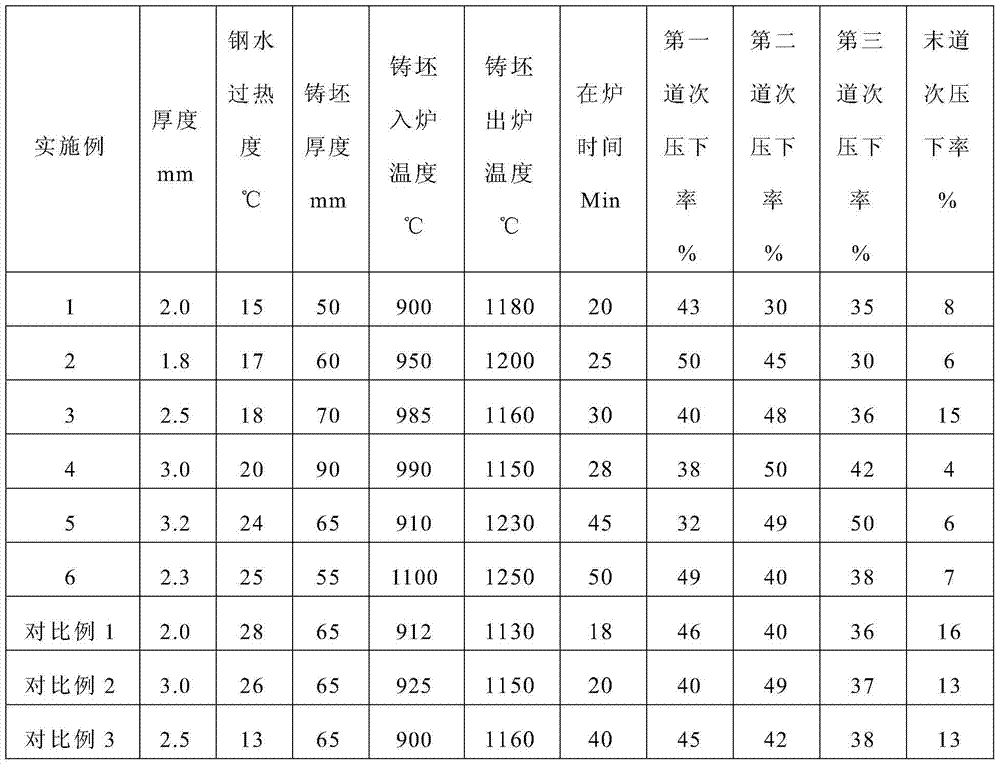

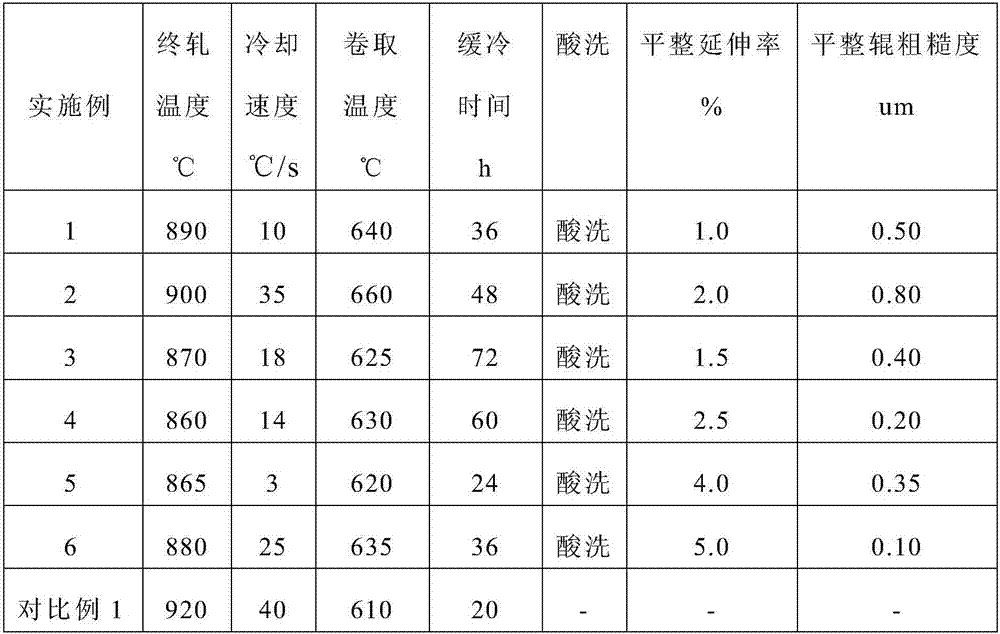

[0043]The hot-rolled steel material of the automobile friction plate is obtained by heating, controlled rolling, controlled cooling, coiling, slow cooling, pickling and smoothing the slab obtained after the chemical composition is smelt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com