Method and system for continuously preparing nano barium sulfate

A nano-barium sulfate and preparation system technology, which is applied in a field of continuous preparation of nano-barium sulfate, can solve the problems of difficult industrial production and residence, and achieve the effects of easy scale-up production, short residence time and high solution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

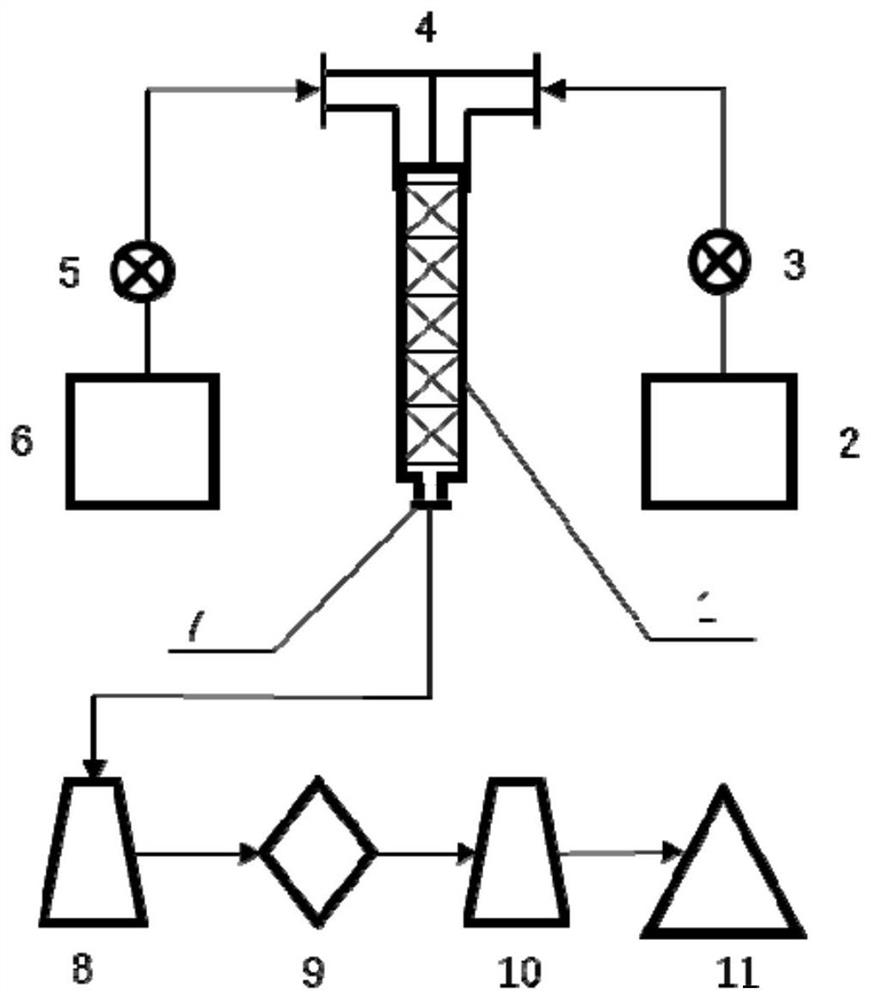

Method used

Image

Examples

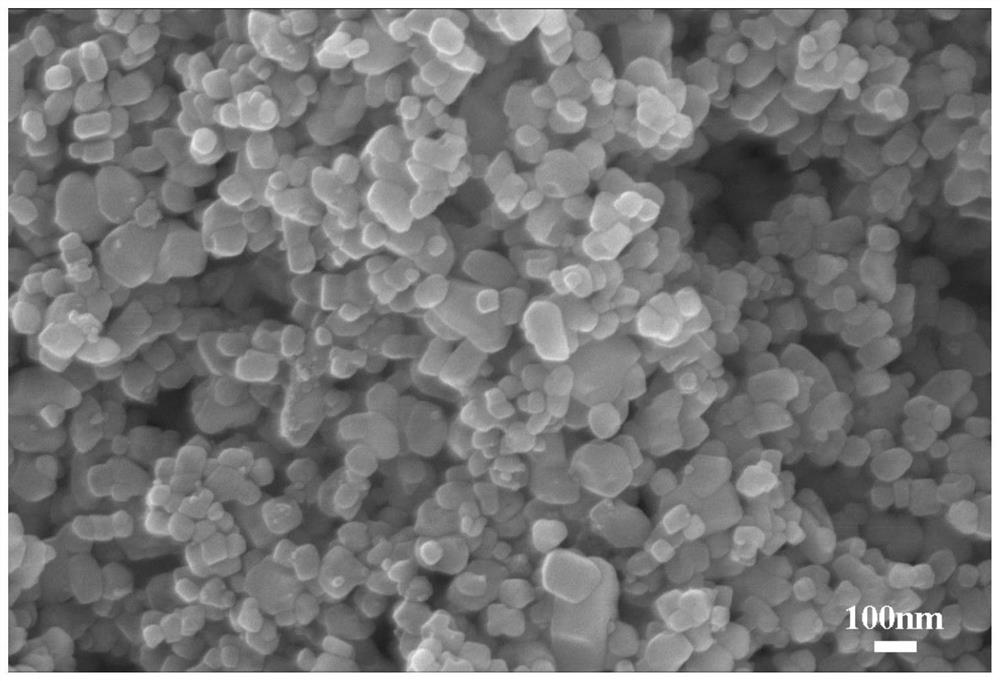

Embodiment 1

[0039] Industrial grade BaS was selected as the raw material of water-soluble barium compound, and a BaS solution with a concentration of 1 mol / L was prepared in a barium liquid storage tank at 60 °C. Select industrial grade Na 2 SO 4 As a raw material for sulfate, prepare Na at a concentration of 2.0 mol / L in a sulfate storage tank at 40°C 2 SO 4 solution. The inner diameter of the static pipeline mixing reactor is 5mm, and there are 5 SMV type mixing units inside. Two kinds of solutions are input in the pipe mixing reactor through the feed port, and the flow velocity of the BaS solution is controlled by the barium liquid feeding device 3 and the sulfate feeding device 5 to be 0.2m / s, Na 2 SO 4 The flow velocity of the solution is 0.1m / s, at this flow velocity, [Ba 2+ ]:[SO 4 2- ] The molar ratio (molar ratio) of the substances is 1:1.

[0040] The barium sulfate suspension obtained by the reaction is input into the first filter device, the soluble matter in the slur...

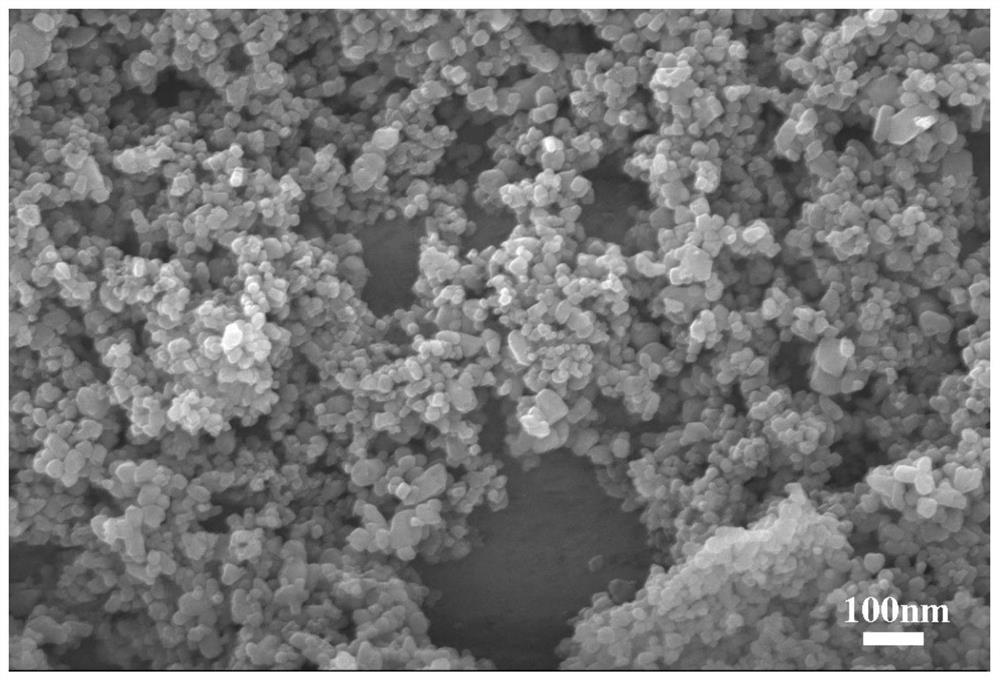

Embodiment 2

[0043] Change the specifications of the static pipeline mixer, the inner diameter of the mixer is 15mm, and there are 5 SMV type mixing units and 5 BKM type mixing units arranged alternately inside. Other conditions are with embodiment 1. The barium sulfate content, whiteness, volatile matter content at 105°C, average particle size and dispersibility of the obtained nano-barium sulfate product were measured, and the results are shown in Table 1.

Embodiment 3

[0045] Select industrial grade BaCl 2 As a water-soluble barium compound raw material, prepare BaCl with a concentration of 2.4mol / L in a barium liquid storage tank at 70°C 2 solution (saturation concentration). Select industrial grade Na 2 SO 4 As the sulfate raw material, prepare Na at a concentration of 3.2mol / L in a sulfate storage tank at 60°C 2 SO 4 solution (saturation concentration). The static pipeline mixing reactor is composed of two mixers connected in series. There are 8 SMV mixing units inside the front mixer with an inner diameter of 10mm. There are 10 Kenics pipeline mixer mixing units inside the back end mixer with an inner diameter of 10mm. The two mixers are connected by flanges. Two kinds of solutions are input in the pipeline mixing reactor through feed inlet, utilize barium liquid feeding device 3 and sulfate feeding device 5 to control the flow velocity of two kinds of solutions and be 1.5m / s, under this flow velocity, [Ba 2+ ]:[SO 4 2- ] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com