Online automatic cleaning electrostatic dust collector

An electrostatic precipitator and automatic cleaning technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of time-consuming and labor-consuming, secondary pollution, inconvenient manual cleaning, etc., and achieve simple operability, The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

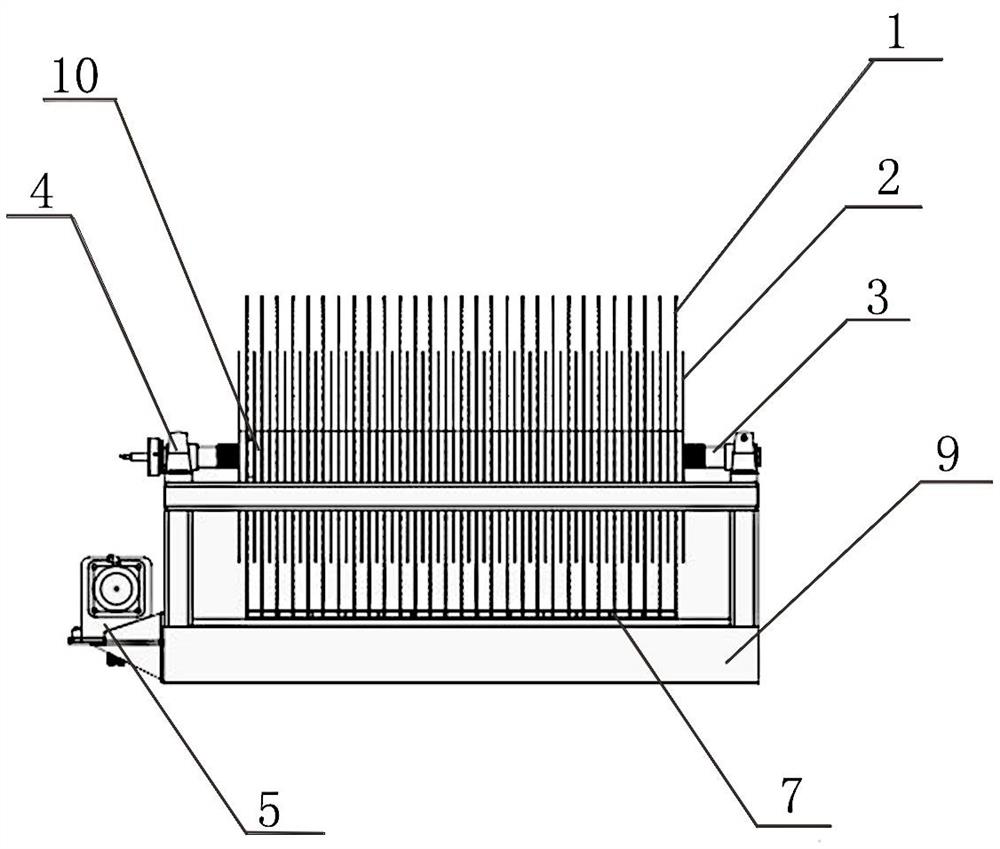

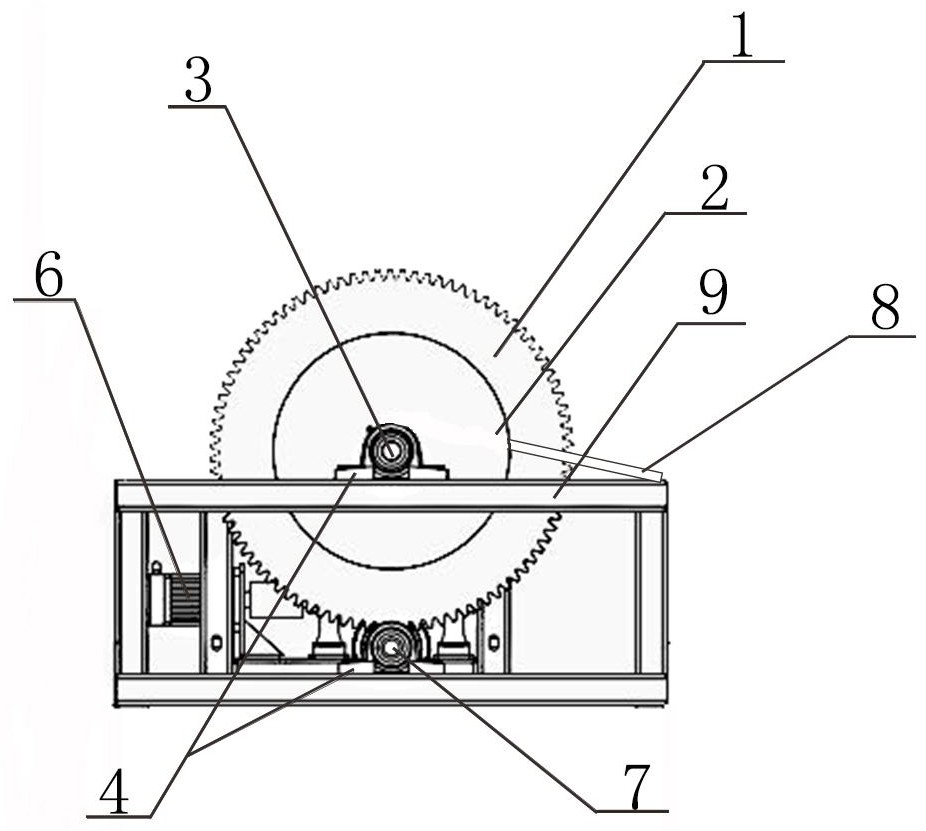

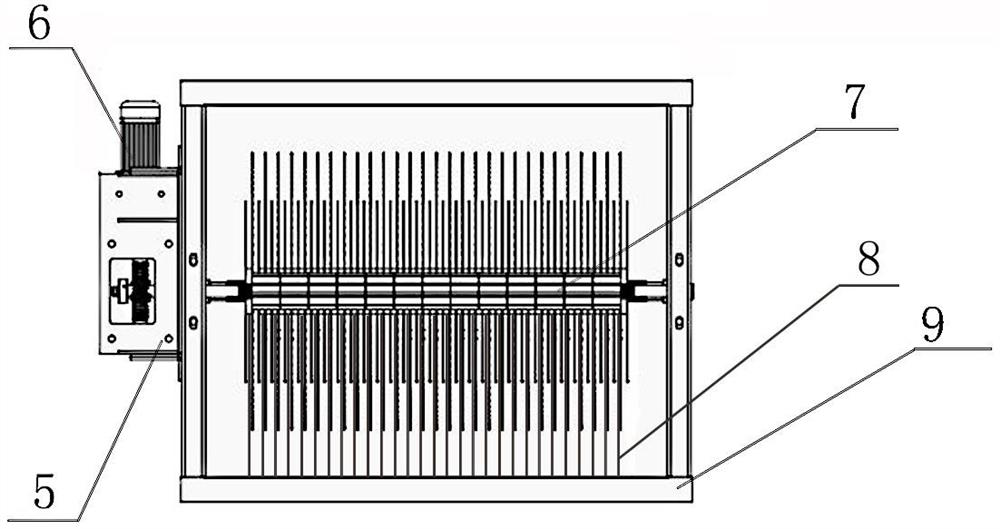

[0020] In this embodiment, as figure 1 As shown, the online automatic cleaning electrostatic precipitator includes positive plate 1, negative plate 2, center shaft 3, bearing seat 4, coupling 5, transmission motor 6, transmission long gear 7, insulating scraper 8, bracket 9 and etc. The distance tube 10; the positive plate 1 is a piece-type ring structure, and the inner edge is fixed on the equidistant tube 10 through the shaft pin; the negative plate 2 is a piece-type ring structure, and the inner edge is connected with the middle axis 3 fixed connection; the two ends of the central shaft 3 are respectively fixed on the bracket 9 through the bearing seat 4; the transmission long gear 7 is located directly below the central shaft 3, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com