Sensing type polymer water-based paint production line

A water-based coating and polymer technology, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of blockage of the feeding port, concentrated falling of materials, and increase the risk factor of workers, so as to increase the feeding efficiency, The effect of speeding up the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

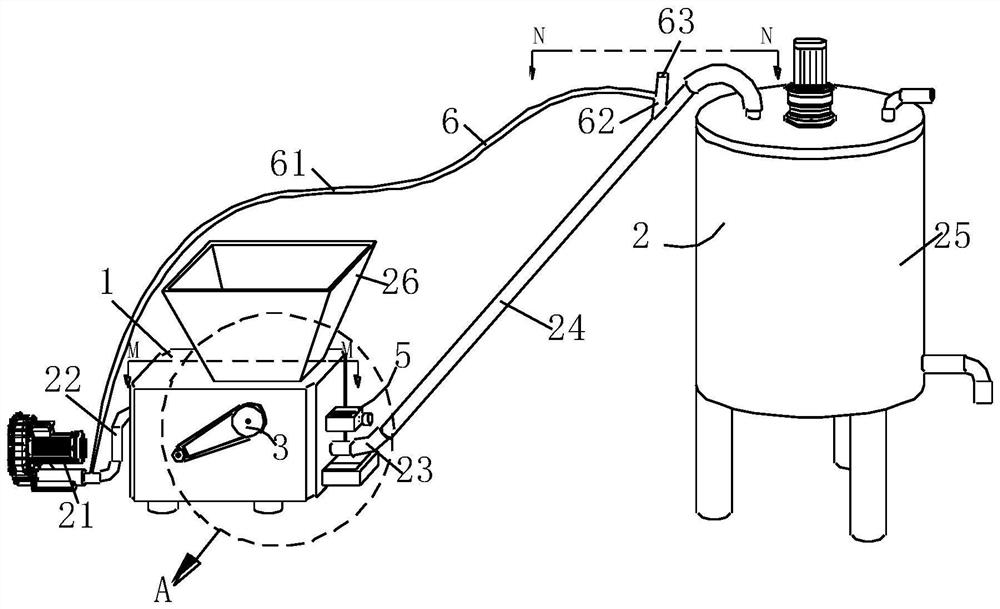

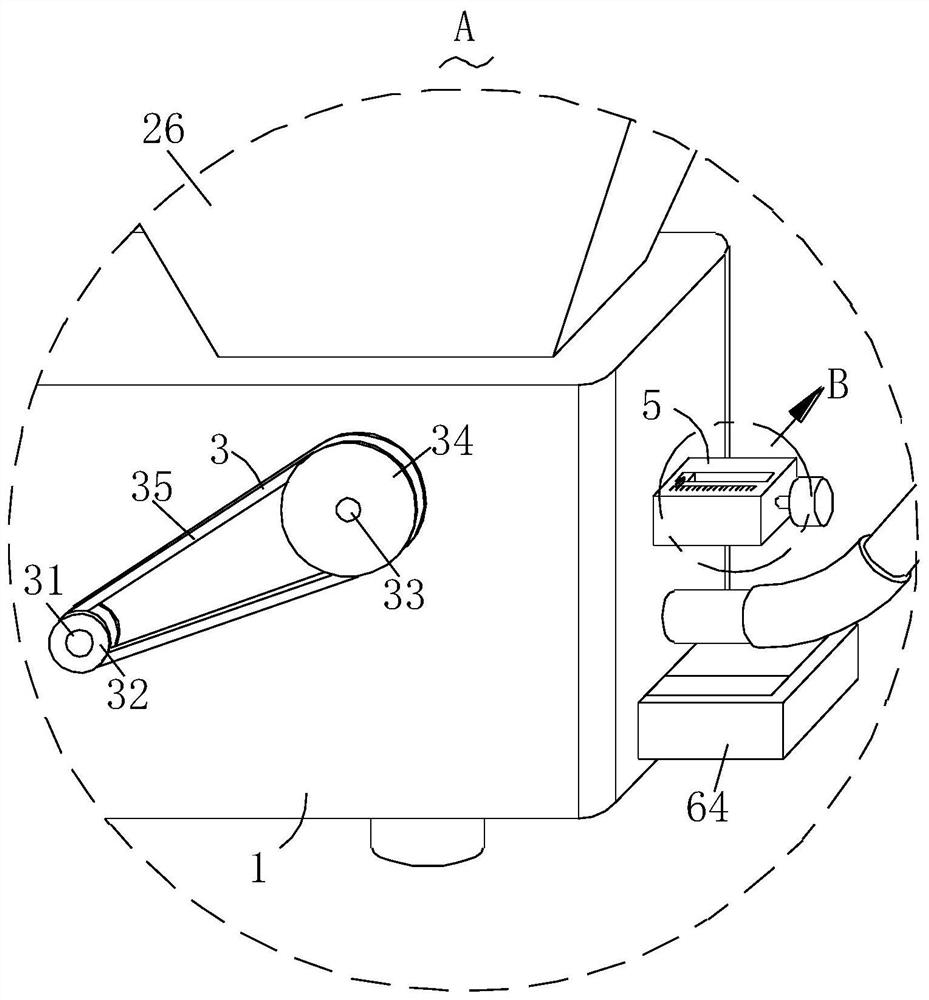

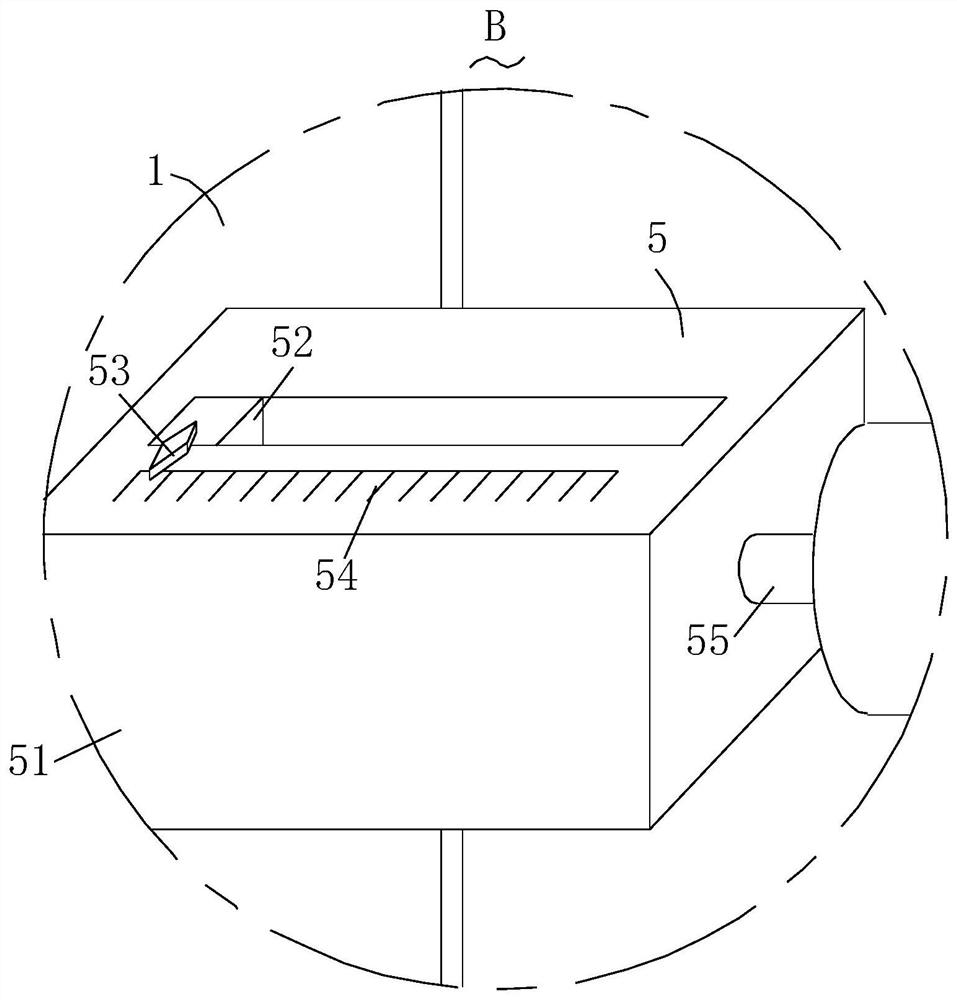

[0025] Such as Figure 1-Figure 7As shown, a kind of sensory polymer water-based paint production line of the present invention comprises casing 1, feeding structure 2, stirring structure 3, sealing structure 4, adjusting structure 5 and unloading structure 6, is used to play One end of the box body 1 that supports and installs other components and is convenient for feeding is installed with the material feeding structure 2 that can transport the material from the low place to the high place through the effect of wind force; The stirring structure 3 that stirs and feeds materials under the wind force of the feeding structure 2 is installed inside the box 1 to prevent the wind from blowing out from the feeding port of the feeding structure 2. A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com