Food production sterilization treatment equipment

A technology for sterilization treatment and food, which is applied in the direction of food science, etc., can solve the problems of waste of labor cost and time cost, and low efficiency of food sterilization treatment, so as to increase the storage capacity, save labor cost and time cost, and improve the processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

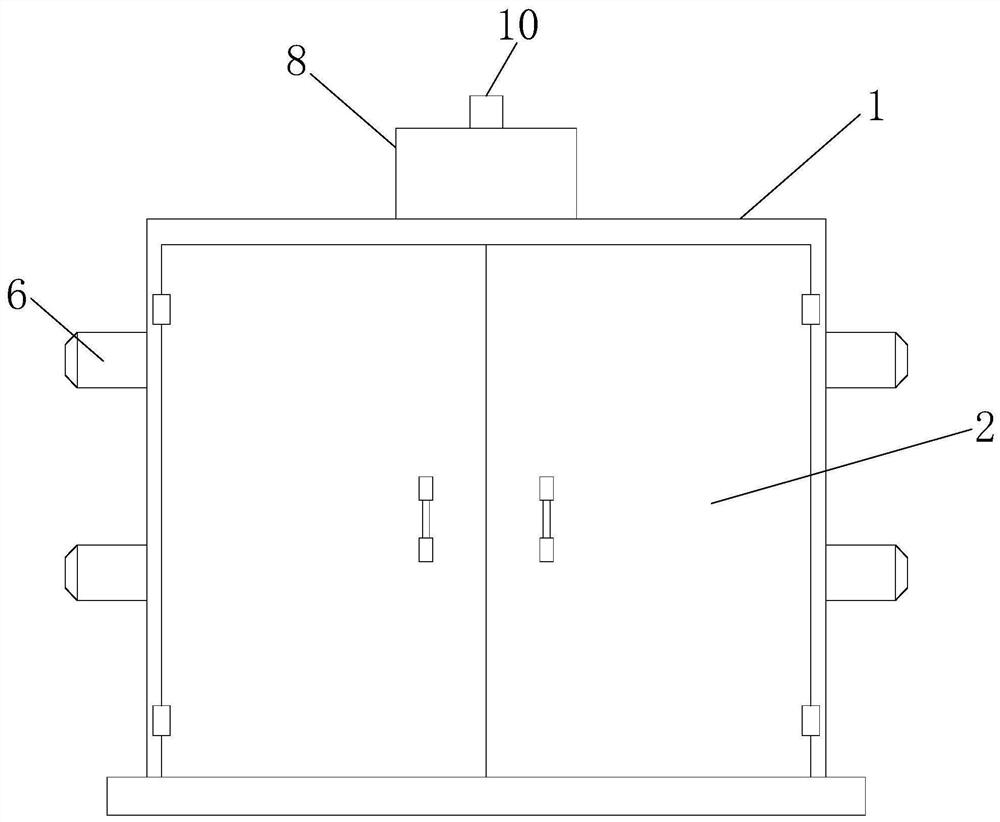

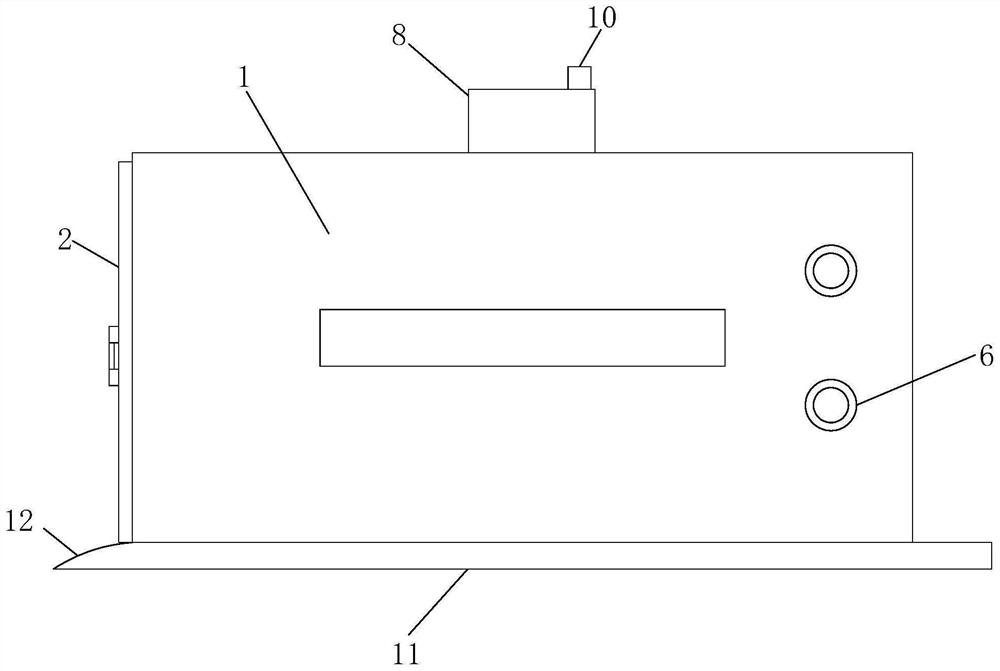

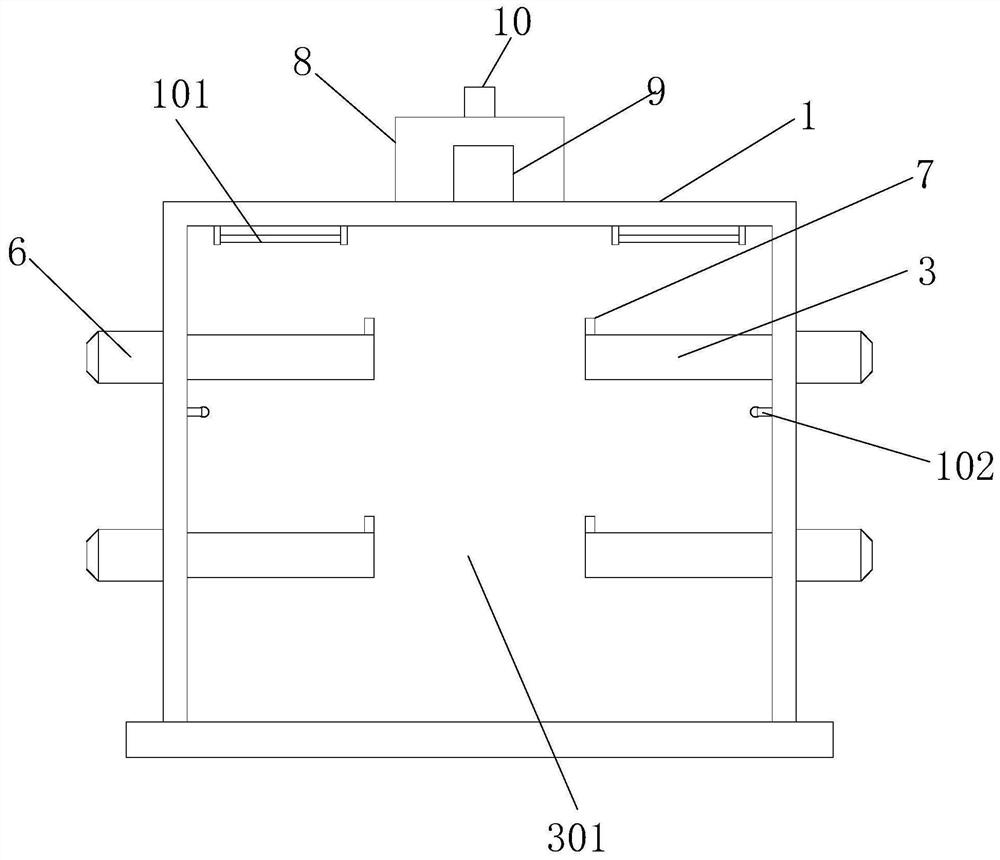

[0025] Refer Figure 1-4 , A food production sterilization treatment equipment, including the sterilization chamber 1 and the closed door 2 hinged to one end of the sterilization chamber 1 in the longitudinal direction, and the sterilization chassis 1 is separated on the top surface of the sterilization chamber with multiple sterilization lamps. 101. The sterilizing box 1 has a fixed frame 3 in the inner wall in the outer side of the longitudinal direction, and the fixed frame 3 and the fixed frame 3 have channel 301 in the lateral direction, and there are two drives of the internal interval rotation of the fixed frame 3. The shaft 4, the two drive shaft 4 drives the communication belt 5, and the outer shell wall of the sterilization box 1 is fixed to the motor 6 for driving the transmission belt 5, and the output shaft of the motor 6 is driven by one of the drive shafts 4 connect.

[0026] In the present invention, the motor 6 can drive the shaft 4 to rotate by the fixed frame 3, ...

Embodiment 2

[0028] Refer image 3 Further defined based on the embodiment 1, the number of fixed frame 3 on the inner wall of the sterilization box 1 is two in the longitudinal direction, and the two fixed frame 3 are disposed at the vertical direction, and the sterilization box is along the length. The inner wall of the direction in the direction is solidified with a sterilization lamp 2 102, and the sterilization lamp 2 10 is located between the two fixed frames 3 provided in the vertical direction interval.

[0029] In the present invention, the sterilization chamber 1 is disposed along the inner wall in the inner wall in the longitudinal direction, and the transmission belt 5 mounted in each fixed frame 3, which increases the amount of food in the food, which in turn passes. The lamp 22 can be sterilized for more comics.

Embodiment 3

[0031] Refer image 3 Further defined on the basis of Example 2, the top end of each of the fixed frames 3 is fixed from the side of the sterilization chamber 1, and there is a baffle 7.

[0032] In the present invention, the shaped food that is transmitted on the transmission belt 5 can be limited to the condition of the discharge process in the transmission tape 5 to be transmitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com