Battery cell connecting plate for battery module as well as preparation method and application of battery cell connecting plate

A battery module and connection board technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low aluminum row density, high copper density, unfavorable module lightweight, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

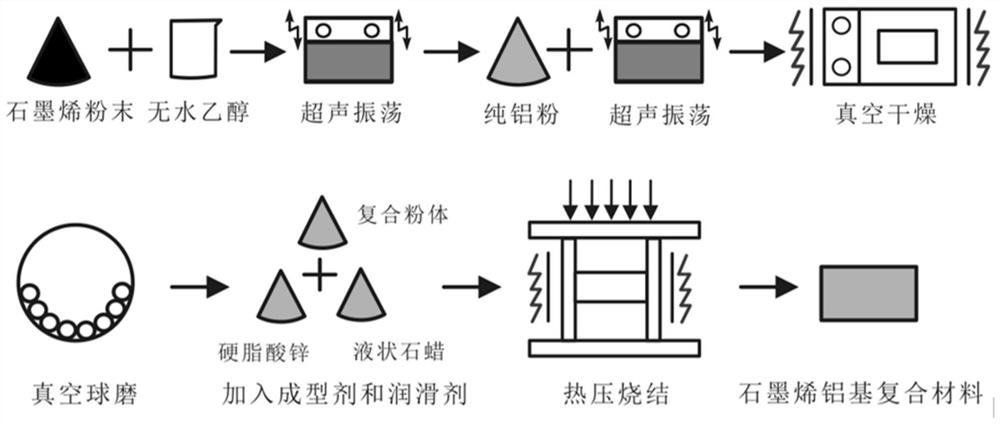

[0075] This embodiment provides a cell connecting plate for a battery module and a preparation method thereof, the preparation method comprising the following steps:

[0076] S1 powder mixing: weigh the graphene and add it into absolute ethanol, add 200ml of absolute ethanol for every 1g of graphene, ultrasonically oscillate at an ultrasonic frequency of 60KHz for 20min, then let stand for 10min, add aluminum powder (particle size D50 is 15 μm), the mass ratio of aluminum powder to graphene is 199:1, and ultrasonic vibration is performed for 90 minutes at an ultrasonic frequency of 60KHz to obtain a composite material;

[0077] S2 Vacuum drying: Put the composite material obtained after powder mixing in a vacuum drying oven for vacuum drying, set the temperature at 120°C, the vacuum degree at -0.06MPa, and set the time at 2h. After vacuum drying, the residual alcohol is evaporated at the same time It can prevent the powder from being oxidized again during the drying process; ...

Embodiment 2

[0084] This embodiment provides a cell connecting plate for a battery module and a preparation method thereof, the preparation method comprising the following steps:

[0085] S1 powder mixing: weigh the graphene and add it into absolute ethanol, add 200ml of absolute ethanol for every 1g of graphene, ultrasonically oscillate at an ultrasonic frequency of 60KHz for 20min, then let stand for 10min, add aluminum powder (particle size D50 is 15 μm), the mass ratio of aluminum powder to graphene is 99:1, and ultrasonic vibration is performed at an ultrasonic frequency of 60KHz for 90min to obtain a composite material;

[0086] S2 Vacuum drying: Put the composite material obtained after powder mixing in a vacuum drying oven for vacuum drying, set the temperature at 120°C, the vacuum degree at -0.06MPa, and set the time at 2h;

[0087] S3 Vacuum ball milling: Vacuum ball mill the dried composite powder, set the rotation speed to 200rpm, set the ball milling time to 2h, and set the va...

Embodiment 3

[0093] This embodiment provides a cell connecting plate for a battery module and a preparation method thereof, the preparation method comprising the following steps:

[0094]S1 powder mixing: weigh the graphene and add it into absolute ethanol, add 200ml of absolute ethanol for every 1g of graphene, ultrasonically oscillate at an ultrasonic frequency of 60KHz for 20min, then let stand for 10min, add aluminum powder (particle size D50 is 15 μm), the mass ratio of aluminum powder and graphene is 197:3, ultrasonic vibration 90min under the ultrasonic frequency of 60KHz, obtains composite material;

[0095] S2 Vacuum drying: Put the composite material obtained after powder mixing in a vacuum drying oven for vacuum drying, set the temperature at 120°C, the vacuum degree at -0.06MPa, and set the time at 2h;

[0096] S3 Vacuum ball milling: Vacuum ball mill the dried composite powder, set the rotation speed to 200rpm, set the ball milling time to 2h, and set the vacuum degree to -0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com