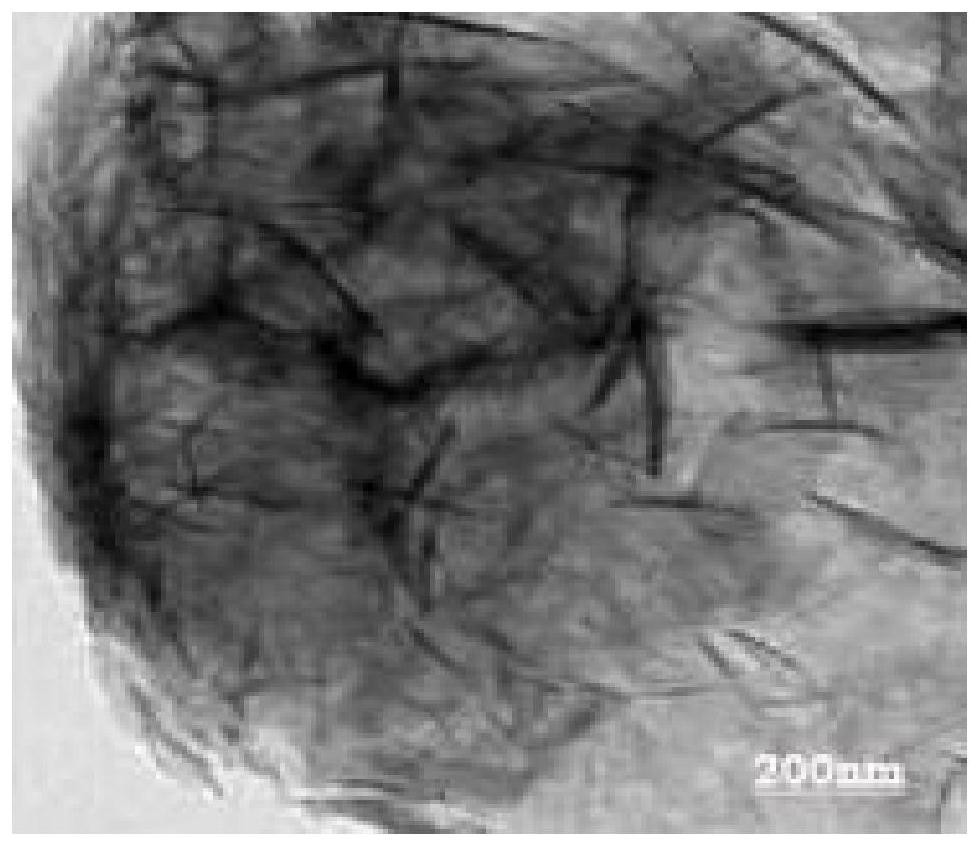

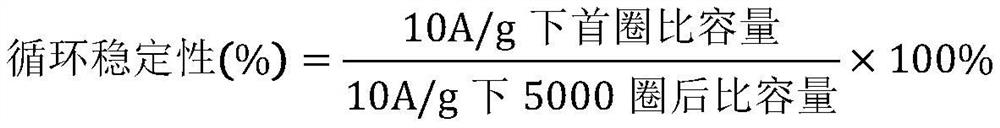

ZIF-67@LDHs electrode material applied to supercapacitor and preparation method thereof

A ZIF-67, supercapacitor technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve problems such as stacking and poor conductivity, and achieve increased ratio Effects of surface area, improved electrical conductivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for a ZIF-67@LDHs electrode material applied to a supercapacitor, specifically comprising the following steps:

[0024] S1: Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) added to deionized water, ultrasonically dissolved, and then added urea and ammonium fluoride (NH 4 F), stirring at room temperature for 30min to obtain a precursor solution, in which urea and ammonium fluoride (NH 4 The molar ratio of F) is 1.22:0.69.

[0025] S2: Move the precursor solution to a high-pressure reactor, then react at 120°C for 6.5 hours, cool, then sonicate for 10min, filter, wash with deionized water, add it to ethylene glycol dimethyl ether again, and sonicate for 30min , and then filtered and dried at 65°C to obtain LDHs material, in which the molar ratio of aluminum nitrate, cobalt nitrate and urea was 0.55:0.69:1.

[0026] S3: Add the LDHs material in step S2 to the methanol solution, then add cobalt nitrate, and then so...

Embodiment 2

[0028] A preparation method for a ZIF-67@LDHs electrode material applied to a supercapacitor, specifically comprising the following steps:

[0029] S1: Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) added to deionized water, ultrasonically dissolved, and then added urea and ammonium fluoride (NH 4 F), stirring at room temperature for 50min to obtain a precursor solution, in which urea and ammonium fluoride (NH 4 The molar ratio of F) is 2.4:1.32.

[0030]S2: Move the precursor solution to a high-pressure reactor, then react at 140°C for 10 hours, cool, then sonicate for 20min, filter, wash with deionized water, add it to ethylene glycol dimethyl ether again, and sonicate for 45min, Then it was filtered and dried at 80°C to obtain LDHs material, in which the molar ratio of aluminum nitrate, cobalt nitrate and urea was 1.15:1.25:1.

[0031] S3: Add the LDHs material in step S2 to the methanol solution, then add cobalt nitrate and then soni...

Embodiment 3

[0033] A preparation method for a ZIF-67@LDHs electrode material applied to a supercapacitor, specifically comprising the following steps:

[0034] S1: Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) added to deionized water, ultrasonically dissolved, and then added urea and ammonium fluoride (NH 4 F), stirring at room temperature for 40min to obtain a precursor solution, in which urea and ammonium fluoride (NH 4 The molar ratio of F) is 1.96:1.21.

[0035] S2: Move the precursor solution to a high-pressure reactor, then react at 130°C for 8 hours, cool, then sonicate for 15min, filter, wash with deionized water, add it to ethylene glycol dimethyl ether again, and sonicate for 40min, Then it was filtered and dried at 70°C to obtain LDHs material, in which the molar ratio of aluminum nitrate, cobalt nitrate and urea was 0.94:1.13:1.

[0036] S3: Add the LDHs material in step S2 to the methanol solution, then add cobalt nitrate and then son...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com