A method and device for producing a diamond wire saw

A technology of diamond wire saw and corundum, applied in the direction of coating, electrolytic coating, etc., can solve the problems of unguaranteed pass rate, inability to achieve suspension state, difficulty of corundum, etc., so as to avoid bad cutting marks, reduce the quantity of corundum, The effect of reducing input and turnover costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

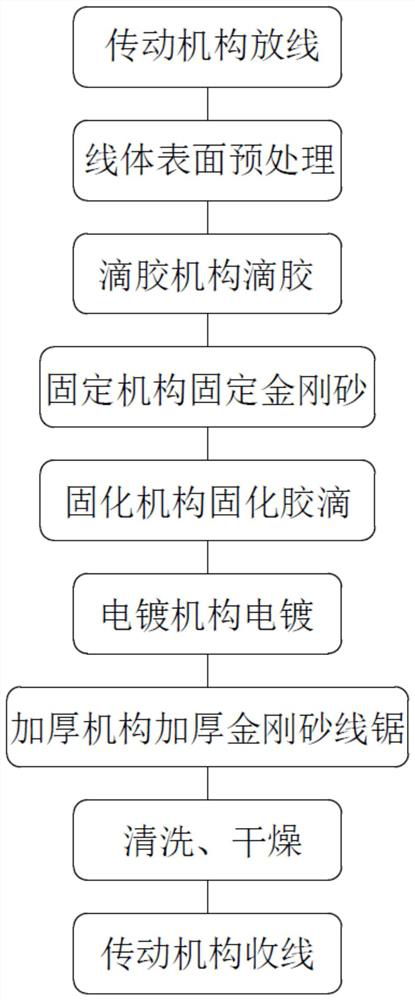

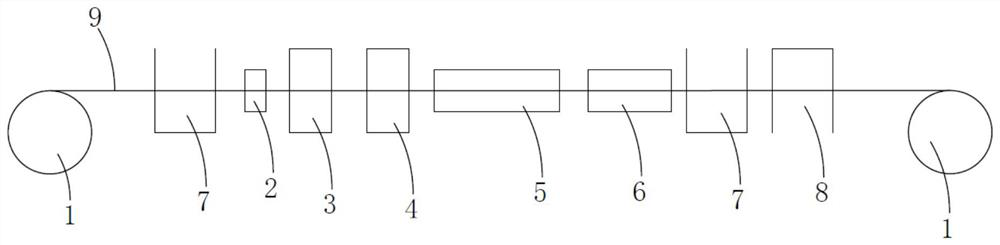

[0046] see figure 1

[0047] A method for producing a diamond wire saw, comprising the following steps:

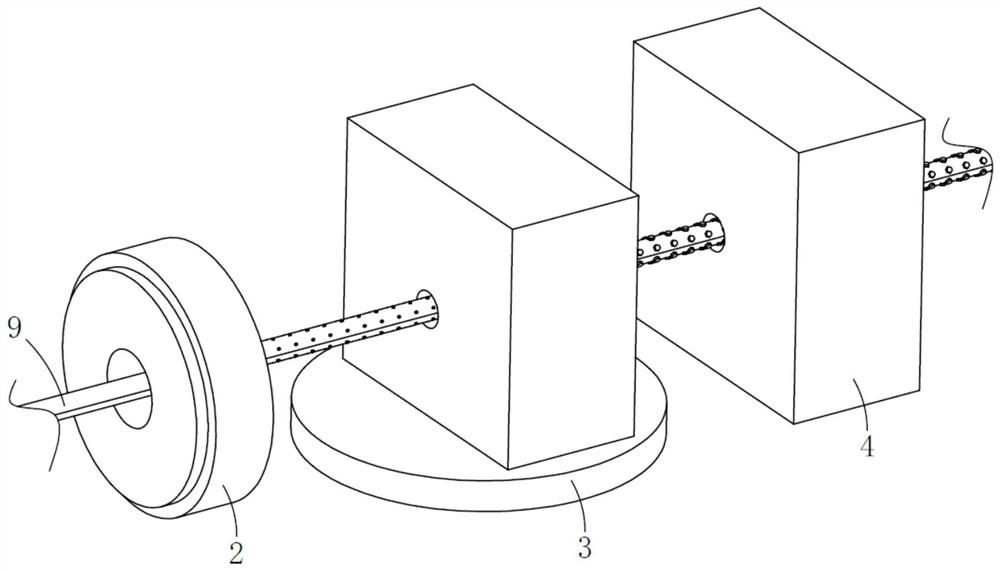

[0048] S1: The conveying mechanism 1 sends the wire body 9 into the dispensing mechanism 2 for dispensing;

[0049] S2: The glue dispensing mechanism 2 dispenses glue on the wire body 9, so that the glue droplets are evenly distributed on the wire body 9, and the conveying mechanism 1 sends the wire body 9 stained with the glue drop into the fixing mechanism 3;

[0050] The step S2 includes the drive circuit of the piezoelectric unit 23 of the glue dispensing mechanism 2 giving electric pulses to the pipeline 21, so that the pipeline 21 is deformed by pressure, the glue in the pipeline 21 is squeezed, and the glue on the first nozzle 22 overcomes the surface tension to form A drop of glue is sprayed onto the surface of the wire body 9 .

[0051] The glue spraying is controlled by the piezoelectric unit 23, the piezoelectric crystal works fast, and the glue spraying spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com