Magnesium-nitrogen-doped carbon dots, preparation method thereof and application of magnesium-nitrogen-doped carbon dots in improvement of photosynthesis of plants

A carbon dot, magnesium nitrogen technology, applied in the field of nanomaterial biological effect research, can solve the problems of limited light capture ability, photosynthetic system activity, low plant photosynthesis efficiency, etc., to promote synthesis and metabolism, improve photosynthetic activity, and accelerate growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Preparation of magnesium nitrogen doped carbon dots (Mg,N-CDs): Mg,N-CDs were prepared using citric acid, ethanolamine and magnesium hydroxide as raw materials by a one-step hydrothermal method, and the molar ratio was 1:0.2:0.35 Citric acid, ethanolamine and magnesium hydroxide were dissolved in ultrapure water, and ultrasonically treated for 30 minutes. Magnesium hydroxide, which is slightly soluble in water, can be completely dissolved due to the chelating effect of citric acid. Then, the mixed solution obtained by ultrasonic treatment was poured into a 50 mL polytetrafluoroethylene reactor lining, loaded into the reactor, and reacted at 200° C. for 6 h. After the reaction kettle was lowered to room temperature, the brown product was filtered through a filter head with a pore size of 0.22 μm, and then dialyzed with a dialysis bag (MW 100-500) for 12 hours, and the dialysate was ultrapure water. After freeze-drying, magnesium-nitrogen doped carbon dots (Mg, N-CDs) can...

Embodiment 2

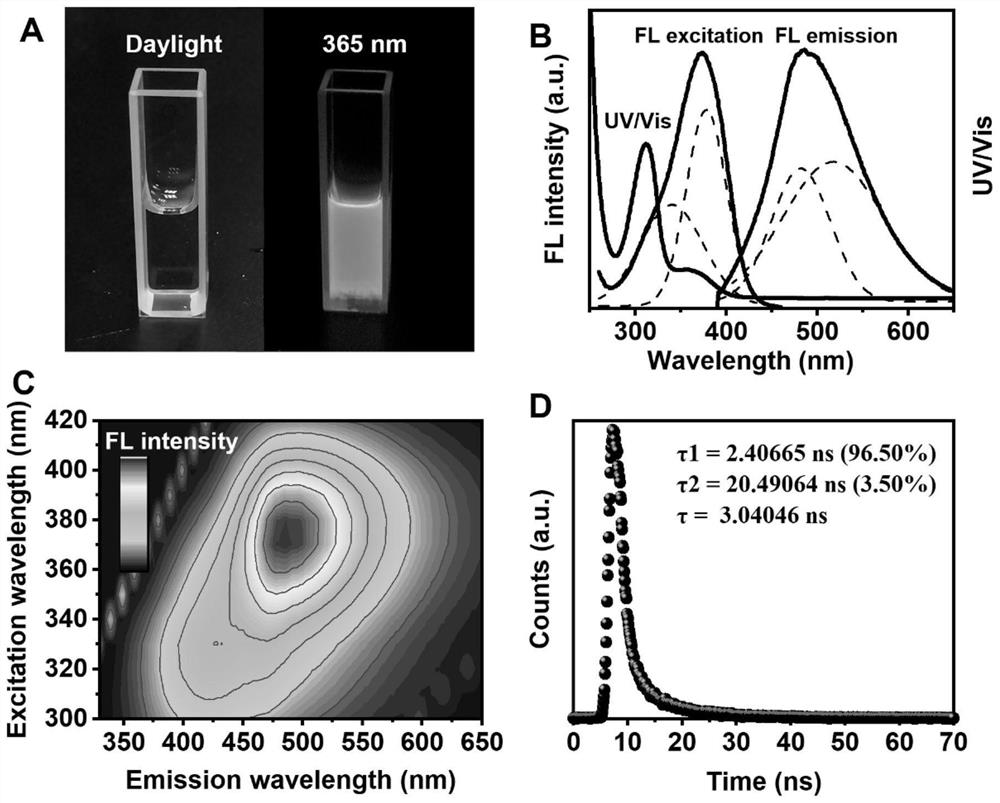

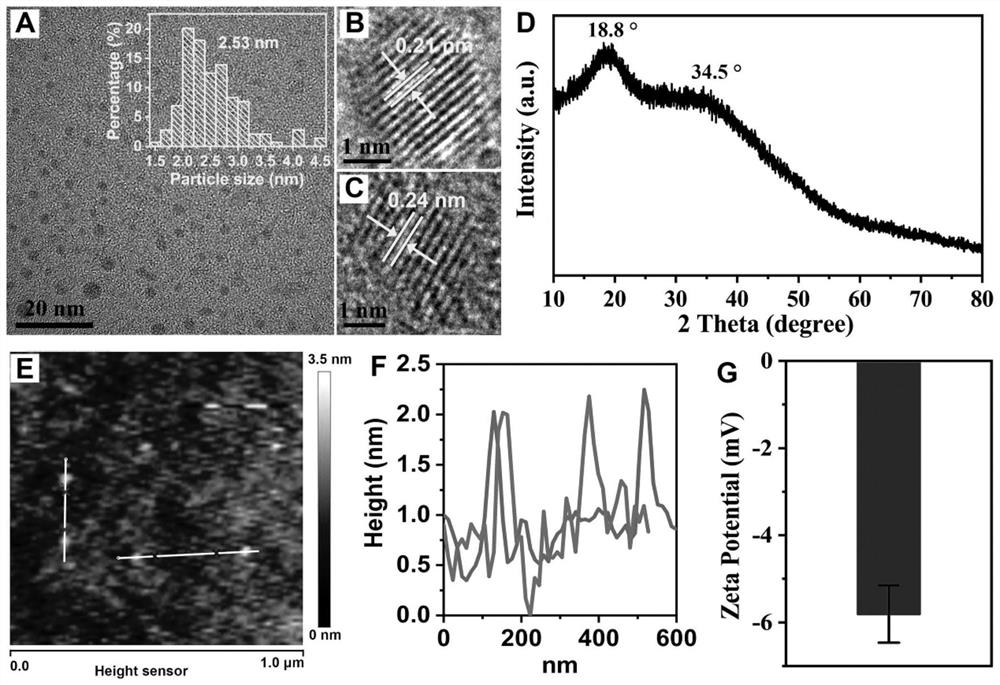

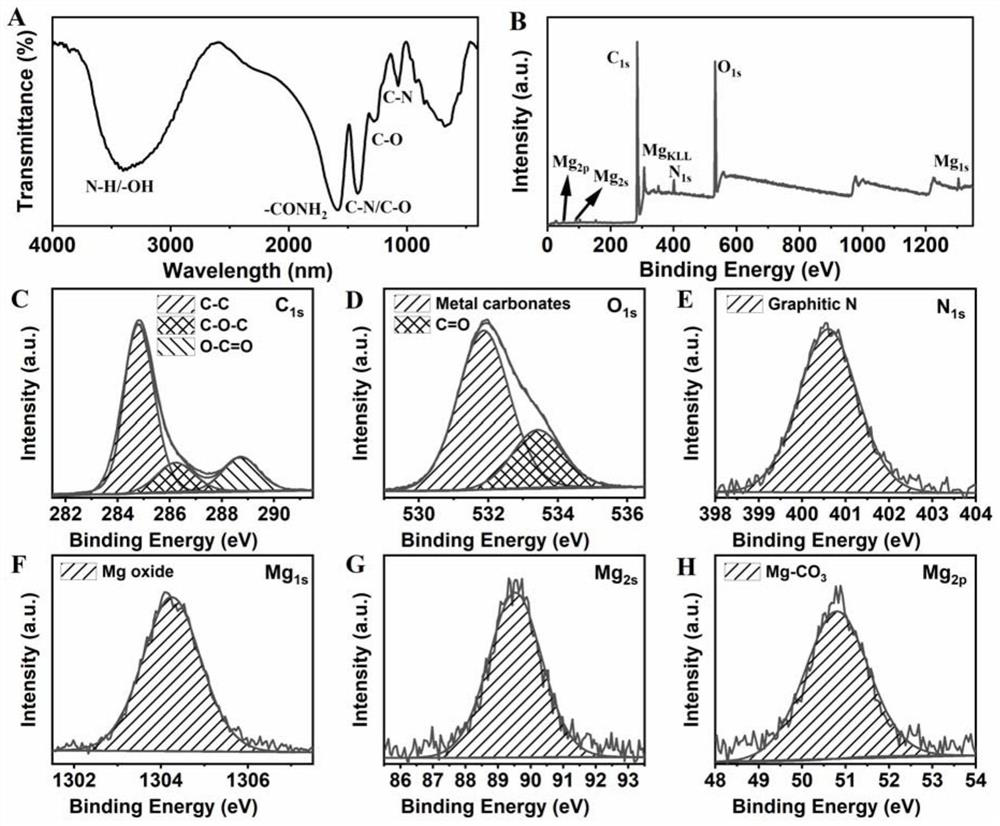

[0033] The magnesium nitrogen doped carbon point (Mg, N-CDs) obtained in embodiment 1 is characterized:

[0034] Characterization method: The morphology of Mg, N-CDs was observed by JEM-2100F field emission transmission electron microscope (TEM) and SPA-400 atomic force microscope (AFM). Characterization was performed using a Thermo Scientific Nicolet 6700FTIR spectrometer and a Thermo Scientific K-Alpha X-ray photoelectron spectroscopy (XPS). The fluorescence emission spectra and fluorescence lifetime decay curves of Mg, N-CDs were measured by F-7000Hitachi and FLS1000-stm fluorescence spectrometers, respectively. A PerkinElmer UV-Vis spectrophotometer (Lambda 750) was used to measure the UV-Vis light absorption curve of Mg, N-CDs. At the same time, we also used TGA-DSC thermogravimetry (Labsys STA) coupled with mass spectrometry (LC-DZOOM Pro) (TG-MS) to determine the thermal decomposition curve and product composition of Mg, N-CDs from room temperature to 800 °C. Finally,...

Embodiment 3

[0042] Effects of the magnesium and nitrogen doped carbon dots (Mg, N-CDs) obtained in Example 1 on the growth of rice plants:

[0043] The treatment method of magnesium nitrogen doped carbon dots on rice plants: first use 75% ethanol solution to sterilize the rice seeds (Huahang No. 31), wash thoroughly with deionized water, spread them evenly in the germination tray, and add 50% concentration of nutrients cultured at 30°C in the dark. After 3 days, the cover of the germination tray was uncovered, and the seeds germinated substantially completely, and were placed in a greenhouse (22-30° C., 70% relative humidity, 400 μmol m -2 ·s -1 The light intensity, the photoperiod is 16h light / 8h dark) and continue to cultivate until the 7th day. Rice seedlings with uniform growth state were selected and transplanted into black square plastic boxes, 12 plants per box, and the nutrient solution in the box was replaced twice a week. Different concentrations of Mg,N-CDs (50, 100 and 300 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com