A kind of preparation method of water-soluble capsanthin and product thereof

A capsanthin and water-soluble technology, applied in the field of preparation of water-soluble capsanthin, can solve problems such as damage to human health, environmental pollution, poor stability of vesicle encapsulation rate, etc., achieve good stability, improve application scope, Improve water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

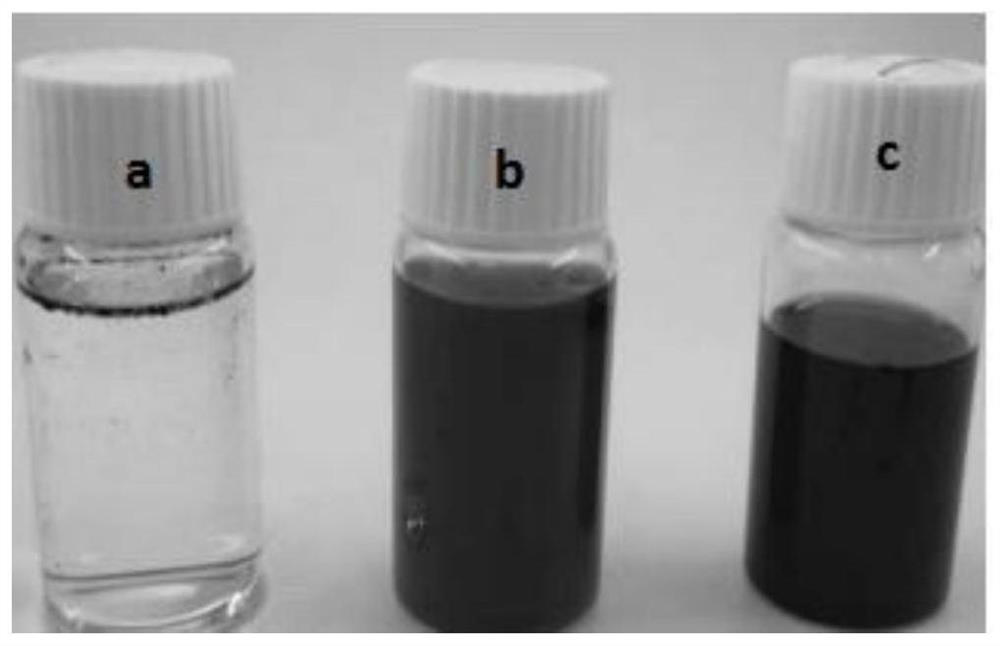

Image

Examples

Embodiment 1

[0030] The preparation of water-soluble capsanthin comprises the following steps:

[0031] (1) Saponification of capsanthin: Add 5wt.% sodium hydroxide solution to capsanthin, heat 75vol.% ethanol solution at 55°C for 2h, and elute the saponified capsanthin to neutral .

[0032] (2) Weigh soybean protein isolate and soybean polysaccharide according to the mass ratio of 1:1, add water to make 10wt% soybean protein isolate solution and 10wt% soybean polysaccharide solution respectively, stir it at 25°C for 4h, put it in 4°C Hydrate overnight in the refrigerator. Mix the two hydrated solutions and put them in a water bath at 60°C for 72 hours to react for Maillard reaction. Take them out after the reaction is completed, lower the temperature to room temperature with ice water, centrifuge for 30 minutes, and take out the supernatant for dialysis After freeze-drying, the granular carrier is obtained;

[0033] The degree of covalent grafting of the carrier was tested to obtain a ...

Embodiment 2

[0036] The preparation of water-soluble capsanthin, the steps are as follows:

[0037] (1) Saponification of capsanthin: Add 5wt.% sodium hydroxide solution to capsanthin, heat 75vol.% ethanol solution at 55°C for 2h, and elute the saponified capsanthin to neutral .

[0038] (2) Weigh soybean protein isolate and soybean polysaccharide according to the mass ratio of 1:1, add water to make 10wt% soybean protein isolate solution and 10wt% soybean polysaccharide solution respectively, stir it at 25°C for 4h, put it in 4°C Hydrate overnight in the refrigerator. Mix the two hydrated solutions and put them in a water bath at 60°C for 72 hours to react for Maillard reaction. Take them out after the reaction is completed, lower the temperature to room temperature with ice water, centrifuge for 30 minutes, and take out the supernatant for dialysis After freeze-drying, the granular carrier is obtained;

[0039] (3) Add water to the carrier obtained in step (2) to prepare an aqueous carr...

Embodiment 3

[0041] The preparation of water-soluble capsanthin comprises the following steps:

[0042] (1) Saponification of capsanthin: Add 5wt.% sodium hydroxide solution to capsanthin, heat 75vol.% ethanol solution at 55°C for 2h, and elute the saponified capsanthin to neutral .

[0043] (2) Weigh soybean protein isolate and soybean polysaccharide according to the mass ratio of 1:1, add water to make 10wt% soybean protein isolate solution and 10wt% soybean polysaccharide solution respectively, stir it at 25°C for 4h, put it in 4°C Hydrate overnight in the refrigerator. Mix the two hydrated solutions and put them in a water bath at 60°C for 72 hours to react for Maillard reaction. Take them out after the reaction is completed, lower the temperature to room temperature with ice water, centrifuge for 30 minutes, and take out the supernatant for dialysis After freeze-drying, the granular carrier is obtained;

[0044] (3) Add water to the carrier obtained in step (2) to prepare an aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com