A warm viscosity-increasing active polymer viscosity reducer and its preparation method and application

A technology of active polymer and viscosity reducer, which is applied in the field of temperature-increased active polymer viscosity-reducer and its preparation, can solve the problem of low molecular weight of temperature-increased polymers, less temperature-sensitive monomers, and temperature-increased viscosity-increased polymers. Can not use heavy oil viscosity reducer and other problems, to achieve the effect of improving injection capacity, improving recovery factor, and good heavy oil viscosity reducing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In one or some embodiments of the present disclosure, a method for preparing a warm viscosity-increasing active polymer is provided, comprising the following steps: (1) Synthesis of a temperature-sensitive monomer: dissolving hydrophilic and hydrophobic monomers in deionized water, In a nitrogen environment, an initiator and a chain transfer agent are added to react to obtain a temperature-sensitive monomer containing terminal amine groups;

[0044](2) Synthesis of warm viscosity-increasing polymer: dissolve the temperature-sensitive monomer and partially hydrolyzed polyacrylamide in deionized water, prepare a mixed solution with a certain mass concentration, adjust the pH to neutrality, and add a set amount of condensing agent After reacting for a period of time, the reactant is washed and dried to a constant weight to obtain a warm viscosity-increasing polymer.

[0045] Among them, it should be understood that in step (1), the role of the terminal amine group is to ma...

Embodiment 1

[0069] This embodiment provides the preparation process of the temperature-sensitive monomer, which includes the following steps: dissolving acrylamide and diacetone acrylamide in deionized water in a molar ratio of 4.5:5.5 and 5.5:4.5, and adding potassium persulfate as a The initiator, mercaptoethylamine hydrochloride as a chain transfer agent, was reacted at 30° C. for 6 hours to obtain temperature-sensitive monomers AM-DAAM-1 and AM-DAAM-2 containing terminal amine groups.

Embodiment 2

[0071] This embodiment provides the preparation process of the temperature-viscosity-increasing polymer viscosity reducers PAAD-1 and PAAD-2, including the following steps: dissolving the temperature-sensitive monomers AM-DAAM-1 and AM-DAAM-2 in water, Add a partially hydrolyzed polyacrylamide aqueous solution (the molar ratio of temperature-sensitive monomer and partially hydrolyzed polyacrylamide is 10:1), make up an aqueous solution with a mass concentration of 3%, adjust the pH to neutrality, add a condensing agent, and at 25 ° C The reaction was taken out for 24 hours. The reactants were washed with absolute ethanol and dried in a 45°C incubator to constant weight. That is, the warm viscosity-increasing polymer viscosity reducers PAAD-1 and PAAD-2 are obtained.

[0072] The response temperature of PAAD-1 is 55℃, and the response temperature of PAAD-2 is 45℃.

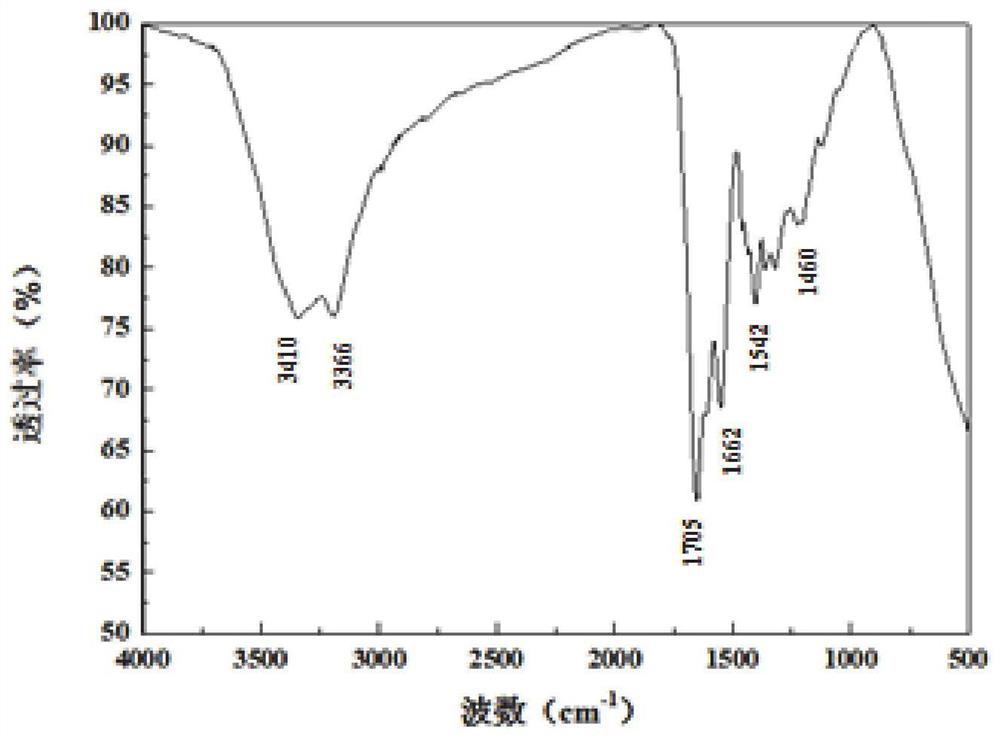

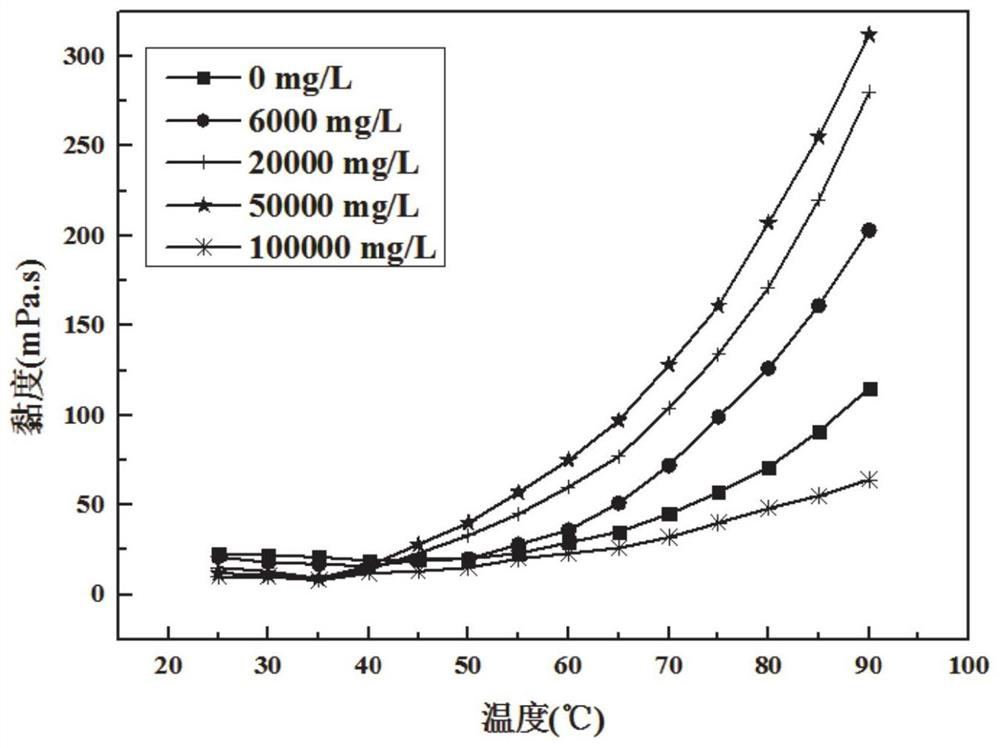

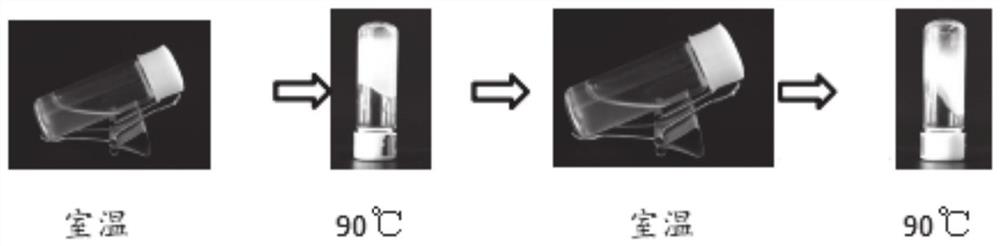

[0073] Infrared spectroscopic analysis of warm viscosity-increasing polymer viscosity reducer PAAD-2, see figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com