Homogeneous carbonization preparation method of magnesium slag cementing material for smelting magnesium by silicothermic method

A cementitious material, silicothermal technology, applied in climate sustainability, cement production, sustainable waste disposal, etc., can solve the problems of insufficient internal reaction, long reaction time of magnesium slag cementitious material, uneven reaction, etc. Achieve the effect of saving energy consumption, conducive to popularization and application, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

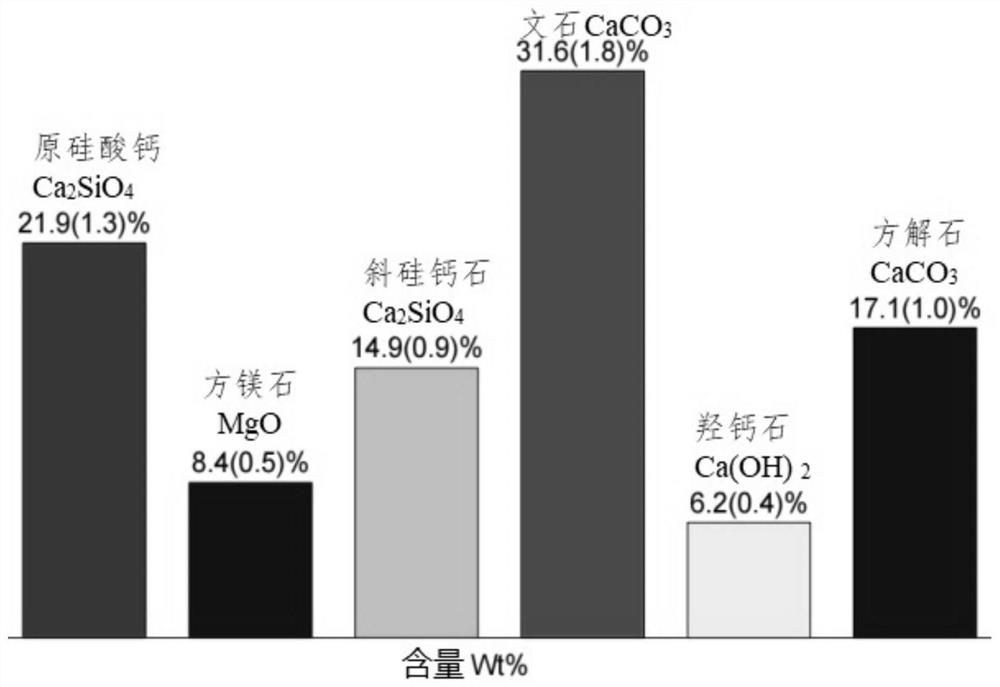

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] Step 1. After the magnesium slag produced by silithermal magnesium smelting is out of the furnace, the temperature is rapidly cooled to room temperature by air cooling to obtain cooled magnesium slag; the rapid cooling is from the furnace temperature to 200° C. and then to room temperature within 2 minutes;

[0040] Step 2, put the cooled magnesium slag obtained in step 1 into a ball mill for ball milling, then sieve to collect the undersize magnesium slag; the rotating speed of the ball mill is 45r / min, and the time is 30min; 100 mesh screen;

[0041] Step 3. Mix the undersize magnesium slag obtained in step 2 with water at a speed of 65r / min for 270s to gather into agglomerates, and then put it into a mold to form a magnesium slag cemented billet; the undersize The mass ratio of magnesium slag to water is 0.3:1;

[0042] Step 4, placing the magnesium slag gelled blank obtained in step 3 in a curing room with a h...

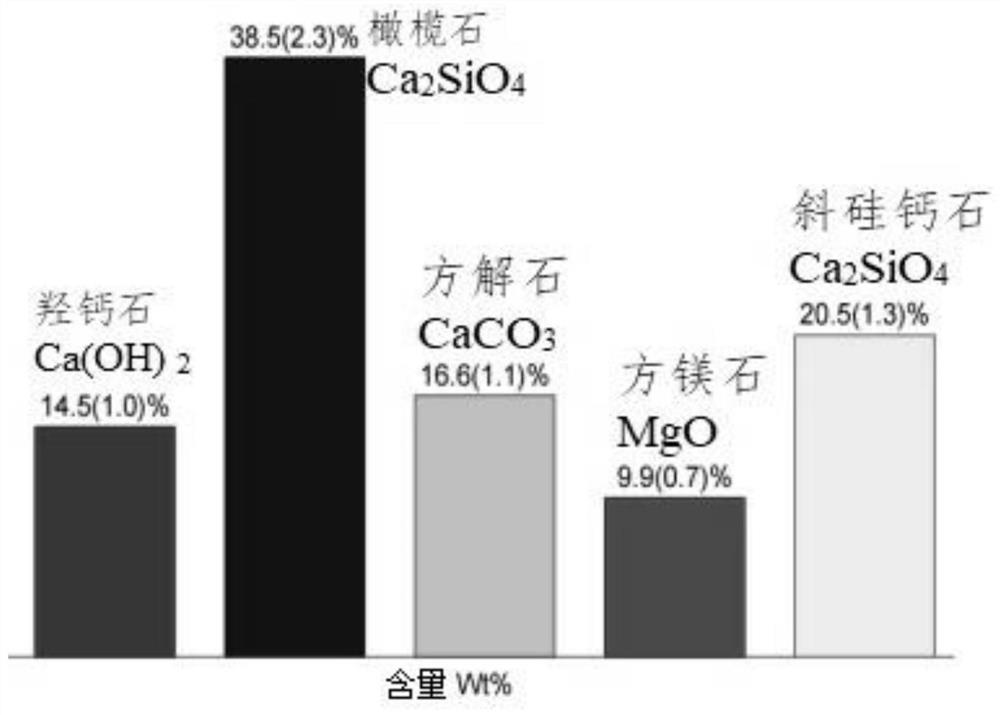

Embodiment 2

[0076] This embodiment includes the following steps:

[0077] Step 1. After the magnesium slag produced by silithermal magnesium smelting is out of the furnace, the temperature is rapidly cooled to room temperature by air cooling to obtain cooled magnesium slag; the rapid cooling is from the furnace temperature to 200° C. and then to room temperature within 2 minutes;

[0078] Step 2, put the cooled magnesium slag obtained in step 1 into a ball mill for ball milling, then sieve to collect the undersize magnesium slag; the rotating speed of the ball mill is 45r / min, and the time is 30min; 100 mesh screen;

[0079] Step 3. Mix the undersize magnesium slag obtained in step 2 with water at a speed of 65r / min for 270s to gather into agglomerates, and then put it into a mold to form a magnesium slag cemented billet; the undersize The mass ratio of magnesium slag to water is 0.3:1;

[0080] Step 4, placing the magnesium slag gelled blank obtained in step 3 in a curing room with a h...

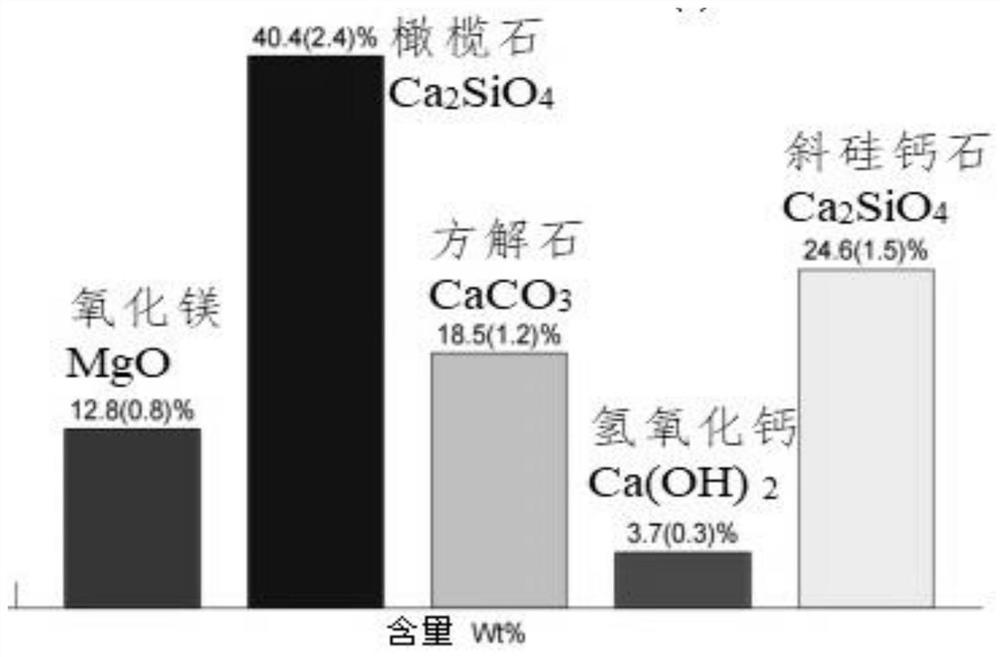

Embodiment 3

[0103] This embodiment includes the following steps:

[0104] Step 1. After the magnesium slag produced by silithermal magnesium smelting is out of the furnace, the temperature is rapidly cooled to room temperature by air cooling to obtain cooled magnesium slag; the rapid cooling is from the furnace temperature to 200° C. and then to room temperature within 2 minutes;

[0105] Step 2, put the cooled magnesium slag obtained in step 1 into a ball mill for ball milling, then sieve to collect the undersize magnesium slag; the rotating speed of the ball mill is 38r / min, and the time is 60min; 100 mesh screen;

[0106] Step 3. Mix the undersize magnesium slag obtained in step 2 with water at a speed of 75r / min for 240s to gather into agglomerates, and then put it into a mold to form a magnesium slag cemented billet; the undersize The mass ratio of magnesium slag to water is 0.2:1;

[0107] Step 4, placing the magnesium slag gelled blank obtained in step 3 in a curing room with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com