Automatic machining production line for plate parts

An automatic processing and production line technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to adapt, unfavorable unified management, and large number of machine tools, so as to improve production efficiency, reduce manufacturing costs, and ensure production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The automatic processing line for plate parts of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

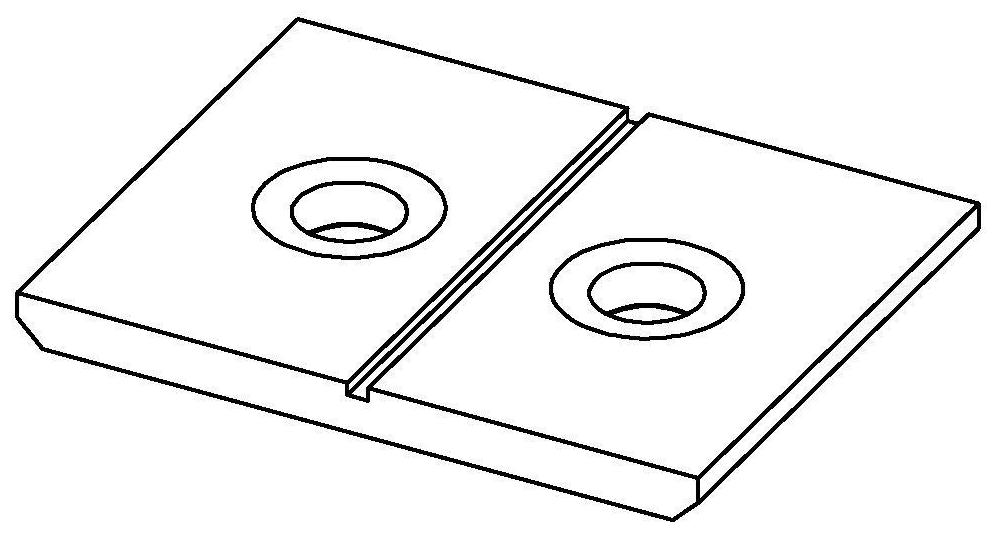

[0035] For the processed wear plate product of the present invention, the final formed structure is as follows image 3 As shown, it includes a plate of nylon material, two through holes processed on the plate, a strip groove processed between the two through holes, and a chamfer processed at the through hole of the plate. That is to say, during processing, it is necessary to drill holes on the plate, turn the upper surface and the lower surface of the plate, turn the four side surfaces of the plate, and process the strip between the two through holes on the plate. Shaped grooves and chamfering of through holes, etc.

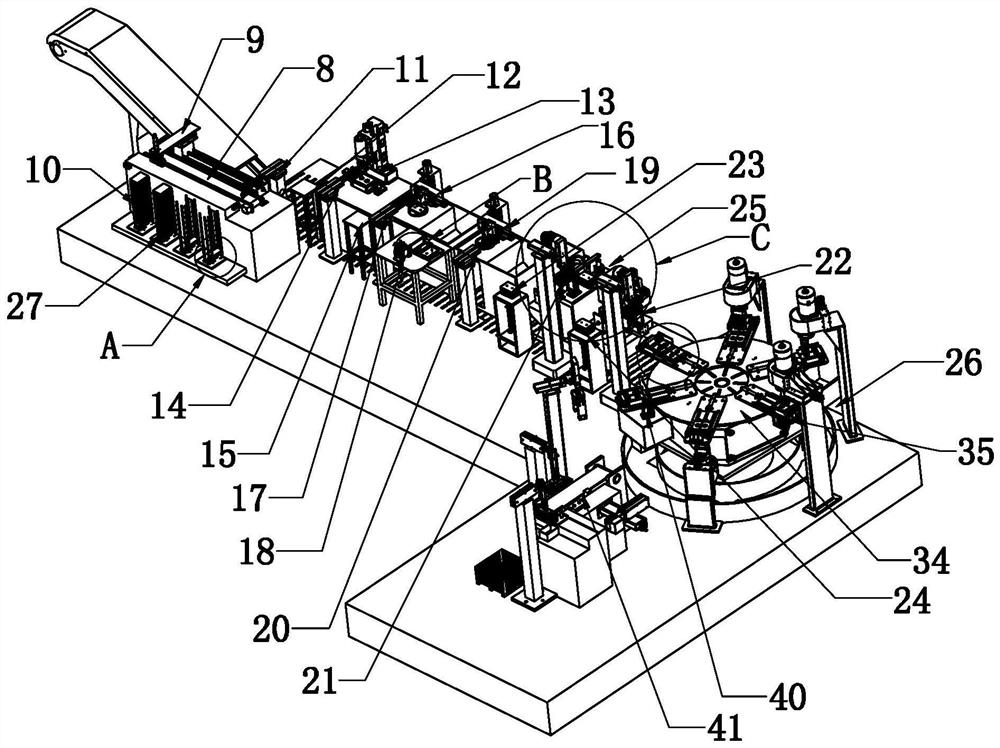

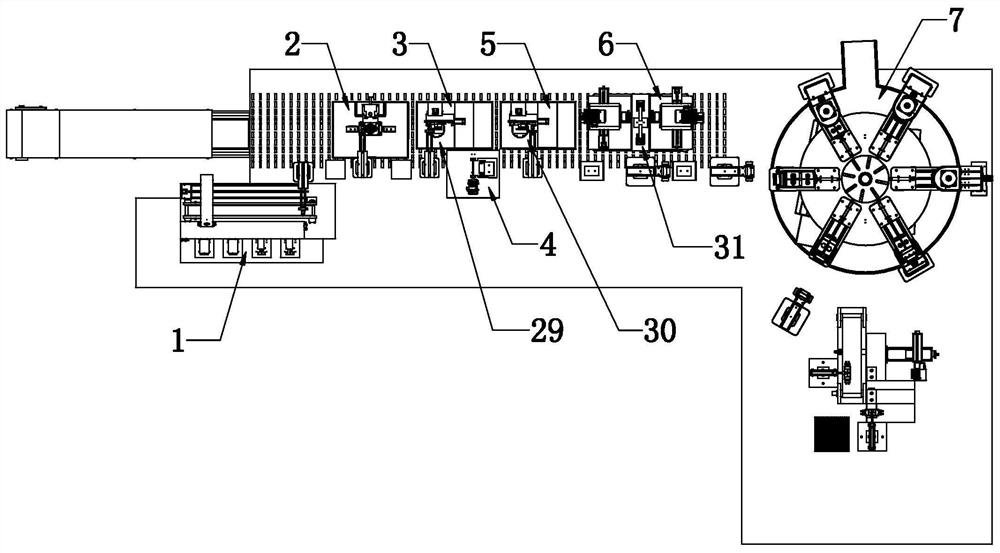

[0036] The present invention is to provide an automatic processing production line for plate parts for processing wear plates of this structure, which includes a feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com