Method for manufacturing dissimilar pipe joint by adopting bar stirring friction

A technology of friction stir and pipe joints, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of unstable dimensions, low welding efficiency, and low mechanical properties of joints, and reduce the risk of deformation or even bending. Improved production efficiency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

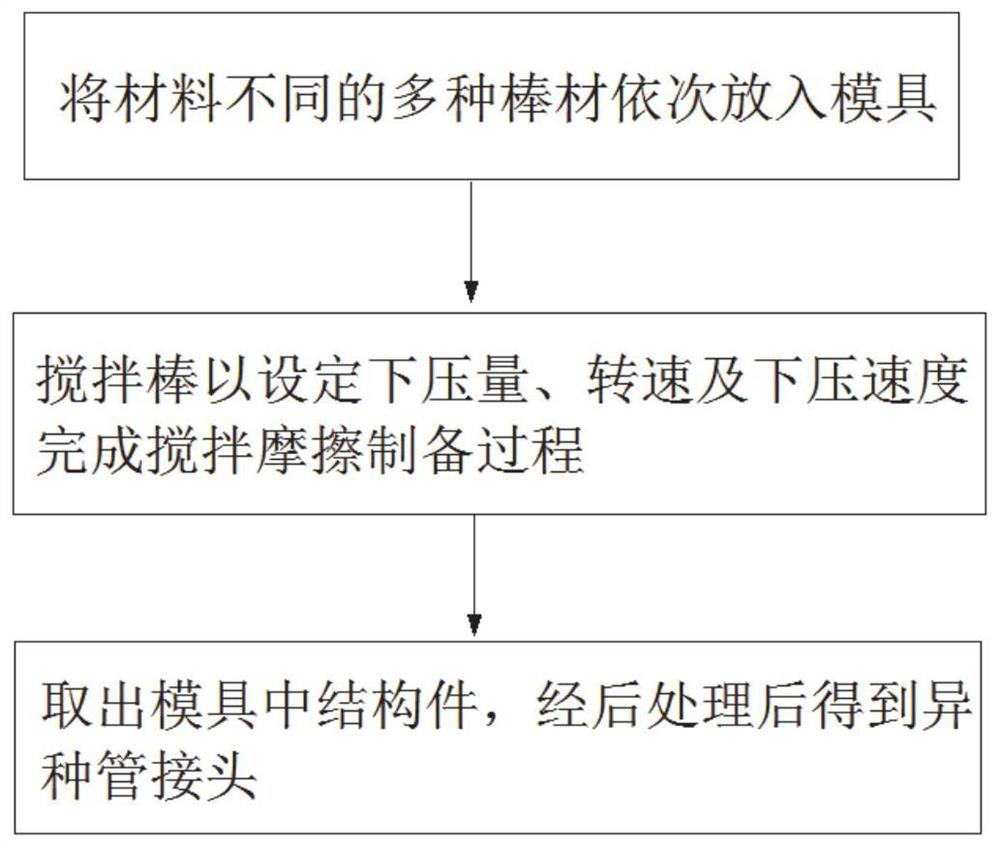

[0030] This embodiment provides a method for manufacturing dissimilar pipe joints using bar material friction stir, such as figure 1 shown, including:

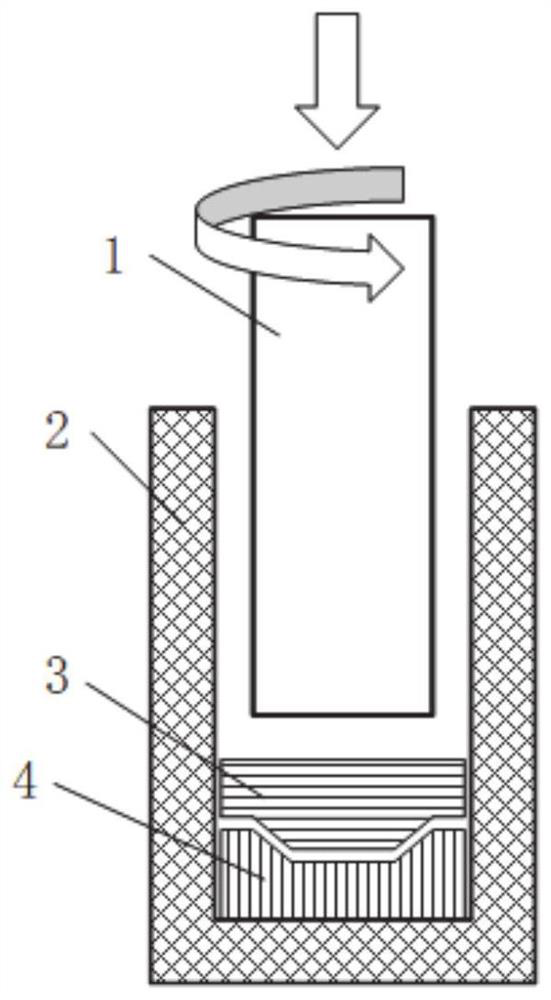

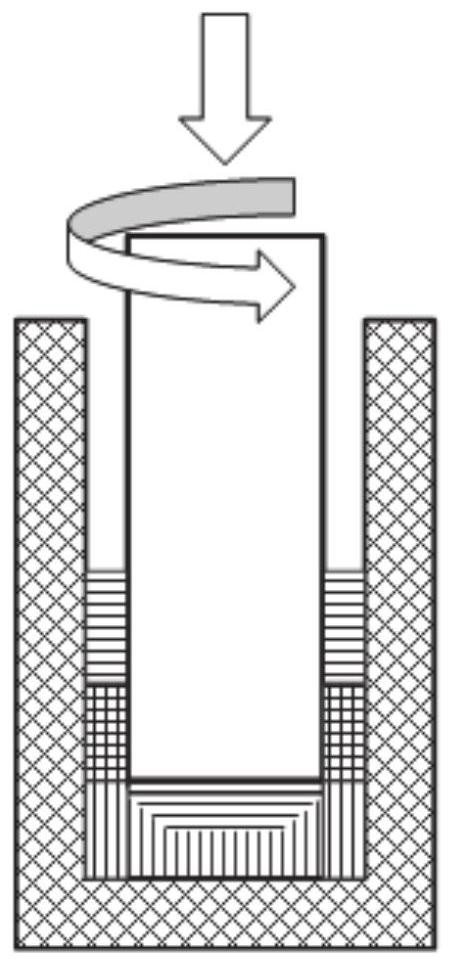

[0031] Put a variety of rods with different materials into the mold 2 in sequence, and the butt ends of the rods fit;

[0032] Stirring rod 1 completes the friction stirring preparation process by setting the pressing amount, rotating speed and pressing speed; under the rotation and stirring action of stirring rod 1, the material around stirring rod 1 produces plastic flow, and the material that undergoes plastic flow is limited in mold 2 In the annular cavity formed with the stirring rod 1, a structural member 5 is formed;

[0033] The structural part 5 in the mold 2 is taken out, and the heterogeneous pipe joint 6 is obtained after post-processing.

[0034] In this embodiment, the rods can be two or more metals or non-metallic materials, such as aluminum alloys, copper alloys, magnesium alloys, titanium alloys, composite m...

Embodiment 2

[0060] In this example, the method described in Example 1 is used to manufacture an aluminum / copper dissimilar alloy transition pipe joint with an outer diameter of 20 mm, an inner diameter of 14 mm, and a wall thickness of 3 mm, wherein the two materials are T2 copper alloy and 1050 aluminum alloy, specifically comprising the following steps:

[0061] Step 1: Preparation before the process:

[0062] Select a stainless steel mold and determine the inner diameter of the mold cavity Φ 1 20mm and cavity depth h 1 40mm, mold wall thickness h 2 is 5mm. The materials of dissimilar pipe fittings to be connected are T2 copper alloy and 1050 aluminum alloy respectively, and the wall thickness is h 3 3mm, the diameter of the stirring rod Φ 2 is 14mm.

[0063] Determine the rod material diameter Φ 3 19mm and material length L 1 9mm, determine the height (depth) L of the bar boss (groove) 2 2mm, the major diameter of the bar boss Φ 4 is 16mm, its minor diameter Φ 5 is 12mm; cor...

Embodiment 3

[0070] In this embodiment, the method described in Embodiment 1 is adopted. The transition pipe joint has a pipe wall thickness of 2 mm, an outer diameter of 30 mm, and an inner diameter of 26 mm for an aluminum / magnesium dissimilar alloy transition pipe joint, wherein the two materials are respectively 6061-T6 aluminum alloy And AZ31B-H24 magnesium alloy, the specific steps are as follows:

[0071] Step 1: Preparation before the process:

[0072] Select a stainless steel mold and determine the inner diameter of the mold cavity Φ 1 30mm and cavity depth h 1 60mm, mold wall thickness h 2 is 5mm. The materials of dissimilar pipe fittings to be connected are 6061-T6 aluminum alloy and AZ31B-H24 magnesium alloy respectively, with wall thickness h 3 2mm, the diameter of the stirring rod Φ 2 is 26mm.

[0073] Determine the rod material diameter Φ 3 29mm and material length L 1 9mm, determine the height (depth) L of the bar boss (groove) 2 3mm, the major diameter of the bar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com