Ni-plated steel sheet and method for manufacturing ni-plated steel sheet

A manufacturing method and technology for steel plates, which can be applied to manufacturing tools, chemical instruments and methods, furnaces, etc., can solve problems such as difficulty in providing, and achieve the effect of excellent Ni dissolution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The inventors of the present invention have studied the effects of various manufacturing conditions in order to improve the Ni elution resistance without impairing the formability of the Ni-plated steel sheet. As a result, it has been found that Ni elution resistance can be dramatically improved without impairing the formability of a Ni-plated steel sheet by making the energization pattern in the Ni electroplating step satisfy the requirements described below.

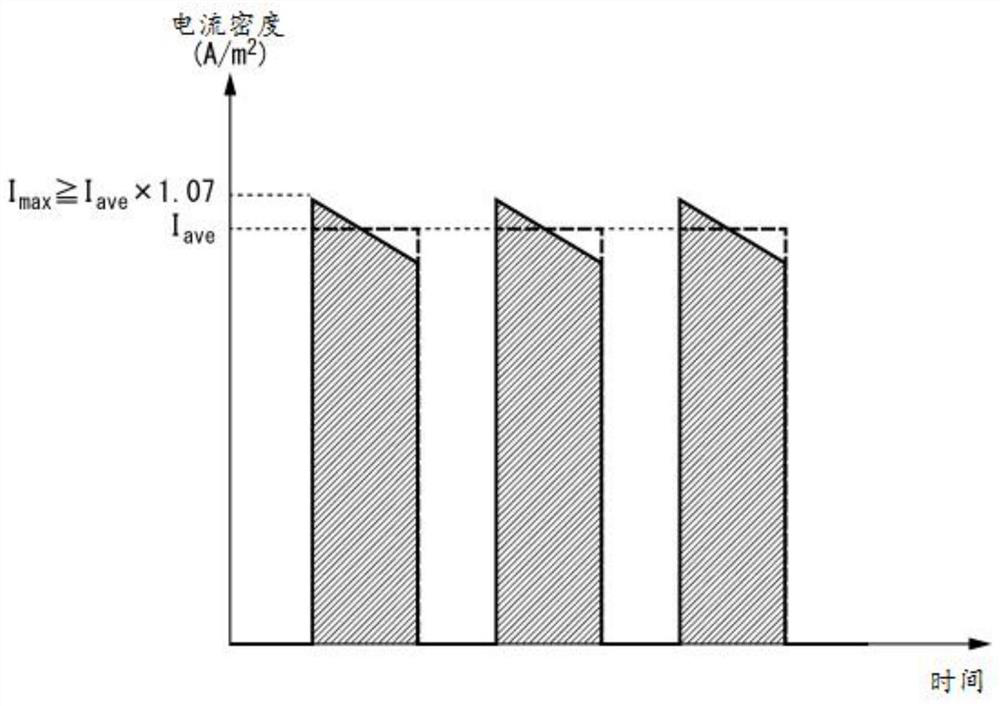

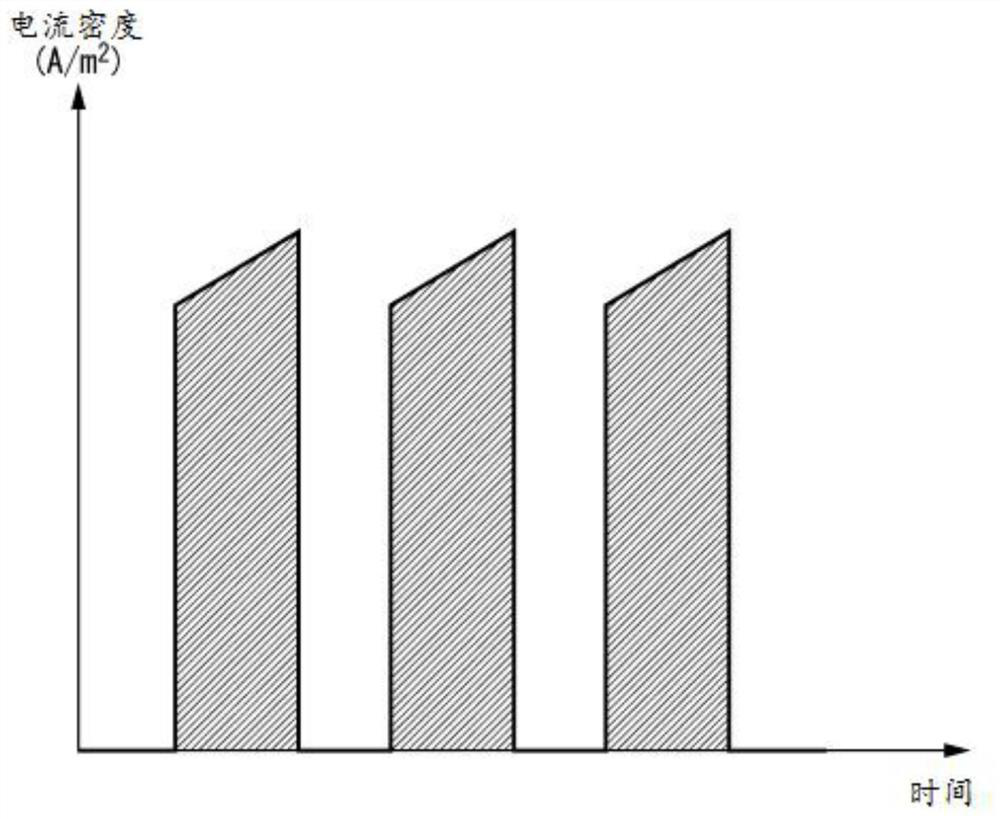

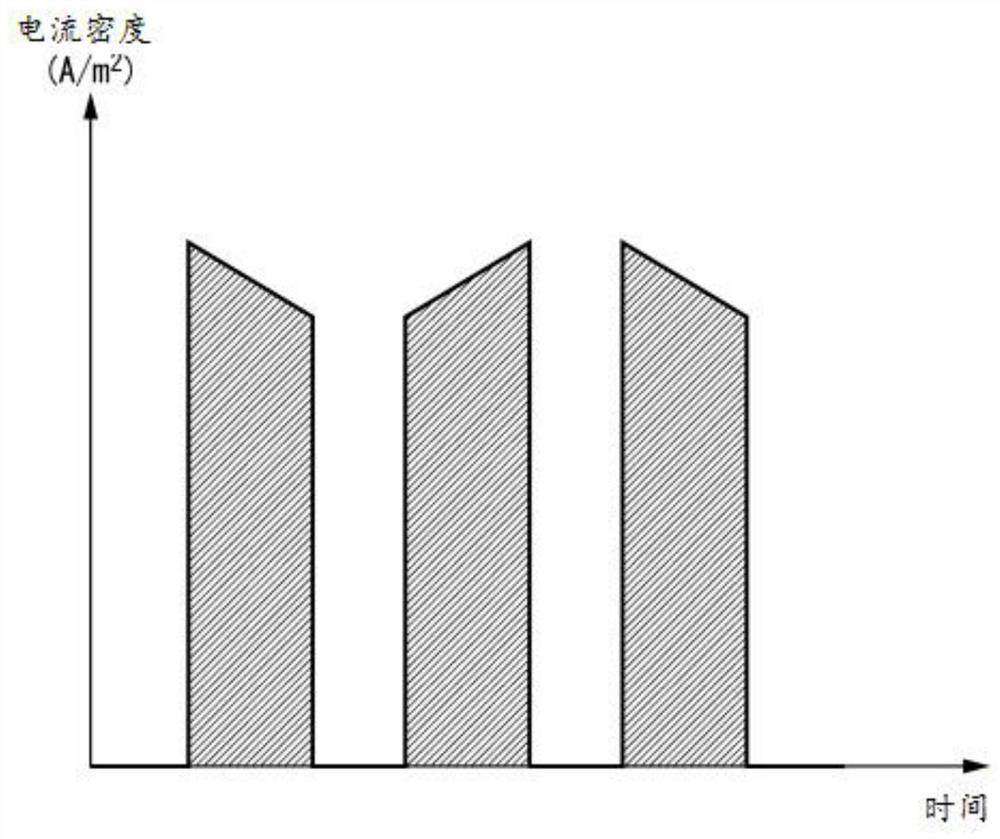

[0036] FIG. 1-1 is a schematic diagram showing an example of a current conduction pattern in a Ni plating process discovered by the present inventors, where the vertical axis represents current density and the horizontal axis represents time. This energization pattern satisfies the following requirements. In addition, making the current density not constant means that the current density is not set at a constant value during the energization period, as shown in FIG. 1-1 and the like.

[0037] (1) Three or more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com