Electrode member, pole piece, and manufacturing method thereof and battery

A component and electrode technology, applied in the field of batteries, can solve the problems of occupying space, increasing weight and cost, and achieve the effects of reducing production costs, ensuring flow capacity, and better bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to reduce the consumption of metals, control cost, etc., at present, some metal foil collectors are selected to replace a composite collector.

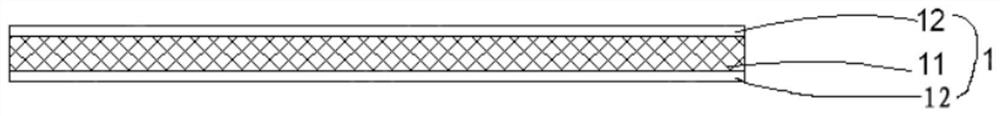

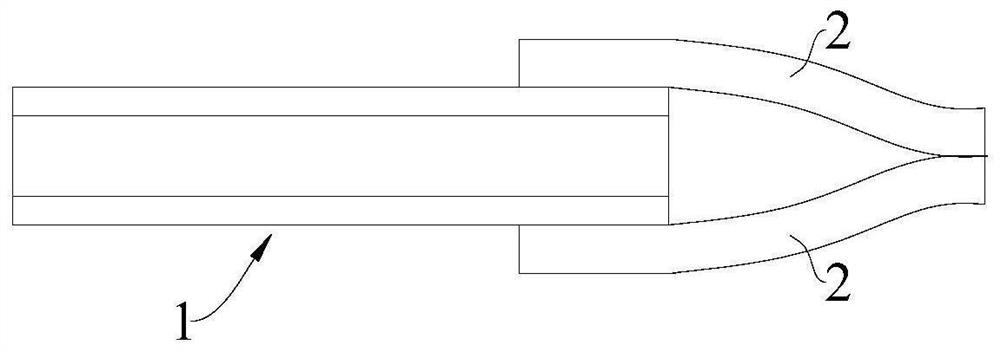

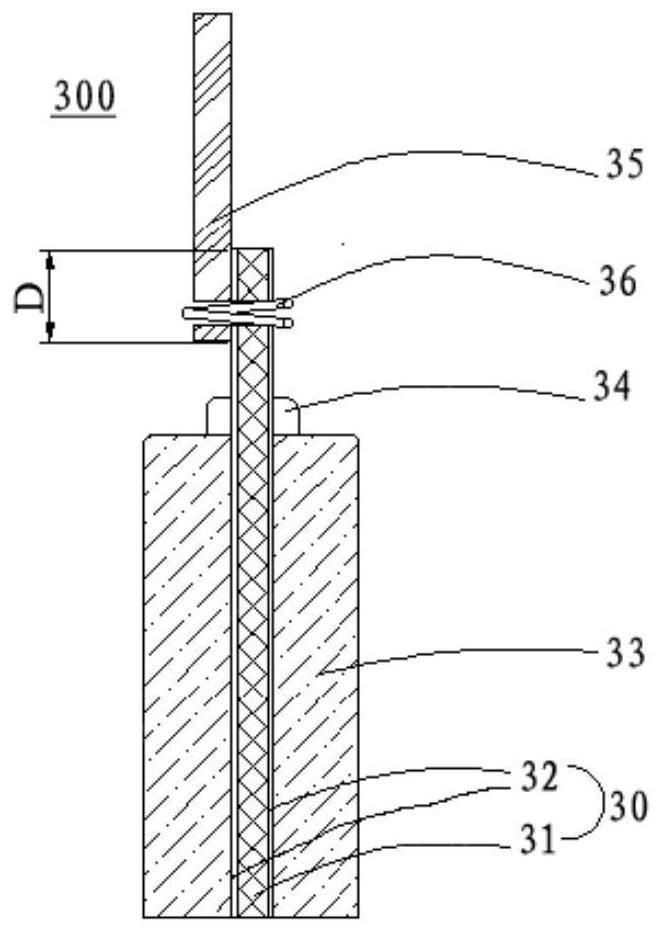

[0041] Such a composite collector is usually constructed in a "sandwich" structure. The composite current collector is a multi-layer composite structure that binds to a polymer film and metal. See figure 1 The composite collector 1 includes a layer of polymer thin film 11, and two metal layers 12 of both sides of its thickness direction.

[0042] The composite collector 1 described above reduces the amount of metal material compared to the collector of the metal foil structure, so that high costs caused by a large amount of metal can be reduced. However, there are some problems in such a composite collector. For example, since the amount of metal material is reduced, and the two metal layer 12 is separated by the middle polymer film 11 in the middle, and the current of the two-layer metal layer 12 in the composite collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com