Exposure and development method of metal box dam, metal box dam and ceramic substrate

A metal dam, exposure and development technology, used in microlithography exposure equipment, photolithographic process exposure devices, electrical components, etc., can solve the problem of conforming to standards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

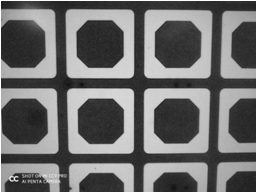

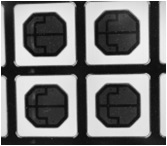

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments without creative efforts by those skilled in the art fall within the protection scope of the present invention.

[0042] The dam parameters targeted by the present invention are as follows: front copper structure: 65+450+200, bottom copper structure: 65+30, standard total thickness: 1310 μm; each PNL (120*120mm)=2set=2*377pcs.

[0043] Such as Figure 3-5 As shown, after adjusting the parameters of exposure and development in the present invention, there is no exposure failure, slight side erosion, acceptable, and the appearance is ok. These adjustments are not taught in the prior art, and making these adjustments requires cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com