Gas pressure test system for pneumatic tension compensators

A gas pressure and testing system technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of poor compensation effect, high installation accuracy requirements, low yield, etc., to reduce the impact of flickering light and improve test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The gas pressure testing system for the pneumatic tension compensator provided by the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0034] like figure 1 As shown, the gas pressure testing system for the pneumatic tension compensator provided by the present invention includes a gas pressure sensor, a signal processing circuit, an image sensor, an image acquisition setting unit, a storage unit, a data transmission communication unit, a comparison unit and an alarm unit.

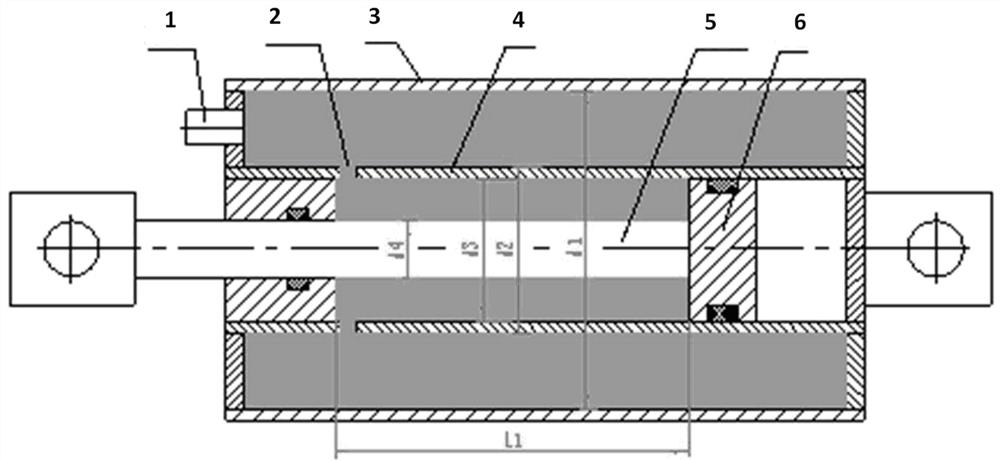

[0035] like figure 2 As shown, the pneumatic tension compensator includes an inflation valve 1, a ventilation hole 2, an air storage cylinder 3, a cylinder tube 4, a piston rod 5 and a piston 6. The inflation valve 1 is connected with the air storage cylinder 3, and the air storage cylinder 3 is connected to the cylinder through the ventilation hole 2. The cylinder 4 is connected, the piston 6 is arranged at one end of the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com