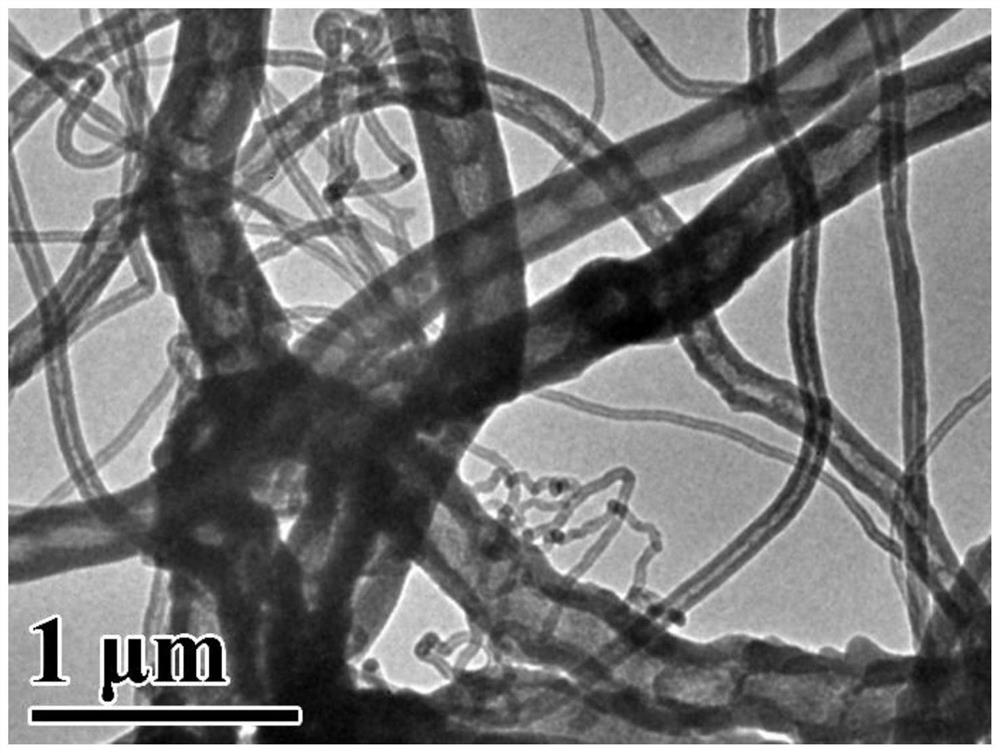

A kind of carbon nanotube composite material with hierarchical structure and its preparation method

A technology of carbon nanotubes and hierarchical structure, which is applied in the field of carbon nanotube composite materials with hierarchical structure and its preparation, to achieve high capacitance retention rate, shortened charge transfer distance, and good uniformity of tube diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0043] Step 1: Preparation of Catalyst

[0044] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 600 °C for 2 h, and then in H 2 Continue calcination at the same temperature for 35 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The gas flows of Ar and Ar are 100mL / min and 300~330mL / min respectively, and the H 2 The flow rate of Ar a...

Embodiment 2

[0062] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0063] Step 1: Preparation of Catalyst

[0064] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 620 °C for 2 h, and then heated in H 2 Continue calcination at the same temperature for 40 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The gas flows of Ar and Ar are 110mL / min and 330mL / min respectively;

[0065] Step 2: Preparation o...

Embodiment 3

[0070] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0071] Step 1: Preparation of Catalyst

[0072] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 600 °C for 2 h, and then in H 2 Continue calcination at the same temperature for 30 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The flow rates of Ar and Ar are 120mL / min and 360mL / min respectively;

[0073] Step 2: Preparation of Hier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com