Building element

A technology of building components and steel mesh, applied in building components, buildings, building structures, etc., can solve the problem that the number and size of through holes are not further expressed, and achieve the effect of high bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

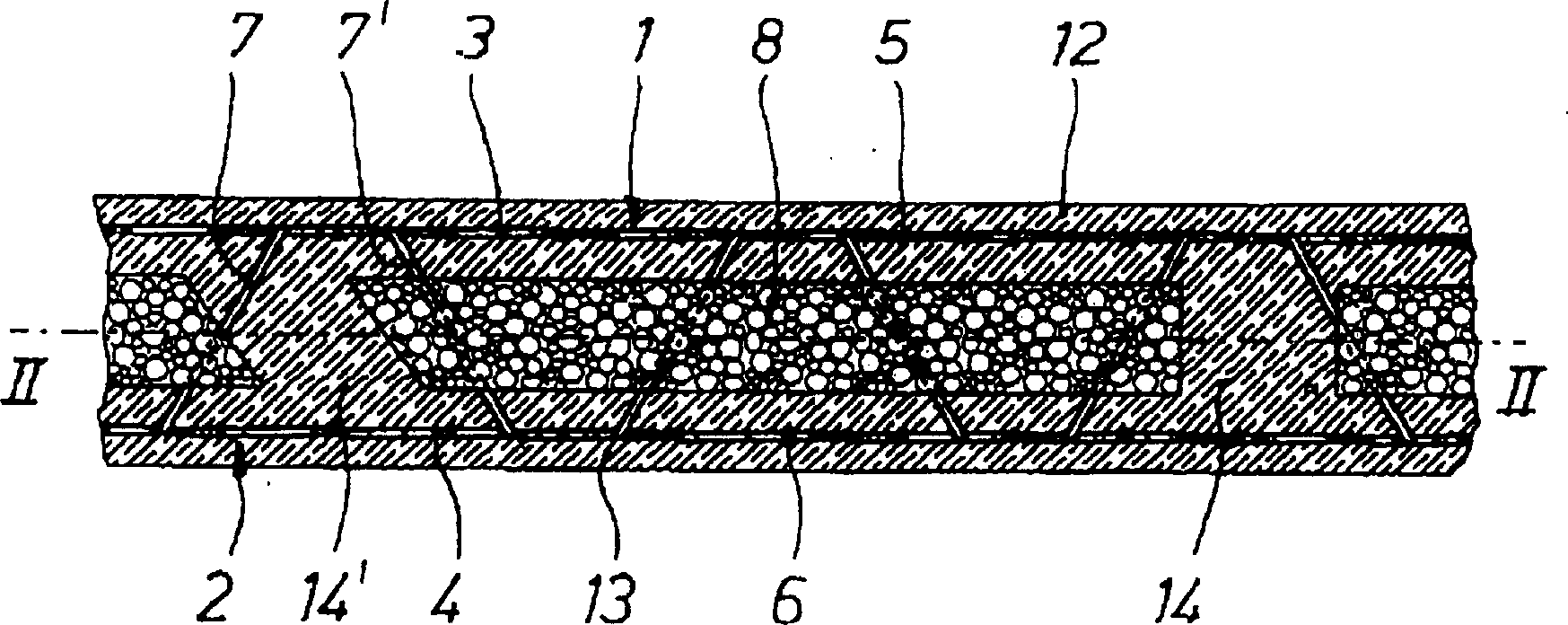

[0019] The building element of the present invention shown in the partial view of FIG. 1 and the sectional view along line II-II of FIG. 2 is composed of an outer steel mesh 1 and an inner steel mesh 2 arranged in parallel at predetermined intervals. Each reinforcement mesh 1 and 2 is composed of a plurality of longitudinal reinforcement bars 3 and 4 and a plurality of transverse reinforcement bars 5 and 6, and these reinforcement bars intersect each other and are welded together at intersection points. The mutual spacing of the longitudinal reinforcing bars 3, 4 and the mutual spacing of the transverse reinforcing bars 5, 6 are selected according to the static requirements of the building element and for example the spacing is from 50 to 150 mm, wherein according to the invention the spacings can be of equal or different size, The diameter of the longitudinal and transverse reinforcement 3 , 4 and 5 , 6 is also selected according to the static requirements and preferably range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com