Ship camera support

A camera and ship technology, applied in the direction of machines/brackets, ship parts, supporting machines, etc., can solve problems such as insufficient structural and functional design, poor installation and shooting effects, inconvenient multi-angle adjustment and shooting needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

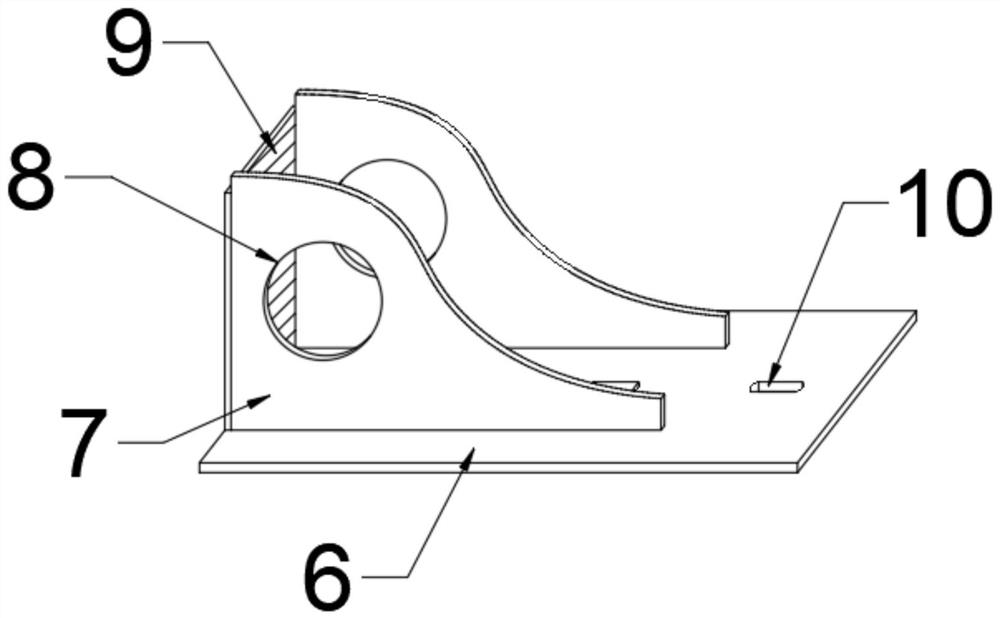

[0015] When the present invention is specifically implemented, a ship camera bracket includes a bracket base 1, a vertical bar 2, a cross bar connection part 3, a cross bar 4, a camera base 5, a bottom plate 6, a side plate 7, a round hole 8, and a rear plate 9 , opening 10, fixing bolt 11, it is characterized in that: the lower end of the vertical bar 2 is connected with the bracket base 1 by a screw, the upper end is connected and fixed with the horizontal bar connection part 3 of the horizontal bar 4 by a screw, and the end of the horizontal bar 4 The camera base 5 is socketed, and the camera base 5 includes a bottom plate 6, two side plates 7 are symmetrically welded on the bottom plate 6, and a round hole 8 is drilled on the side plate 7, and the rear walls of the two side plates 7 are A rear plate 9 is welded, and a fixing bolt 11 is connected to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com