820mpa class large thickness ship steel plate and its manufacturing method

An 820mpa, large-thickness technology, applied in the direction of manufacturing tools, temperature control, metal rolling, etc., can solve the problems of lack of experience in polar ship design and manufacturing, and achieve high control of shape and grain size, and uniform refinement of phase transformation structure , the effect of refining the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments are described below in conjunction with the accompanying drawings:

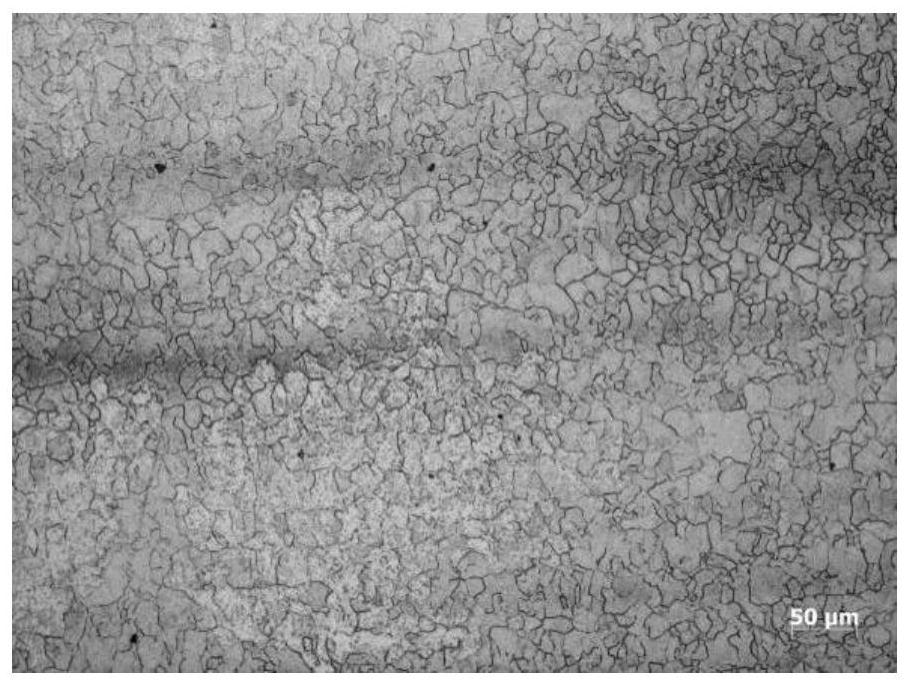

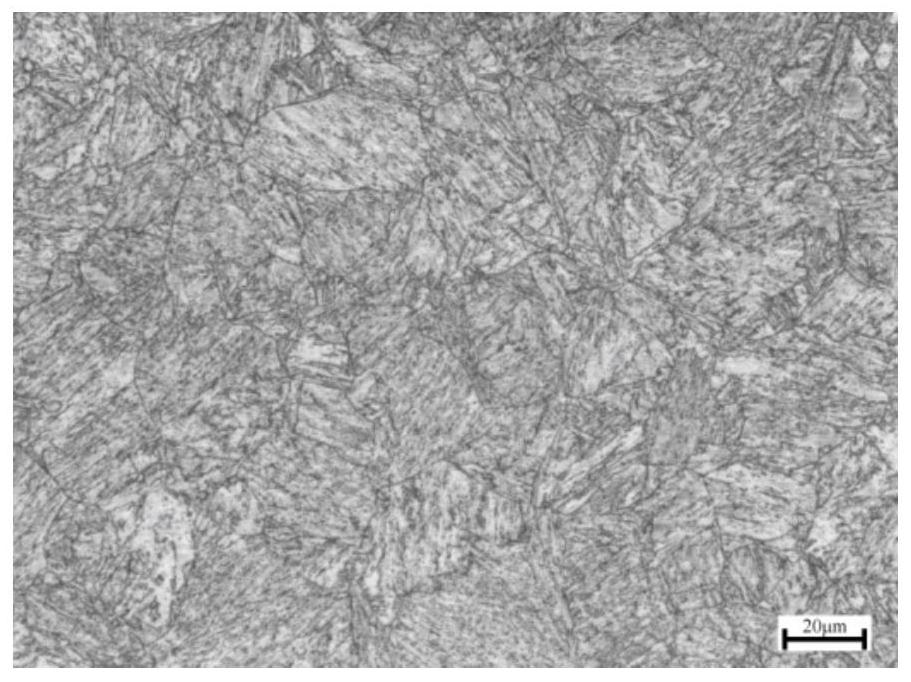

[0038] It can be seen from the metallographic structure of Example 1 that after two isothermal quenching + tempering processes, the structure of the steel plate is basically tempered sorbite, the grain boundaries are clear, and the grains are very small. After the secondary quenching, the grains of the steel sheet are further refined, thereby greatly improving the low temperature toughness of the steel sheet at the tensile strength level.

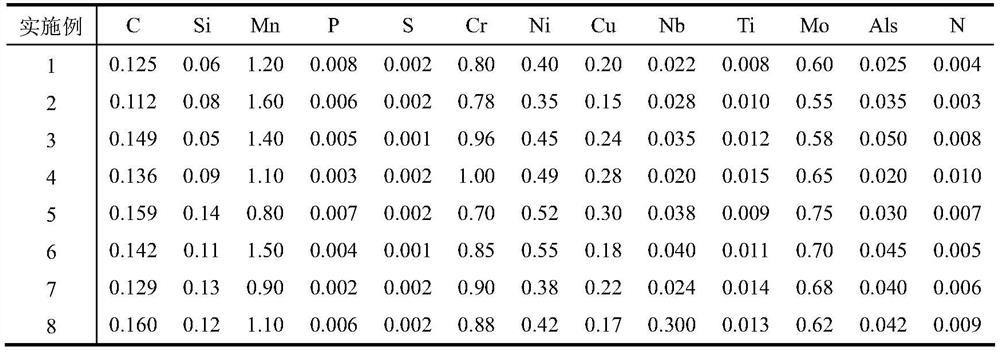

[0039] The chemical composition of the steel sheet for ships with a tensile strength of 820MPa, low temperature resistance, ultra-high strength, and thickness of the present invention is shown in Table 1. The tensile and impact properties are shown in Table 4.

[0040] Table 1 Chemical composition of steel according to the embodiment of the present invention

[0041]

[0042] Table 2 Smelting process of the embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com