Complex microbial inoculant for camel milk fermentation as well as preparation method and application thereof

A compound bacterial agent and fermentation method technology, which is applied in microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc. , not suitable for fermented camel milk and other problems, to achieve the effect of good storage stability, high number of viable bacteria and mild sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

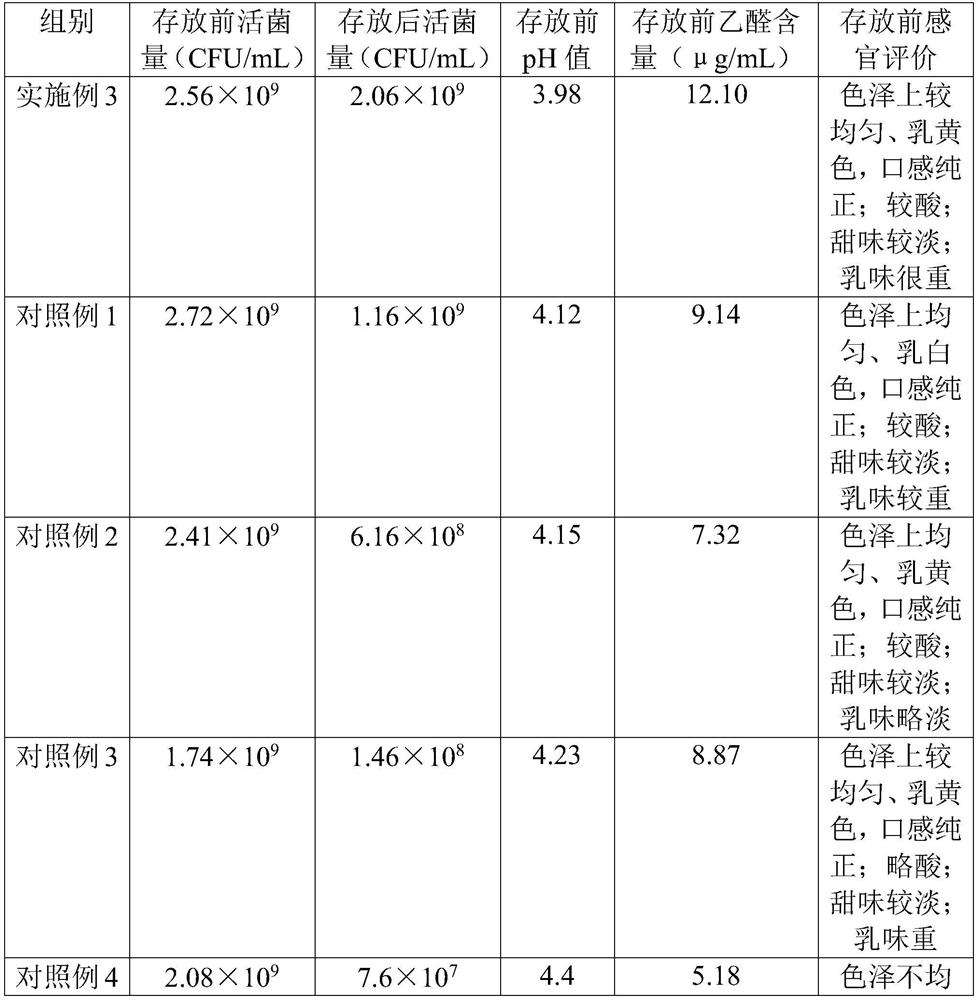

Examples

Embodiment 1

[0044] 1. Compound microbial agent for camel milk fermentation

[0045] The above-mentioned composite bacterial agent for camel milk fermentation includes the following strains:

[0046] 4 parts of Lactobacillus plantarum K25, 2 parts of Lactobacillus plantarum KC28, 3 parts of Lactobacillus plantarum D1501, 1.5 parts of Leuconostoc mesentericus SHU1396;

[0047] 2. Preparation method

[0048] The above-mentioned preparation method of the compound bacterial agent for camel milk fermentation, the preparation method comprises the following steps:

[0049] (a) According to 1.5×10 12 Inoculum amount of CFU / L Inoculate each strain into the culture medium and culture at 37°C for 24 hours, centrifuge to obtain the sludge of each strain, wherein,

[0050] The culture medium comprises the following components in weight percentage:

[0051]5% carbon source, 3% nitrogen source, 12% proliferation factor, disodium hydrogen phosphate and potassium dihydrogen phosphate, the balance is UM...

Embodiment 2

[0068] 1. Compound microbial agent for camel milk fermentation

[0069] The above-mentioned composite bacterial agent for camel milk fermentation includes the following strains:

[0070] 6 parts of Lactobacillus plantarum K25, 4 parts of Lactobacillus plantarum KC28, 1 part of Lactobacillus plantarum D1501, 0.5 part of Leuconostoc mesentericus SHU1396;

[0071] 2. Preparation method

[0072] The above-mentioned preparation method of the compound bacterial agent for camel milk fermentation, the preparation method comprises the following steps:

[0073] (a) According to 1.2×10 12 Inoculum amount of CFU / L Inoculate each strain into the culture medium and culture at 37°C for 24 hours, centrifuge to obtain the sludge of each strain, wherein,

[0074] The culture medium comprises the following components in weight percentage:

[0075] Carbon source 3%, nitrogen source 5%, proliferation factor 6%, disodium hydrogen phosphate and potassium dihydrogen phosphate, the balance is UMRS...

Embodiment 3

[0092] 1. Compound microbial agent for camel milk fermentation

[0093] The above-mentioned composite bacterial agent for camel milk fermentation includes the following strains:

[0094] 5 parts of Lactobacillus plantarum K25, 3 parts of Lactobacillus plantarum KC28, 2 parts of Lactobacillus plantarum D1501, 1 part of Leuconostoc mesentericus SHU1396;

[0095] 2. Preparation method

[0096] The above-mentioned preparation method of the compound bacterial agent for camel milk fermentation, the preparation method comprises the following steps:

[0097] (a) According to 1.3×10 12 Inoculum amount of CFU / L Inoculate each strain into the culture medium and culture at 37°C for 24 hours, centrifuge to obtain the sludge of each strain, wherein,

[0098] The culture medium comprises the following components in weight percentage:

[0099] 4% carbon source, 4% nitrogen source, 10% proliferation factor, disodium hydrogen phosphate and potassium dihydrogen phosphate, the balance is UMRS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com