A high-efficiency colloid mill for dairy processing

A high-efficiency, dairy product technology, applied in the field of dairy product processing, can solve the problems of difficulty in adjusting the distance between the first fixed tooth and the rotating tooth, and inconvenience in processing products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

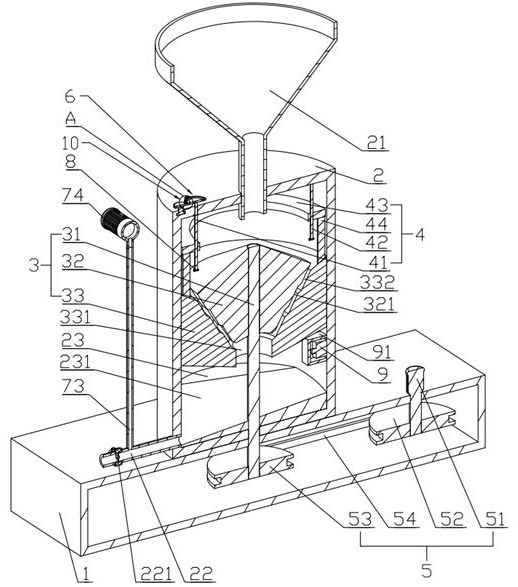

[0035] The present invention will be further described in detail below with reference to the accompanying drawings.

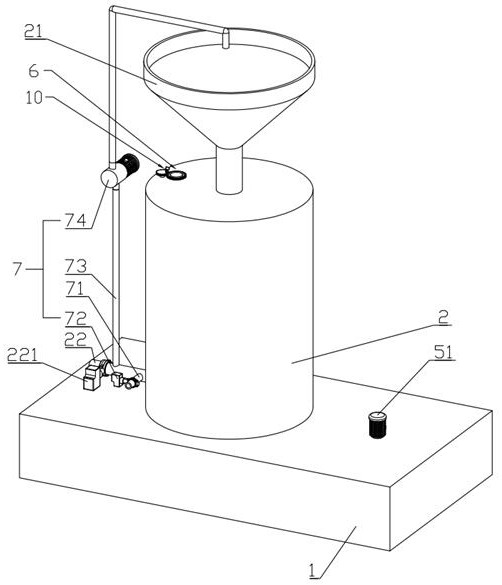

[0036] like Figure 1-4 As shown, a high-efficiency colloid mill for dairy product processing includes a base 1, a box body 2, a feeding hopper 21, a grinding component 3, an adjustment component 4, a lower driving component 5, a discharge pipe 22, and an upper driving component 6. and detection of reworked components 7 . The base 1 is a hollow cuboid structure, the box body 2 is a hollow cylindrical structure, the axis of the box body 2 is vertical, and the bottom surface of the box body 2 is fixed to the upper surface of the base 1 . The feeding hopper 21 is a funnel-shaped structure with a vertical axis, and its upper opening diameter is larger than the lower opening diameter of the feeding hopper 21 .

[0037] The grinding assembly 3 is installed in the box body 2 , and the grinding assembly 3 includes a rotating rod 31 , a rotating tooth 32 and a fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com