Device and method for measuring thickness and refractive index of thin film

A technology of film thickness and refractive index, which is applied in the field of optical measurement, can solve the problems of difficult film angle, difficult operation, and low measurement accuracy, and achieve the effect of convenient and simple measurement process, high-precision measurement of film thickness, and elimination of disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

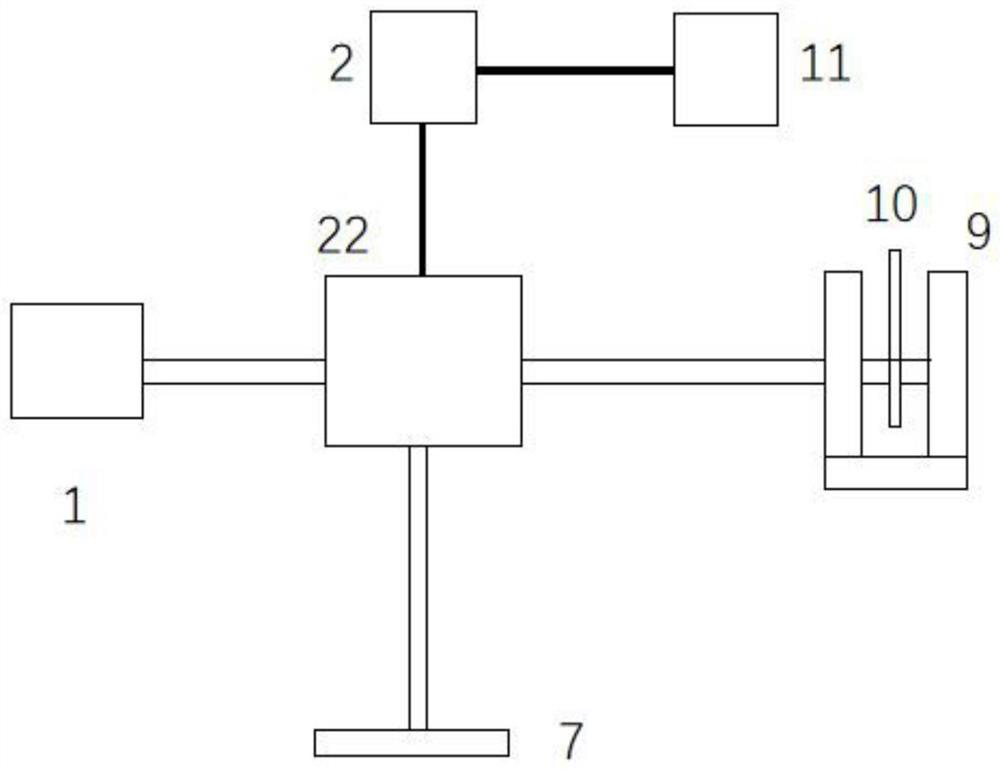

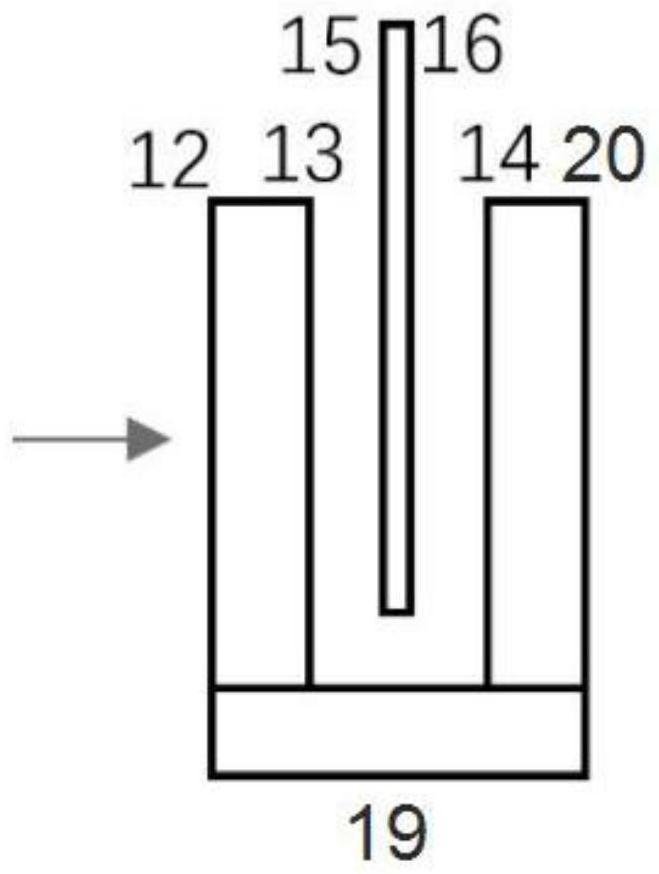

[0148] According to a specific embodiment of the present invention, in combination with the Figure 1-11 , the device and method for measuring the thickness and refractive index of thin films of the present invention will be described in detail. The thickness of the sample used in this embodiment is 10 microns, the coupler is a 2*1 fiber coupler, and the first light splitting element is a beam splitting prism. The method of the present invention identifies the film as a thin film.

[0149] The invention provides a device for measuring film thickness and refractive index, comprising:

[0150] Low coherence light source, 2*1 fiber coupler, collimator, beam splitter prism, first lens, second lens, mirror, sample slot, spectrometer and signal processing unit;

[0151] The low-coherence light source and the spectrometer are connected to a 2*1 fiber coupler through an optical fiber, and the 2*1 optical fiber coupler is connected to a collimator through an optical fiber; the spectro...

Embodiment 2

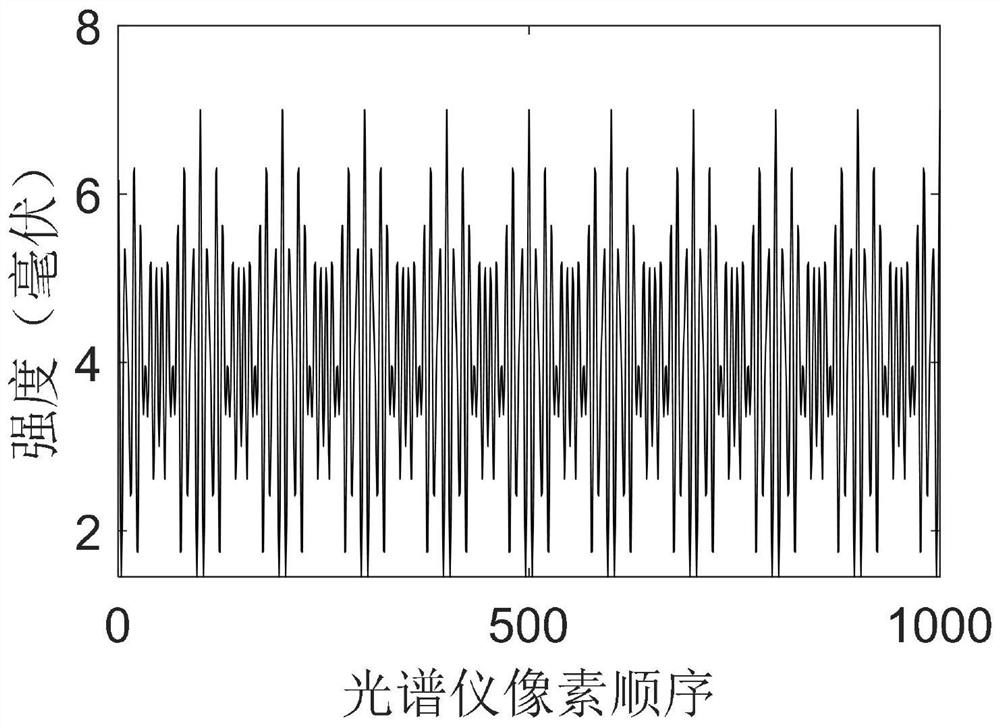

[0190] According to a specific embodiment of the present invention, in combination with the Figure 1-11 , the method for measuring the thickness and refractive index of a thick film of the present invention is described in detail. The thickness of the sample is 50 microns and the refractive index is 1.2. According to the method of the present invention, the film is determined to be a thick film.

[0191] This embodiment adopts the device for measuring the thickness and refractive index of the film in the first embodiment, and other different embodiments of the device of the present invention can also be used, and the measurement methods are all the same.

[0192] The present invention provides a method for measuring film thickness and refractive index, using the above-mentioned device for measuring film thickness and refractive index, comprising the following steps:

[0193] When there is no sample to be tested in the sample tank 9, when the sample tank 9 is empty, the optica...

Embodiment 3

[0213] According to another specific embodiment of the device of the present invention, the device for measuring the film thickness and the refractive index of the present invention can also be Figure 10 to implement. The first spectroscopic element adopts a spectroscopic prism, and a spectroscopic element that can achieve the same function, such as a spectroscopic sheet, can also be used instead.

[0214] The present invention provides a device for measuring film thickness and refractive index, comprising: a low-coherence light source 1, a spectrometer 2, an optical fiber coupler 3, a reflector 7, a beam splitting prism 5, a sample slot 9, a signal processing unit 11, and a third lens 21; the optical fiber coupler 3 is a 2*1 optical fiber coupler, and other couplers can also be used, at least a 2*1 coupler.

[0215] The low-coherence light source 1 and the spectrometer 2 are connected to the fiber coupler 3 through an optical fiber;

[0216] The spectrometer 2 is electrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com