Garbage sorting device for household garbage pyrolysis

A garbage sorting and domestic garbage technology, applied in packaging, wet separation, solid separation, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effects of improved quality, stable operation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

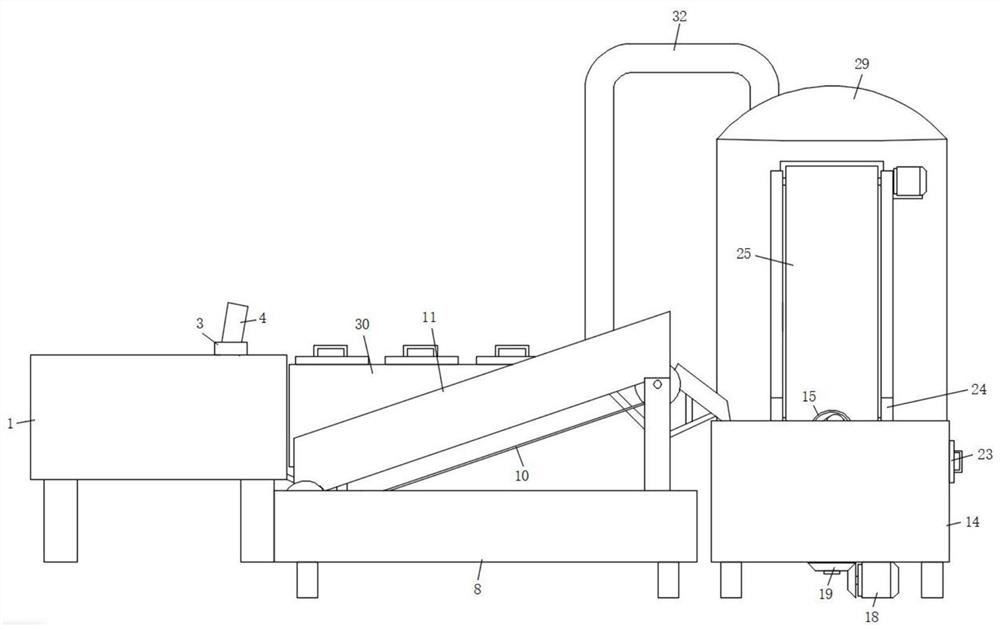

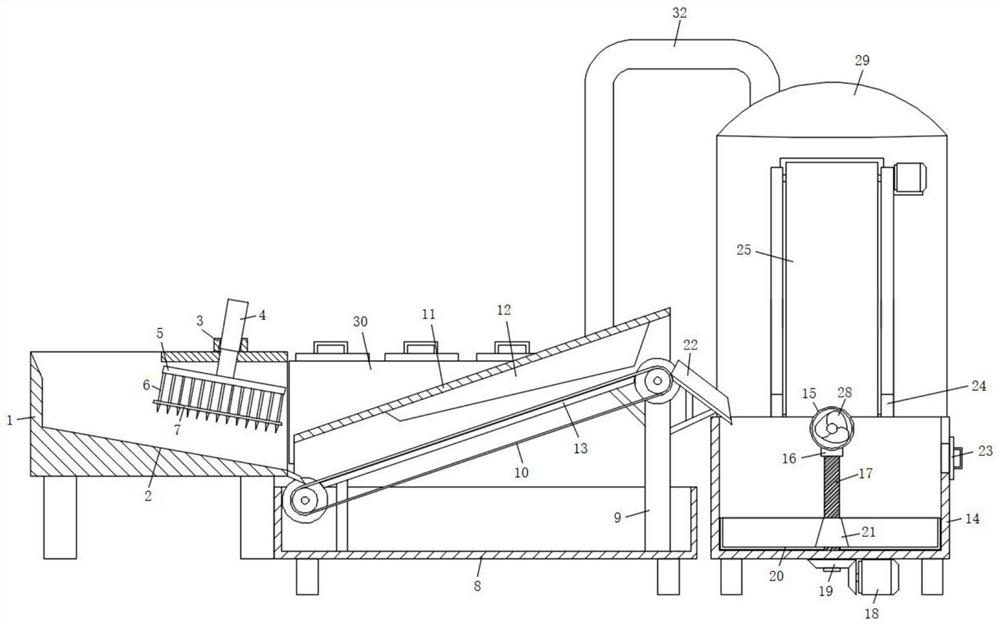

[0033] refer to Figure 1-6 , a garbage sorting device for pyrolysis of domestic waste, comprising a feeding vessel 1, a lowering trough 2 is provided on the bottom surface of the lowering vessel 1, and an installation bar 3 is welded on the top surface of the lowering vessel 1, and the front and rear sides of the installation bar 3 are Mounting holes are opened on both sides, and the inner walls of the mounting holes are fixed with electric telescopic rods 4 through screws. The output end of the electric telescopic rods 4 is fixed with a puncture plate 5 through screws, and the bottom surface of the puncture plate 5 is fixed with a puncture rod 6 through screws. , the inner wall of the front and rear sides of the feeding dish 1 is also fixed with a limit plate 7, and the top surface of the limit plate 7 is provided with a through hole, and the piercing rods 6 are all slidably connected in the through hole, and are driven by the electric telescopic rod 4 when feeding domestic was...

Embodiment 2

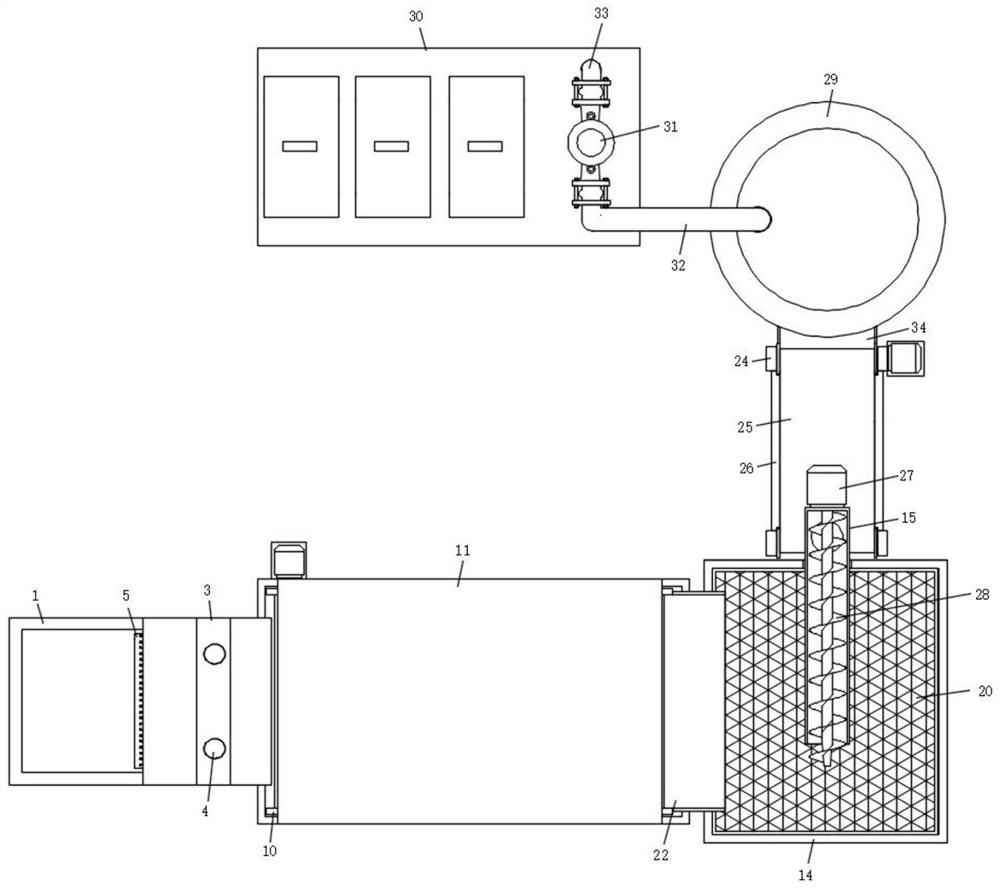

[0035] like figure 1 , 2 , 3 and 6, the present embodiment is basically the same as Embodiment 1. Preferably, the inner wall of the gas purification box 30 is glued and fixed with a partition 302, and the three partitions 302 divide the gas purification box 30 into a clean room 303, Clean room 2 304, clean room 3 305 and water storage room 306, clean room 1 303, clean room 2 304 and clean room 3 305 are fixed with partition screens 307 on both sides of the lower end, clean room 1 303, clean room 2 304 and The third clean room 305 is close to the water storage room 306, and the inner wall of one side is fixed with a hollow dish 308. The side of the hollow dish 308 close to the water storage room 306 and the partition plate 302 are connected with the second air duct 309, and the first clean room 303, Clean room 2 304 and clean room 3 305 are equipped with refueling holes on the top side, and the inner walls of the refueling holes are provided with sealing plugs 2 310, and the i...

Embodiment 3

[0039] like figure 2 As shown, this embodiment is basically the same as that of Embodiment 1. Preferably, the feeding chute 2 is inclined downward from the side of the feeding container 1 to the side of the leachate collecting container 8, and the puncture plate 5 and the limiting plate 7 are all connected to the leachate collection container 8. The bottom surfaces of the feeding chute 2 are arranged in parallel.

[0040] In this embodiment, the unloading chute 2 is provided with an inclination, so that domestic waste can smoothly slide down in the unloading dish 1 to realize the autonomous feeding operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com