Electrothermal film

An electric heating film and heating core technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of reduced high temperature life in the middle, overheating and burning of the central part, etc., to prolong the service life and prevent local temperature. The effect of too high and small power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

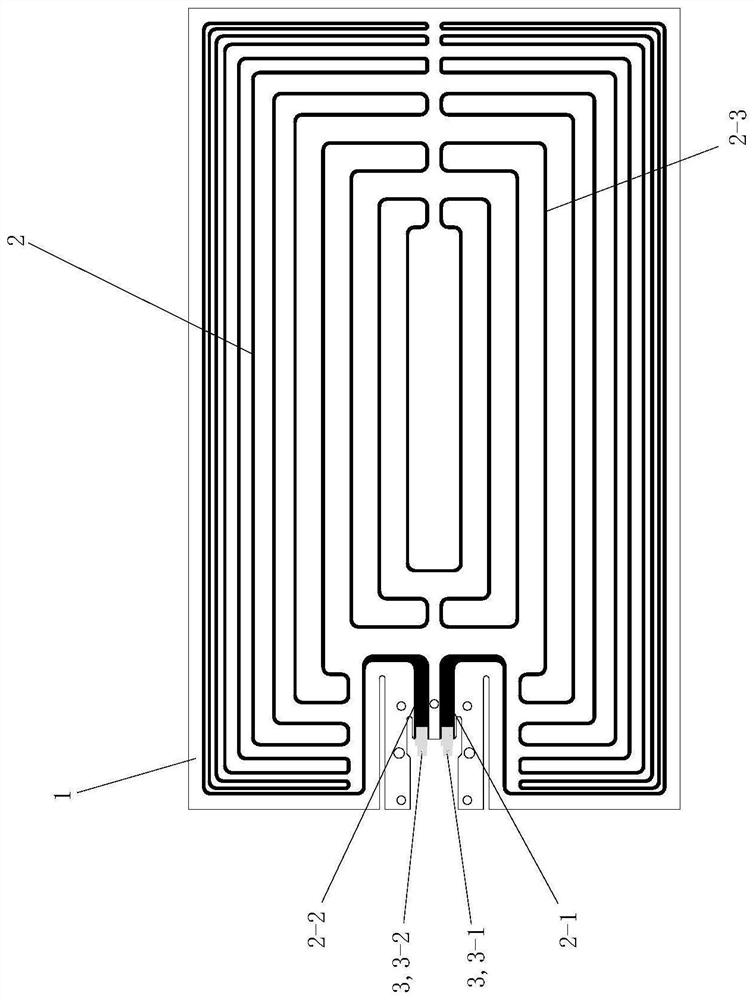

[0030] See figure 1 , The electrothermal film in this embodiment 1 includes an outer cladding layer 1 , a heating core layer 2 and an electrical connection sheet assembly 3 .

[0031] The coating outer layer 1 is composed of an upper surface layer and a bottom layer, both of which are made of PET (PET is the abbreviation of Polyethyleneterephthalate in English, referred to as PET or PETP) or PI (PI is the abbreviation of Polyimide in English, PI is commonly known as polyimide in Chinese, It is made of aromatic heterocyclic polymer compound with imide group chain link in molecular structure) or epoxy resin material. When polyimide is used, it has better high temperature resistance and is suitable for occasions with high fire protection requirements. use. Corresponding parts of the upper surface layer are fixed on the bottom layer and the heating core layer 2 through hot-melt adhesive thermocompression bonding from top to bottom. The heating core layer 2 is wrapped between the...

Embodiment 2

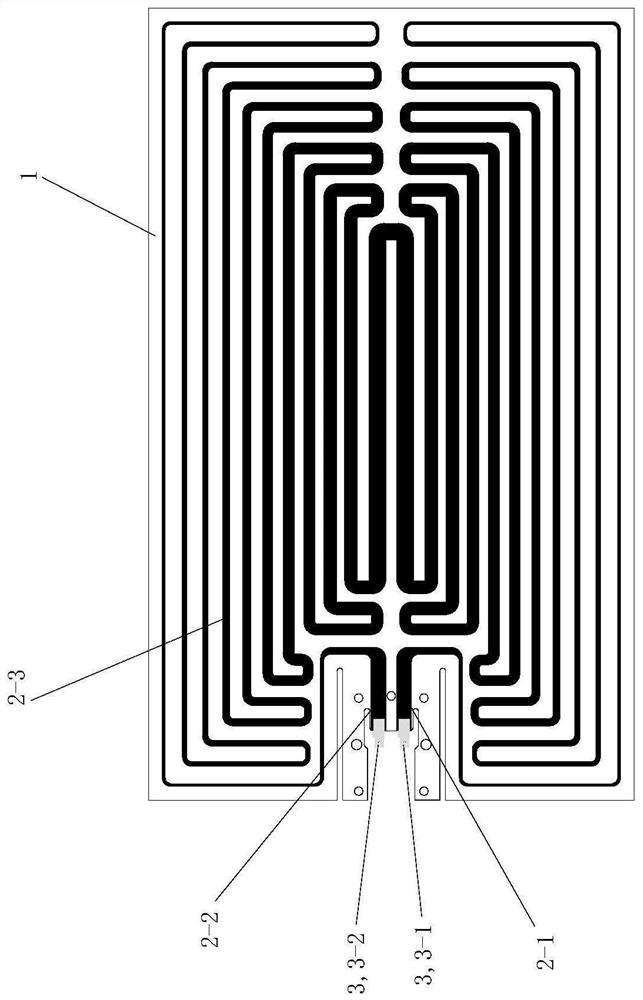

[0036] See figure 2 , the rest of this embodiment is the same as Embodiment 1, the difference is that: the conductive cross-sectional area of the heating part 2-3 is gradually reduced from the inside to the outside, and according to the formula P=I²R, the current in series is the same, and the metal strip per unit length The smaller the conductive cross-sectional area, the greater the resistance and the greater the power. The distance between the parallel adjacent parts of the heating part 2-3 is gradually increased from the inside to the outside. According to the temperature difference between the periphery and the center of the electrothermal film in the working state, it is determined that the periphery needs to be increased and the central part needs to be reduced. The heating power can make the surface temperature of the electrothermal film more balanced under the condition that the overall power remains unchanged.

Embodiment 3

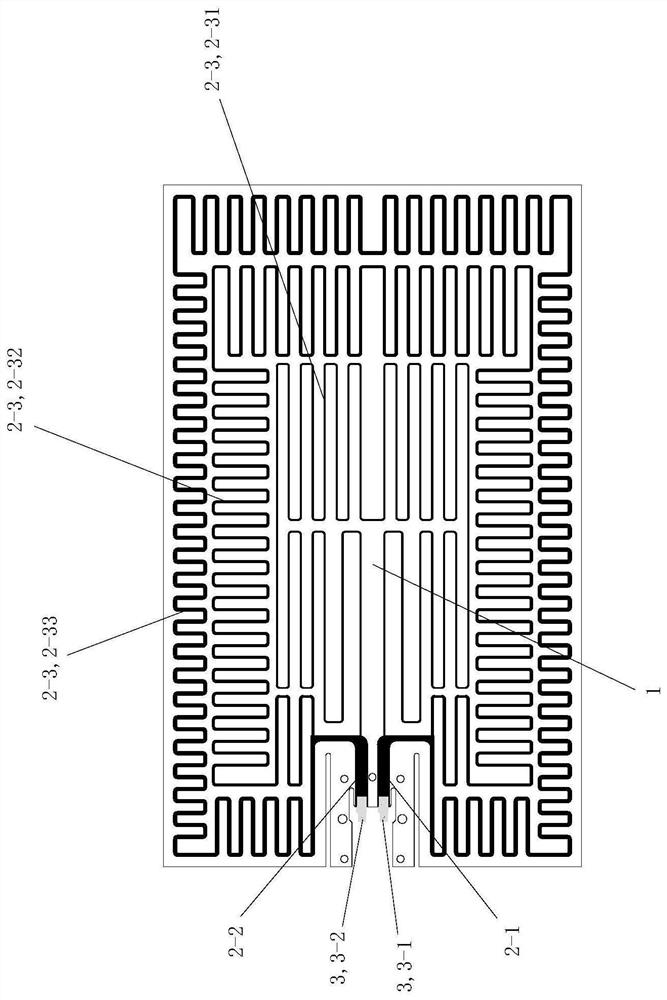

[0038] See image 3 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the heating part 2-3 includes an inner heating part 2-31, an inner ring heating part 2-32 and an outer ring heating part 2-33. The inner heating part 2-31, the inner ring heating part 2-32 and the outer ring heating part 2-33 are connected in parallel on the positive electrode connection part 2-1 and the negative electrode connection part 2-2. The inner heating part 2-31, the inner ring heating part 2-32 and the outer ring heating part 2-33 are arranged sequentially from the inside to the outside, the inner ring heating part 2-32 is arranged around the inner heating part 2-31, and the outer ring heating part 2 -33 is set around the inner ring heating part 2-32. The conductive cross-sectional area of the inner heating part 2-31, the inner ring heating part 2-32 and the outer ring heating part 2-33 is set to gradually increase. According to the formula P=I²R, the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com