Coke oven gas desulfurization process

A technology of coke oven gas and desulfurization process, which is applied in the fields of sulfur compounds, petroleum industry, combustible gas purification, etc. It can solve the problems of lye consumption, poor quality of sulfur paste, waste liquid generation, etc., and achieve high desulfurization efficiency and high product quality , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

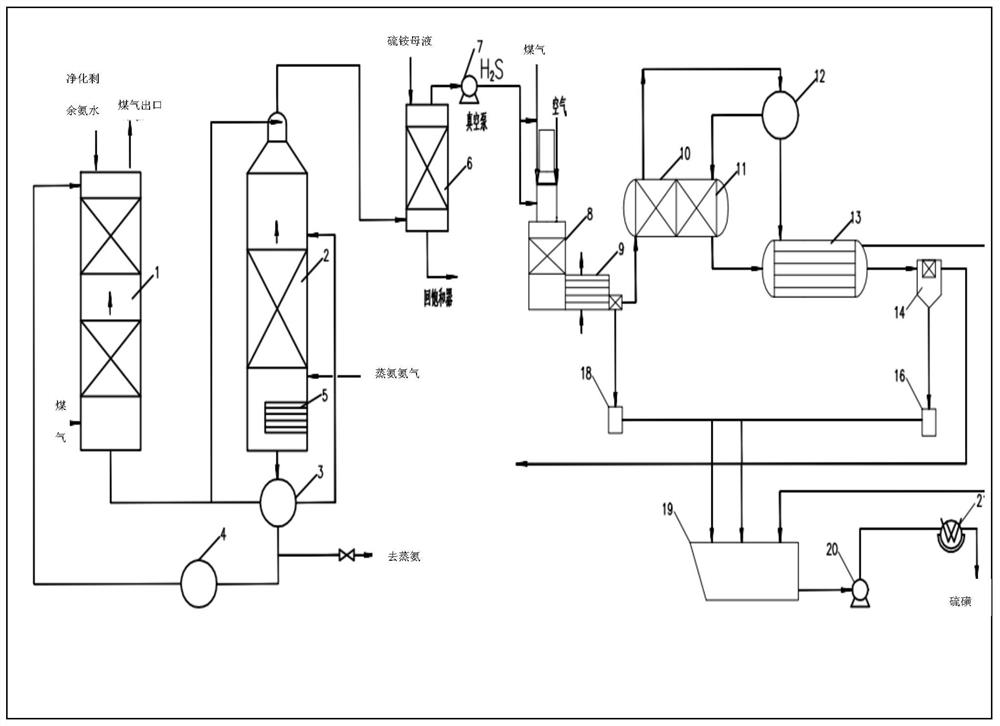

[0026] Embodiment 1 coke oven gas desulfurization process

[0027] (1) The coke oven gas from the electric tar collector enters the bottom of the desulfurization tower, and is in countercurrent contact with the desulfurization lean liquid and the remaining ammonia water cooled to 22°C from bottom to top, and then the gas passes through the alkali section, and the gas in the gas The acid gas is absorbed by the absorption liquid, and the H in the gas 2 The content of S and HCN is reduced to 200mg / L, and the gas comes out of the desulfurization tower, and the gas after removing the entrained liquid droplets is sent to the next process.

[0028] (2) The desulfurization rich liquid absorbing the acid gas in the coke oven gas at the bottom of the desulfurization tower is divided into two parts, 1 / 3 of which is sent to the upper part of the negative pressure deacidification tower for spraying, and the temperature at the top of the tower is controlled at 55-60 ° C; the remaining 2 / 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com