High-efficiency self-healing hydrogel enhanced by cellulose nanocrystals and preparation method thereof

A technology of nanocrystals and cellulose, applied in the field of highly efficient self-healing hydrogels reinforced by cellulose nanocrystals and its preparation, can solve the problems of unsatisfactory biocompatibility and poor self-healing performance of hydrogels, etc. Achieve the effect of improving biocompatibility, high swelling performance and high water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

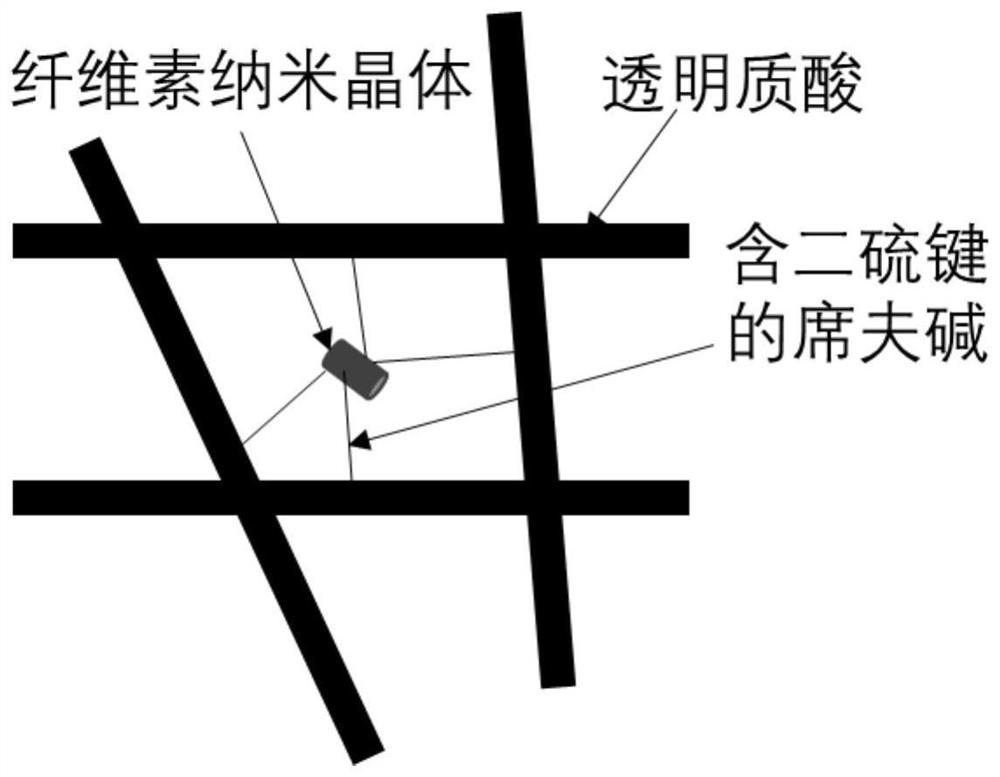

[0042] The present invention also provides a preparation method of a cellulose nanocrystal-enhanced high-efficiency self-healing hydrogel, comprising the following steps:

[0043] S1. Preparation of hydrazide-modified hyaluronic acid with disulfide bonds;

[0044] Dissolve a certain amount of hyaluronic acid in deionized water, prepare a solution with a mass-to-volume ratio of 1g:(20-200)ml, and then add carbodiimide (EDC), activation auxiliary (NHS) and 3,3 '-dithiodipropionic hydrazide; wherein, the molar ratio of hyaluronic acid and carbodiimide (EDC) is 1:(0.1~15), and the molar ratio of carbodiimide and activation auxiliary agent is 1:( 0.1~10), the molar ratio of hyaluronic acid and 3,3`-dithiodipropionyl hydrazide is 1:(1~15); then react at 25~50℃ for 1~24h, then dialyze with deionized water 1 to 3d, and then freeze-drying at -50 to -80° C. and 1 to 80 Pa to obtain hydrazide hyaluronic acid with a degree of substitution of 0.1 to 0.8.

[0045] S2. Prepare cellulose na...

Embodiment 1

[0053] A cellulose nanocrystal-enhanced high-efficiency self-healing hydrogel is prepared by the following steps:

[0054] S1. Preparation of hydrazide-modified hyaluronic acid with disulfide bonds

[0055] Dissolve a certain amount of hyaluronic acid in deionized water, prepare a solution with a mass-to-volume ratio of 1g:100ml, and then add carbodiimide (EDC), activation aid (NHS) and 3,3′-dithiol Dipropionyl hydrazide; wherein, the molar ratio of hyaluronic acid and carbodiimide (EDC) is 1:0.5, the molar ratio of carbodiimide and activation adjuvant is 1:0.5, and the molar ratio of hyaluronic acid and 3,3` -The molar ratio of dithiodipropionyl hydrazide is 1:5; then react at 25~50℃ for 1~24h, dialyze with deionized water for 1~3d, then at -50~-80℃, 1~80Pa Freeze-drying is carried out under conditions to obtain hydrazide hyaluronic acid with a degree of substitution of about 0.5.

[0056] S2. Prepare cellulose nanocrystal dispersion with aldehyde groups with a mass concent...

Embodiment 2-7 and comparative example 1

[0066] Compared with Example 1, the high-efficiency self-healing hydrogels reinforced by cellulose nanocrystals provided in Examples 2-7 and Comparative Example 1 are different in that the aldehyde-ylated cellulose nanocrystals prepared in step S2 have The lengths and diameters are shown in Table 1. Others are substantially the same as those in Embodiment 1, and are not repeated here.

[0067] Table 1 Preparation conditions and performance test results of Examples 1-7 and Comparative Example 1

[0068]

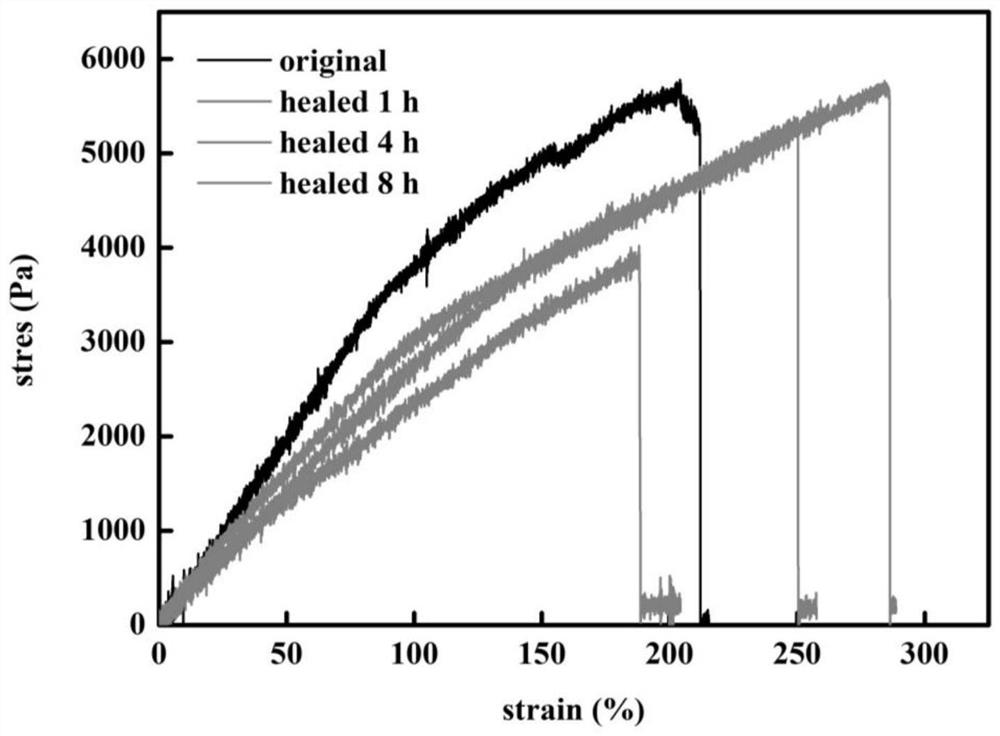

[0069] It can be seen from Table 1 that with the increase of the aspect ratio, the water absorption of the hydrogel first increases and then decreases, and the strength first increases and then decreases, but the self-healing efficiency gradually decreases; with the increase of the overall size The strength of the hydrogel tends to decrease gradually, which may be the result of the co-determination of the content of aldehyde groups on the crystal surface and the size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com