Lightweight thermal-insulation high-strength concrete and preparation method thereof

A high-strength concrete technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of complex production process of small ceramsite, increase the cost of concrete production, consume natural resources, etc., and achieve excellent bonding Performance and mechanical properties, enhance interface binding ability, solve the effect of not easy to disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

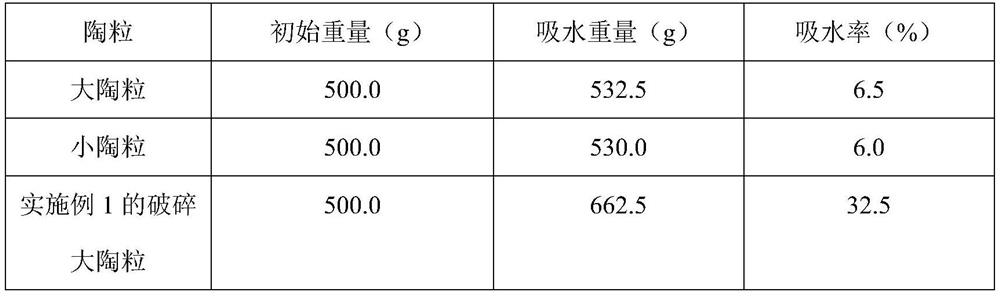

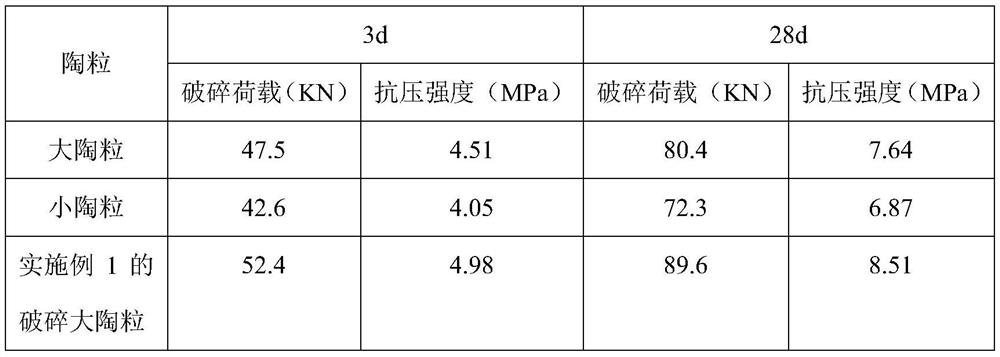

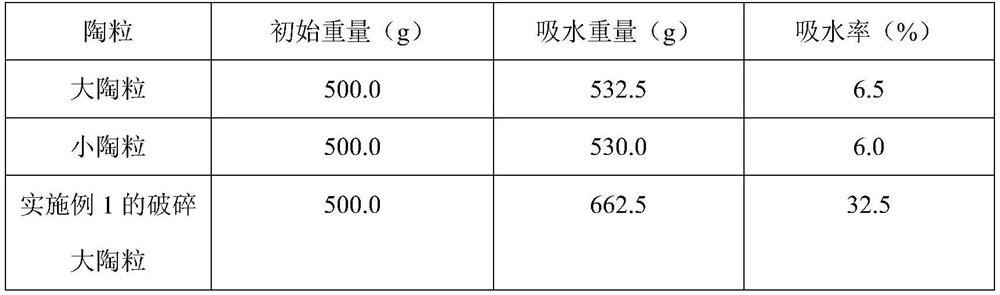

[0038] The light-weight thermal insulation high-strength concrete of the present invention comprises the following components: 270kg of cement, 130kg of ceramsite, 85kg of Class I fly ash, 360kg of cinder ash, 5.5kg of water reducer, foaming agent accounting for 5% of the cement mass, glass 0.7 kg of fiber, 0.7 kg of carbon fiber grafted with carbon nanotubes, and 110 kg of water. Among them, the cement is P.O42.5 ordinary Portland cement. The water-cement ratio is 0.45, the ceramsite is 5-10mm pre-wet crushed ceramsite, the type of water reducing agent is UC-III, the average length of glass fiber is about 20mm, and the average length of carbon fiber grafted with carbon nanotube is about 5mm . In the present invention, the large ceramsite refers to a particle size range of 20-25 mm, and the small ceramsite refers to a particle size range of 2.5-10 mm.

[0039] The preparation method of the above-mentioned lightweight thermal insulation high-strength concrete is:

[0040] (1...

Embodiment 2

[0050] Basically the same as Example 1, the difference is that 285kg of cement, 180kg of ceramsite, 100kg of Class I fly ash, 420kg of cinder ash, 6.3kg of water reducing agent, foaming agent accounted for 7% of the cement mass, 0.8kg of glass fiber, 0.9 kg of carbon fibers grafted with carbon nanotubes, and 160 kg of water. The water-cement ratio is 0.56, the ceramsite is pre-wet and broken ceramsite of about 5mm, the length of glass fiber is 30mm, and the length of carbon fiber grafted with carbon nanotubes is 3mm.

[0051] In the preparation method: in step (2), dry mix at low speed for about 20 seconds, so that each component material is evenly dispersed, and then add water, water reducing agent, foaming agent and mix wet at high speed for about 30 seconds;

[0052] In step (3), first use a high-frequency vibrating rod to vibrate for compaction for 25 s, and then use a vibrating table to vibrate for 25 s.

Embodiment 3

[0054] Basically the same as Example 1, the difference is that 300kg of cement, 220kg of ceramsite, 110kg of Class I fly ash, 480kg of cinder ash, 7kg of water reducer, foaming agent accounts for 9% of the cement mass, and 0.9kg of glass fiber. 1.2kg of carbon fiber grafted with carbon nanotubes, 110kg of water, water-cement ratio of 0.36, ceramsite is pre-wet broken ceramsite of about 10mm, length of glass fiber is 25mm, and carbon fiber length of grafted carbon nanotubes is 6mm.

[0055] In the preparation method: in step (2), dry mix at low speed for about 30 seconds, so that each component material is evenly dispersed, and then add water, water reducing agent, foaming agent and mix wet at high speed for about 40 seconds;

[0056] In step (3), first use a high-frequency vibrating rod to vibrate for compaction for 30 s, and then use a vibrating table to vibrate for 30 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com