Dental glaze composition, dental glaze forming method and denture prosthesis

A composition and restoration technology, applied in the field of dental restoration, can solve the problems of high sintering temperature, adverse health effects, restricted use, etc., and achieve the effects of improving quality, uniform glaze hanging, and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Tooth enamel composition, comprising the following components in mass percentage:

[0064] 60.4% SiO 2 , 10% B 2 o 3 , 0.5% ZrO 2, 9.0% Na 2 O, 7.0% K 2 O, 1.4% Li 2 O, 2.3% CaO, 9.3% Al 2 o 3 .

[0065] Among them, Na 2 O and K 2 The molar ratio of O is 2.0;

[0066] K 2 O and Li 2 The molar ratio of O is 1.5;

[0067] Na 2 O, K 2 O and Li 2 The three total mass percentages of O are 17.5%;

[0068] SiO 2 and Al 2 o 3 The molar ratio of is 11.0;

[0069] SiO 2 The molar ratio to CaO is 24.2.

[0070] The preparation process is:

[0071] 1) Ingredients: Take Na according to the above ratio 2 CO 3 、K 2 CO 3 , ZrO 2 , Li 2 CO 3 , CaCO 3 , SiO 2 、 Al 2 o 3 and B 2 o 3 to mix,

[0072] 2) Ball milling: Using the planetary ball milling process, put the mixture raw material obtained in step 1) into a polyurethane ball mill tank for ball milling. The corresponding parameters of ball milling are: rotating speed 340r / min, ball milling time 2h...

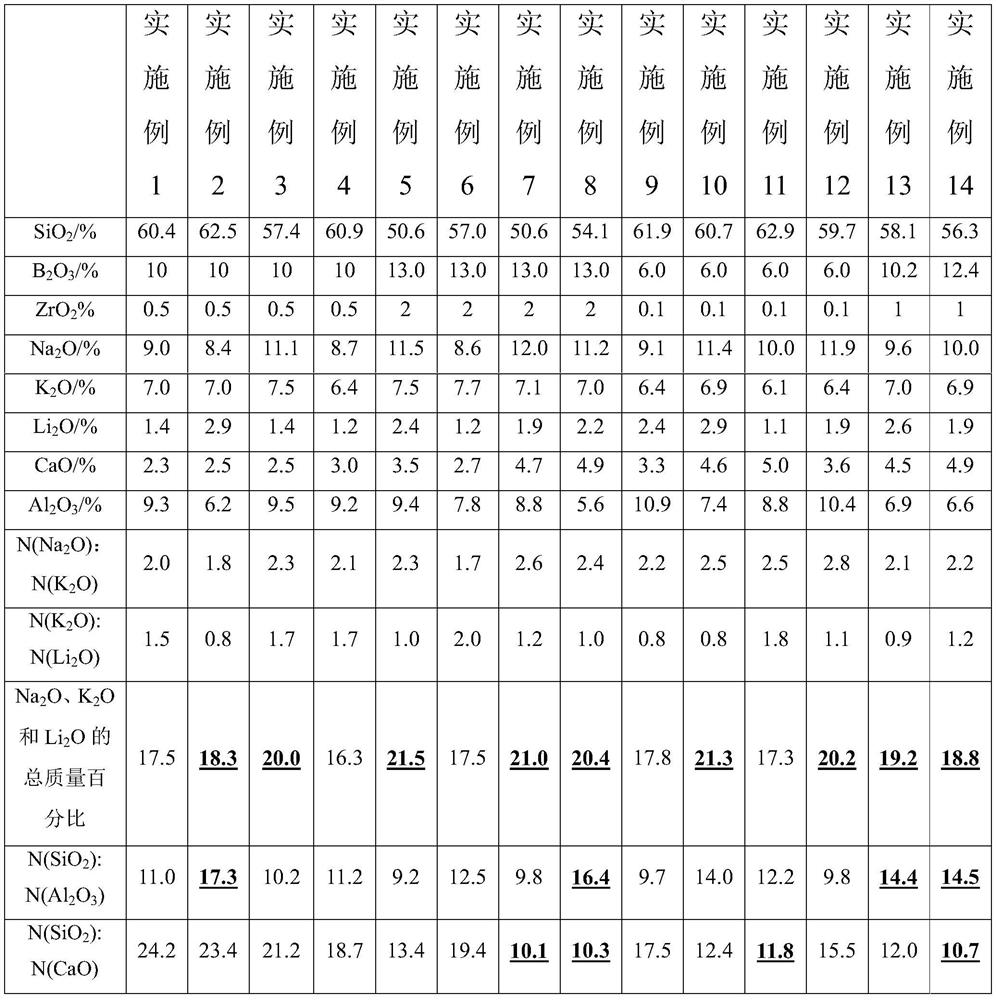

Embodiment 2~14

[0082] The difference of embodiment 2~14 and embodiment 1 is only that component content is different, as shown in table 1, each parameter in preparation process and preparation process is all identical with embodiment 1. N in Table 1 represents the molar weight, for example N(Na 2 O) stands for Na 2 The molar weight of O, the % in Table 1 represents the mass percent content.

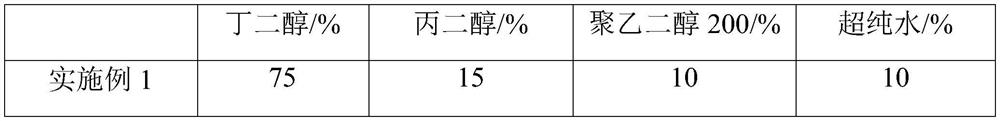

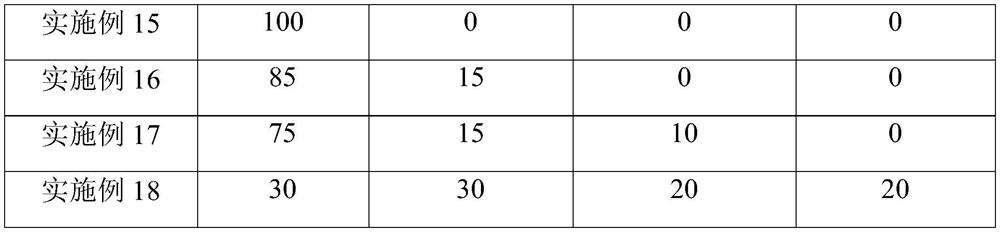

Embodiment 15~18

[0084] The difference between Examples 15-18 and Example 1 is only in the preparation of the solvent in step 7) of the preparation process, and the rest are the same as in Example 1. The solvent data are shown in Table 2, and the % in Table 2 represents the mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com