Lightweight connection method and device based on limited space driving motor and speed reducer

A drive motor and limited space technology, applied in the field of electric drive powertrain component connection method and device structure, can solve the problems of long axial structure size, lack of miniaturization and light weight of electric drive wheels, etc., and achieve weight reduction and shortening The effect of axial structure size and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

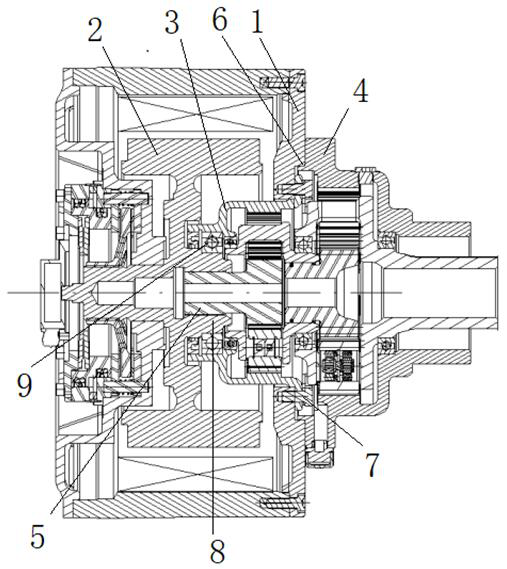

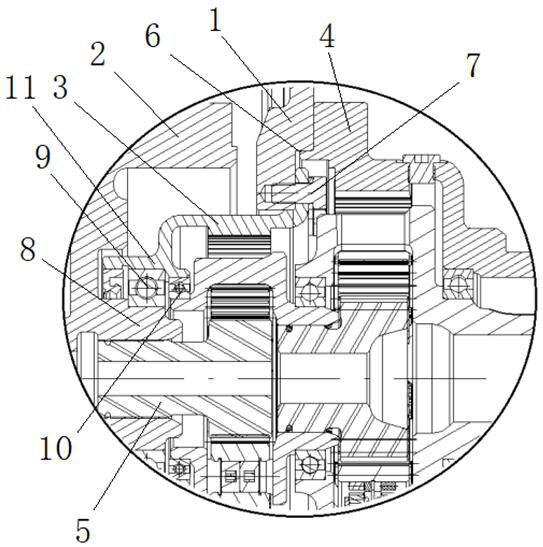

[0029] From attached figure 1 It can be seen that the present invention relates to a drive motor and reducer connection device based on limited space, including drive motor end cover 1, drive motor rotor 2, reducer left half shell 3, reducer right half shell 4 and reducer input The shaft 5 is characterized in that: the end cover 1 of the drive motor is provided with a notch 6 connected to the right half shell 4 of the reducer, and the right half shell 4 of the reducer is installed on the drive motor through fasteners (not shown in the figure). inside the seam 6 of the end cover; the left half shell 3 of the reducer is also installed in the seam 6 of the drive motor end cover, and is fixed together with the drive motor end cover 1 through fasteners 7; the left half shell 3 of the reducer Together with the right half shell 4 of the reducer and the end cover 1 of the drive motor, the whole shell of the reducer is formed, while the left half shell 3 of the reducer and the end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com