Full-automatic bearing seat assembling device and method

A technology for assembling equipment and bearing seats, which is applied in the direction of assembly machines, metal processing equipment, and devices for coating liquid on the surface, etc. It can solve the problems of low production efficiency, complicated process, and manual completion, so as to achieve high processing efficiency and high product quality. The effect of high pass rate and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

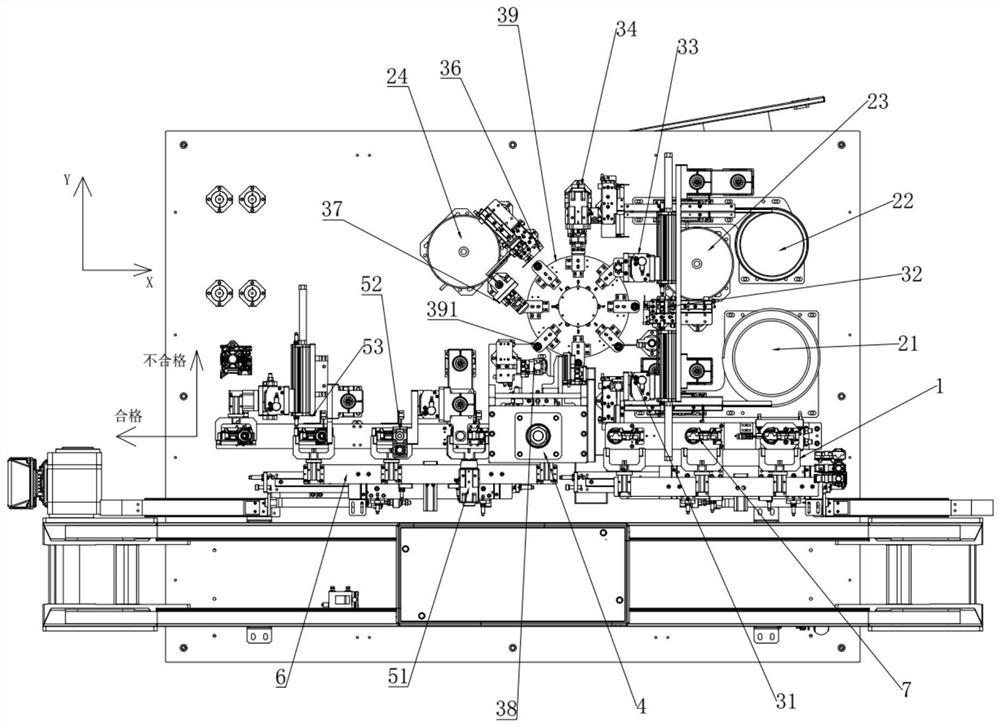

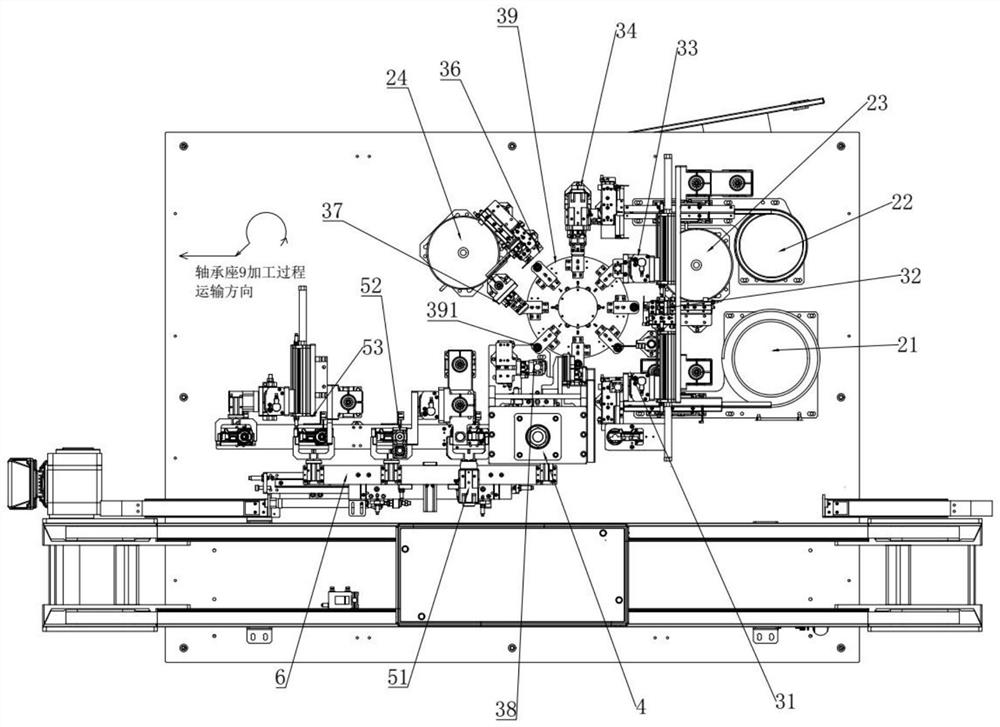

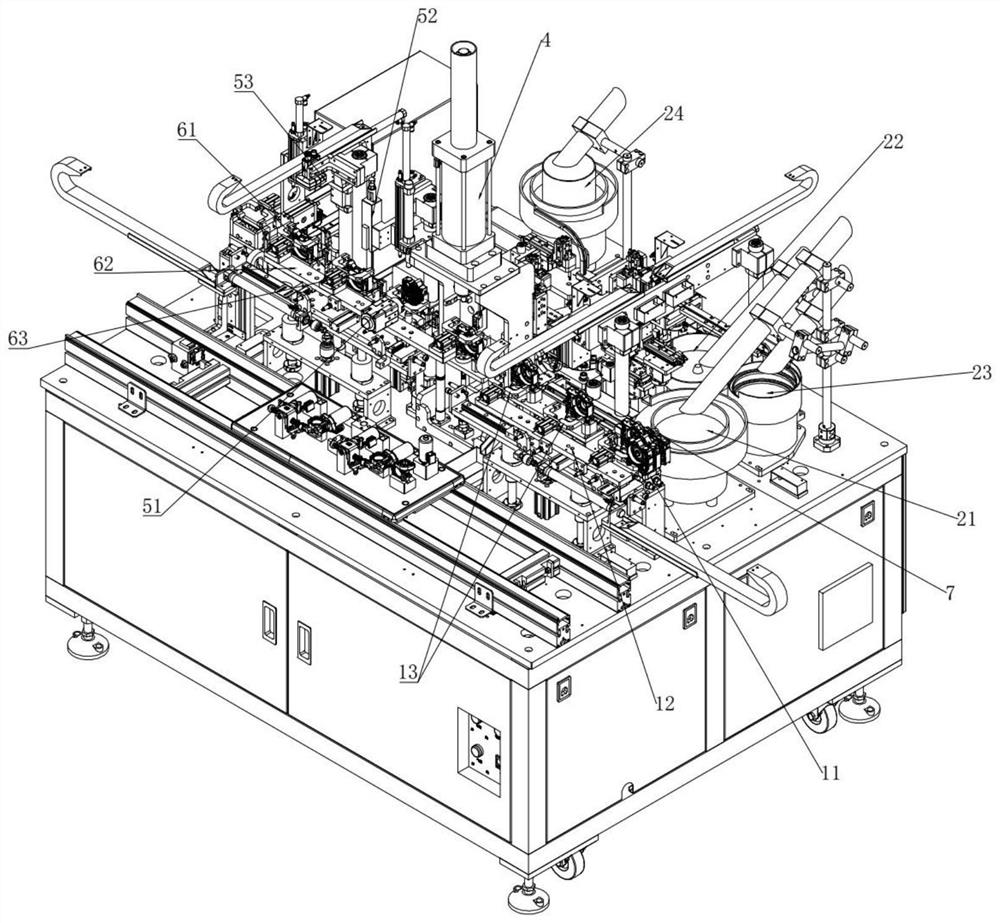

[0037] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0038] As described in the background technology, in the prior art, only a certain step in the automatic bearing assembly process can be semi-automatically produced, and most of the processing steps still need to be completed manually; the production efficiency is low; the fully automatic bearing seat assembly equipment of the present invention is used In the automatic tooth box and bearing seat assembly equipment, it is used to complete the automatic production process of the bearing seat. The automatic tooth box and bearing seat assembly equipment includes bearing seat processing, tooth box and bearing seat assembly, and oiling after assembly. Three major steps; in order to illustrate the solution of the present invention more clearly, the following will start from the working process of the automatic tooth box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com