Steel structure bridge truss welding tool and welding method

A technology for welding tooling and steel structures, applied in welding/welding/cutting items, welding equipment, welding equipment, etc., it can solve problems such as cracks and affect the safety of trusses, so as to reduce the generation of cracks, protect health and air environment, The effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

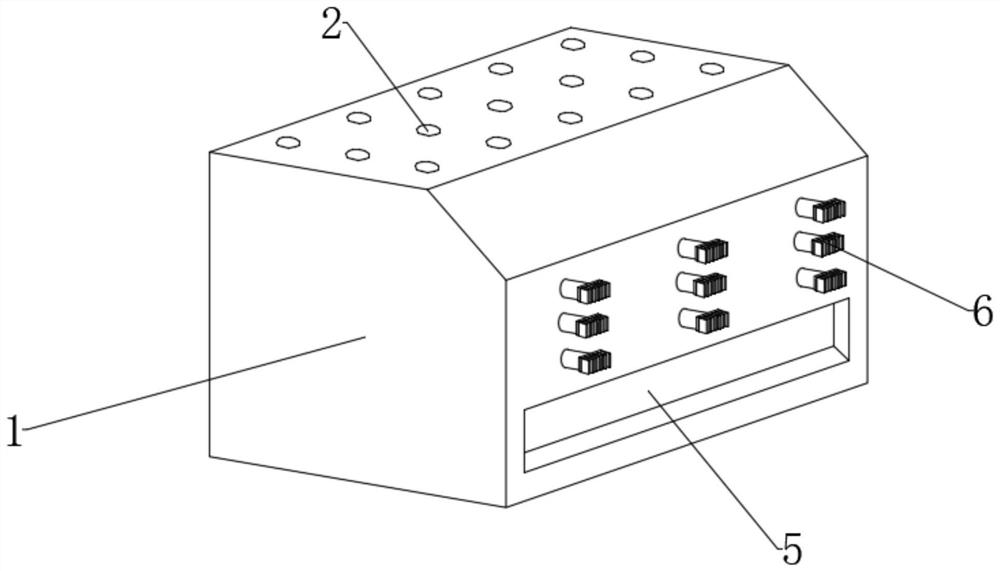

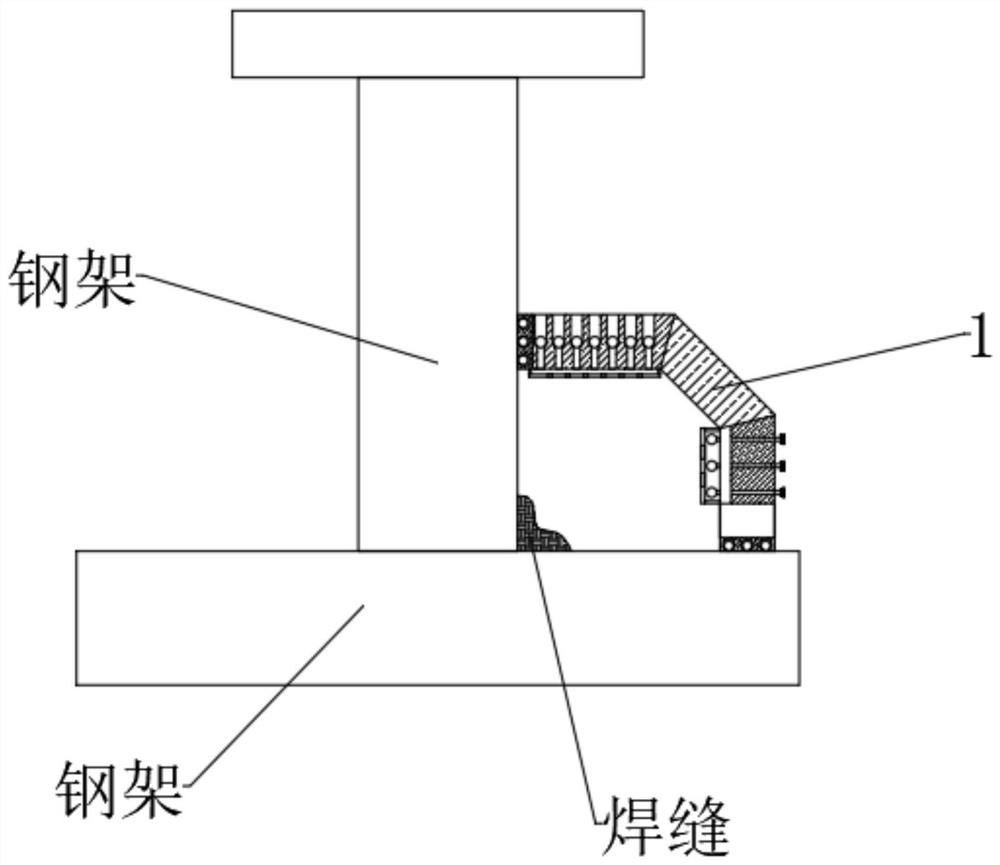

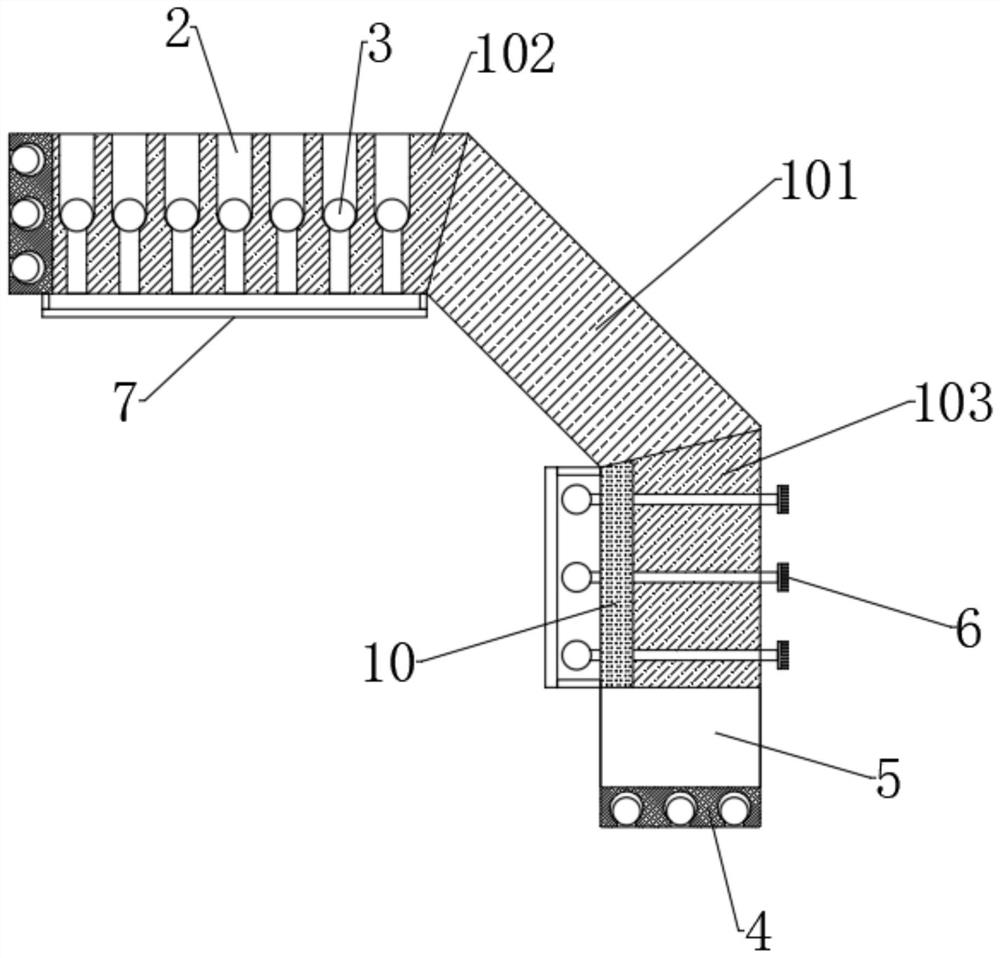

[0049] see Figure 1-10 , a steel structure bridge truss welding tool, including insulation and heat preservation cover 1, please refer to Figure 4 , the insulation insulation cover 1 is made up of a transparent observation body 101 in the middle and an upper insulation body 102 and a lower insulation body 103 on the upper and lower sides. The transparent observation body 101 is made of high temperature resistant glass material, and the upper insulation body 102 and the lower insulation body 103 are Made of non-thermally conductive material, the upper insulator 102 and the lower insulator 103 are made of the same material, please refer to Figure 5 , the side wall of the upper separator 102 is provided with a plurality of gas passages 2, and a purification ball 3 is placed in each gas passage 2, the gas passage 2 is composed of an upper passage and a lower passage, and the inner diameter of the upper passage is larger than that of the purification ball 3 Diameter, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com