Method for inhibiting spontaneous combustion of coal gangue pile and extracting heat of coal gangue pile for application

A technology for coal gangue and heat, applied in the field of coal gangue heat utilization, can solve the problems of wasting land resources, unable to live in or build workshops, etc., and achieve the effect of suppressing spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for suppressing spontaneous combustion of coal gangue piles and extracting its heat for application, comprising the following steps,

[0019] S100~Choose a site without groundwater seepage, excavate a 5-10m foundation pit (well drain the foundation pit), and the area of the foundation pit is determined according to the amount of coal gangue.

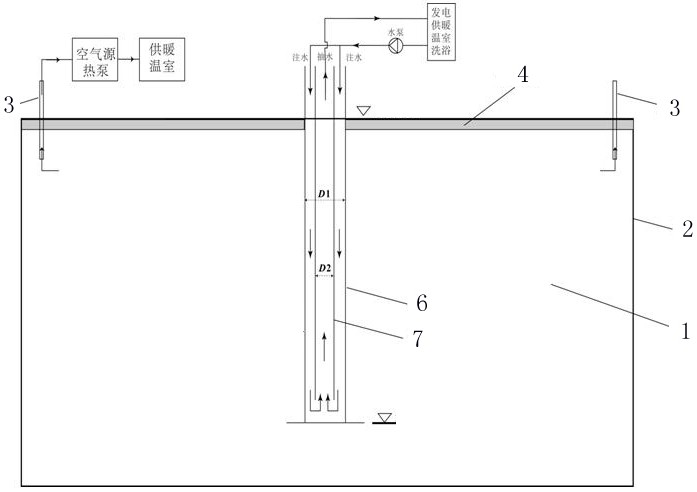

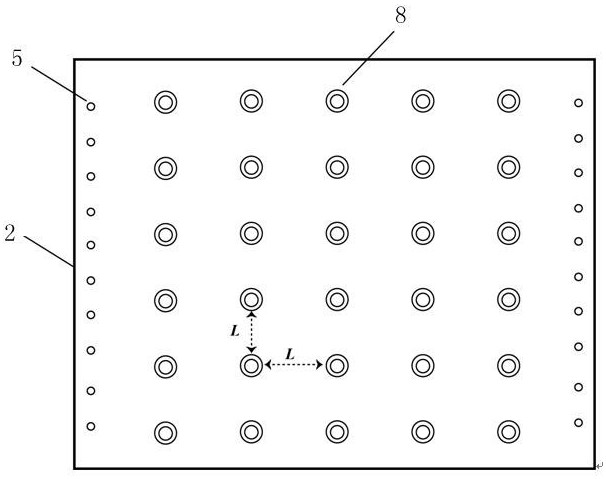

[0020] S200~according to figure 1 Lower into the inner and outer tubes of the coaxial casing, and then press figure 2 Multiple shallow coaxial casings (group holes) are pre-arranged into the foundation pit.

[0021] From S300~start to fill in coal gangue layer by layer. When backfilling, keep the coaxial casing upright without tilting, backfill to 0.5m below the surface, and then lay a covering layer on it to keep heat so that the heat of the gangue pile will not dissipate into the atmosphere.

[0022] S400~Two rows of exhaust holes are left at both ends of the covering layer to discharge the waste gas produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com