A method for forming connection lines on a glass substrate through the exposure principle of an exposure machine

A technology of glass substrate and exposure machine, which is applied in the direction of circuit substrate materials, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., can solve the problems of low production efficiency, looseness, high production cost, etc., to improve production efficiency, The effect of reducing frame width and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

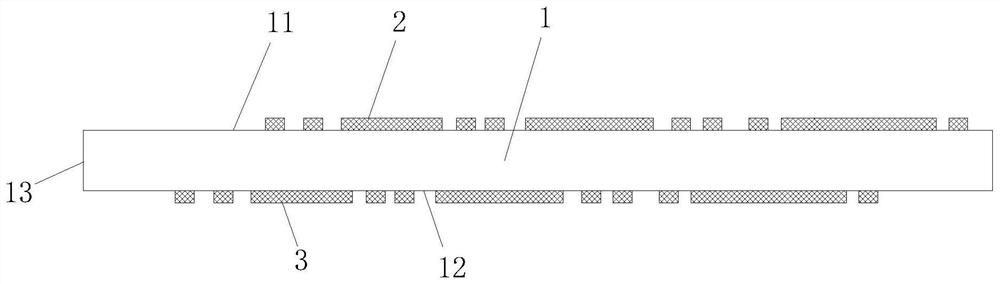

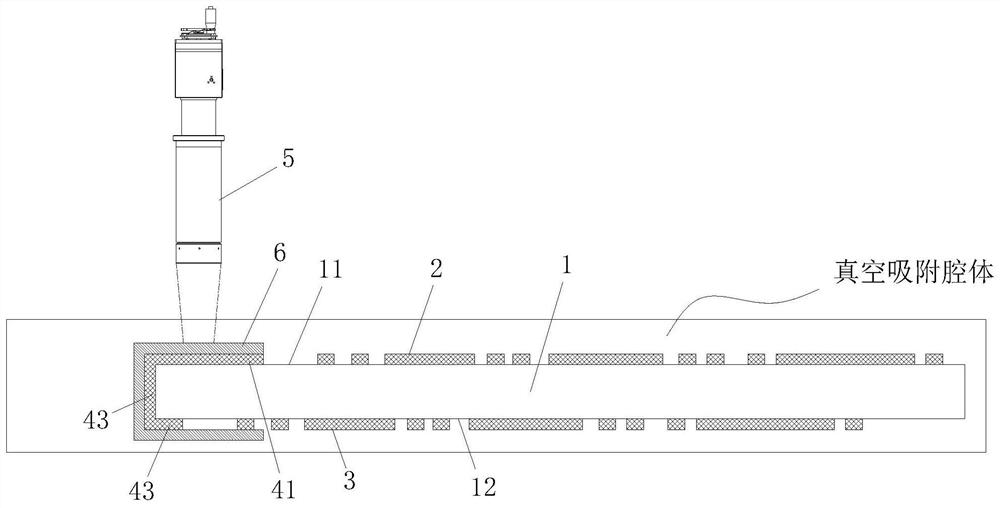

[0018] In this example, refer to figure 1 and figure 2 , the method of forming a connection line on a glass substrate through the exposure principle of an exposure machine, the glass substrate 1 includes an A surface 11, a B surface 12 and a side surface 13, and the thickness of the glass substrate 1 is 0.1-1mm; on the A surface 11 has A-side circuit 2, B-side 12 has B-side circuit 2, and a photolithography head 5 is respectively formed along A-side 11, B-side 12 and side 13 to form a connection circuit, and A-side circuit 2 is formed through the connection circuit. To achieve electrical interconnection with the line 3 on the B side, the implementation process is carried out according to the following steps,

[0019] S1. Clean the surface of the glass substrate 1, coat a layer of conductive material on the surface of the glass substrate 1, and then use a mask with a line and cooperate with UV ink to go through the exposure-development-etching process to make the A surface 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com