Nitrogen-doped carbon nanosheet/MXene composite nanomaterial as well as preparation method and application thereof

A technology of composite nanomaterials and carbon nanosheets, applied in the field of electrochemical energy, can solve the problems that the electrochemical performance cannot be fully utilized, and achieve the effects of improving cycle stability, promoting pseudocapacitive characteristics, and overcoming stacking and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

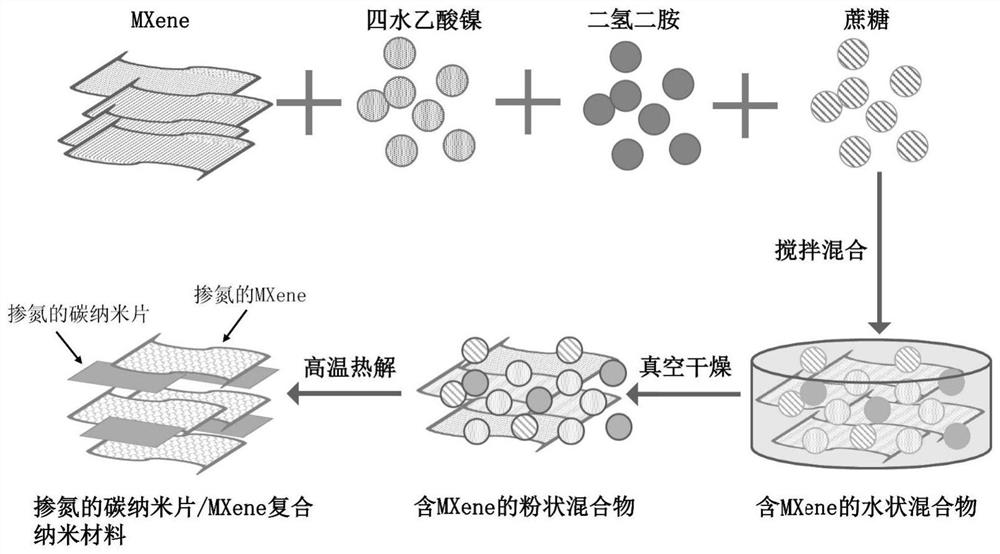

[0061] S1, a flow chart for the preparation of nitrogen-doped carbon nanosheets / MXene composite nanomaterials figure 1 Shown, concrete preparation method comprises the following steps:

[0062] (1) According to the weight fraction, 4 parts of Ti 3 C 2 Mix well with 1 part of nickel acetate tetrahydrate, 20 parts of dihydrodiamine and 2 parts of sucrose, add a little (10 mL) deionized water to dissolve the mixture completely, stir well, and dry in vacuum at 60 °C for 48 hours to obtain MXene-containing powder shape mixture;

[0063] (2) Under the protection of argon gas flow, the mixture was preheated to 600°C, kept for 2 hours, then heated to 800°C, kept for 2 hours, cooled to room temperature, taken out, and carefully ground to obtain nitrogen-doped carbon nanosheets / MXene composite nano Material;

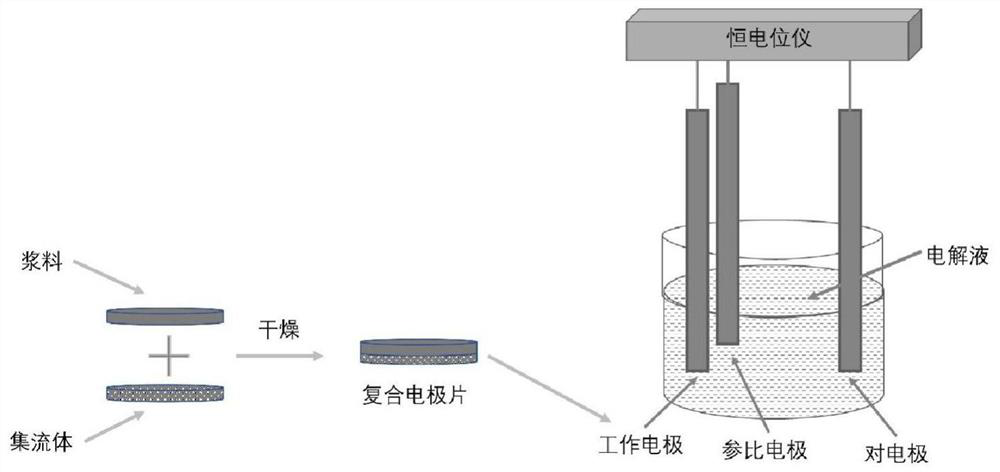

[0064] S2, a composite electrode sheet, and the preparation flow chart of using the composite electrode sheet to prepare a three-electrode system assembly is as follows figu...

Embodiment 2

[0072] S1, a preparation method of nitrogen-doped carbon nanosheet / MXene composite nanomaterial:

[0073] (1) According to the weight fraction, 3 parts of Ti 3 C 2 Mix well with 1 part of nickel acetate tetrahydrate, 20 parts of dihydrodiamine and 1 part of sucrose, add a little (10 mL) deionized water to dissolve the mixture completely, stir well, and dry in vacuum at 60 °C for 48 hours to obtain MXene-containing powder shape mixture;

[0074] Under the protection of argon gas flow, the mixture was preheated to 600°C, kept for 3 hours, then heated to 700°C, kept for 2 hours, cooled to room temperature, taken out, and carefully ground to obtain nitrogen-doped carbon nanosheets / MXene composite nanomaterials ;

[0075] S2, a preparation method of a composite electrode sheet comprises the following steps:

[0076] (3) Mix nitrogen-doped carbon nanosheets / MXene composite nanomaterials, conductive agent and polyvinylidene fluoride in a ratio of 8:1:1 by weight, then add N-methy...

Embodiment 3

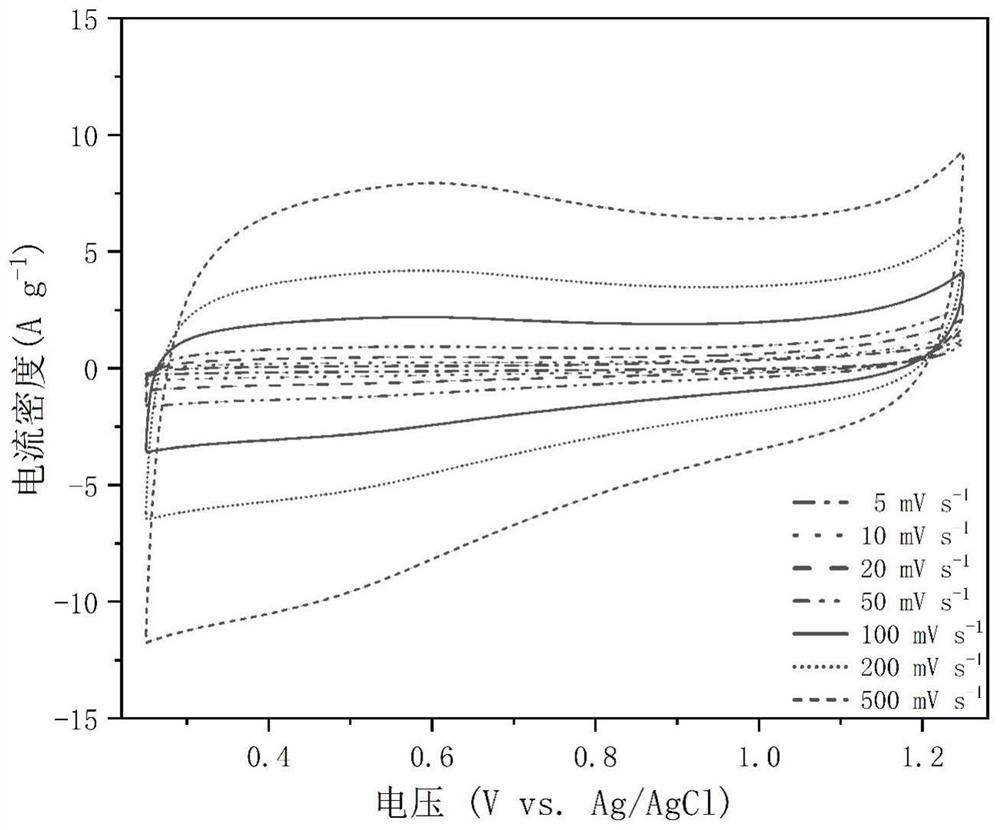

[0083] The difference with Example 1 is that the weight fraction of dihydrodiamine described in step (1) is 40 parts;

[0084] Composite electrode sheets and supercapacitors are prepared in the same manner as in Example 1, and the electrochemical performance of the supercapacitor is tested by a battery testing instrument: the specific capacitance is about 334F / g at a scan rate of 5mV / s, and the scan rate is expanded to 100 After double (500mv / s), the specific capacitance is about 124F / g, the electrochemical cycle charge and discharge performance is stable, and the internal resistance is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com