Oil-gas-solid multi-fuel solid heat carrier furnace

A solid heat carrier and multi-fuel technology, which is applied in the direction of gas fuel burner, burning fuel in molten state, non-flammable liquid/gas transportation, etc. Burner does not work and other problems, to achieve the effect of small excess air coefficient, ensure smooth combustion and low NOx content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

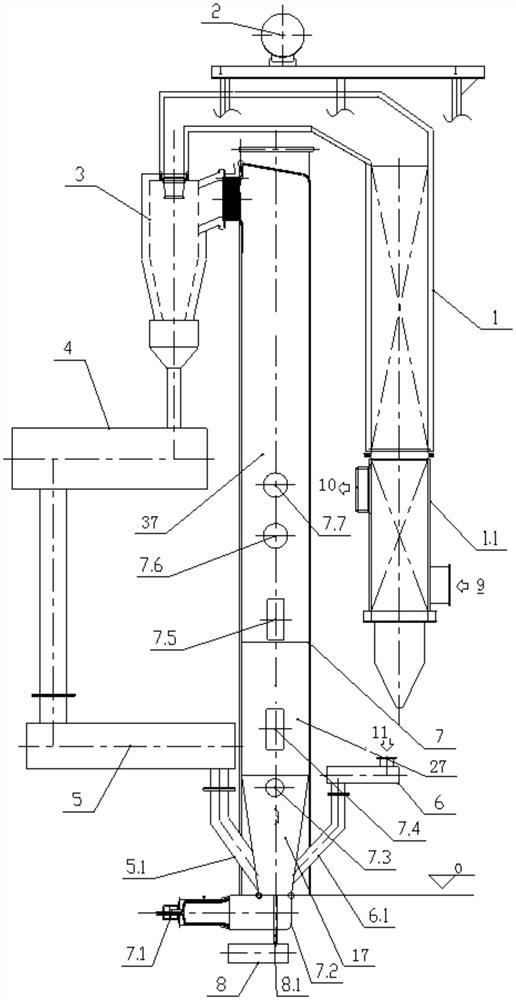

[0035] An oil-gas-solid multi-fuel solid heat carrier furnace: 1 waste heat boiler, 1.1 air preheater, 2 steam drum, 3 cyclone separator, 4 reactor, 5 feeder, 5.1 feeder pipe, 6 feeder, 6.1 Feed pipe, 7 solid heat carrier furnace, 17 dense-phase area, 27 thin-dense transition area, 37 dilute-phase area, 7.1 bottom burner, 7.2 primary air chamber, 7.3 lower secondary air duct, 7.4 side wall burner 1 , 7.5 side wall burner 2, 7.6 side wall burner 3, 7.7 side wall burner 4, 8 drum slag cooling machine, 8.1 slag discharge pipe. See figure 1 shown.

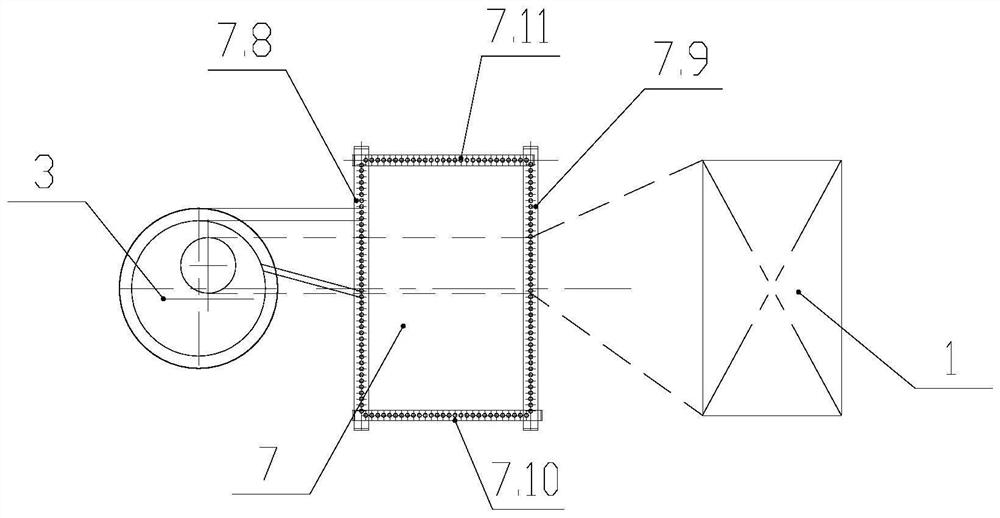

[0036] The solid heat carrier furnace 7 has a rectangular cross-section structure, including a front wall 7.8, a rear wall 7.9, a side wall A7.10, and a side wall B7.11, see figure 2 .

[0037] The solid heat carrier furnace 7 is a water-cooled hearth, and a layer of wear-resistant castable is laid on the outer surface of the water-cooled wall, and the thickness of the castable is less than 50 mm. Insulation castable structure can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com