Prefabricated kitchen and toilet composite slab splicing structure and splicing method

A technology of laminated boards, kitchen and bathroom, applied in the direction of building structure, construction, etc., can solve the problems of difficult construction of post-casting belt after height difference, easy cracking of dense joints, etc., to solve water seepage and cracking, avoid cracks on the board surface, The effect of strengthening connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

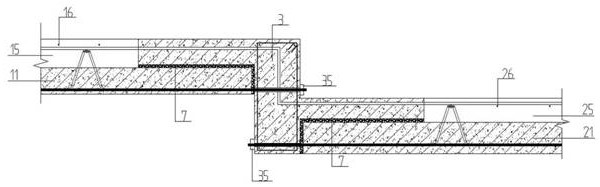

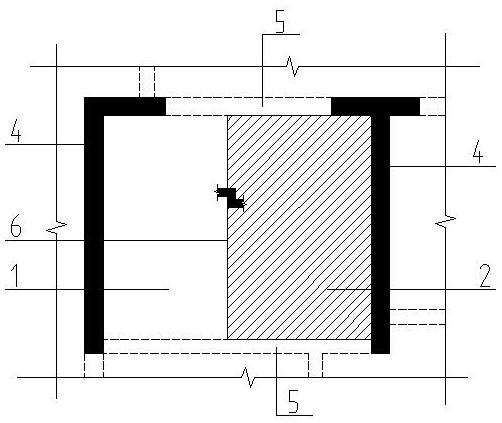

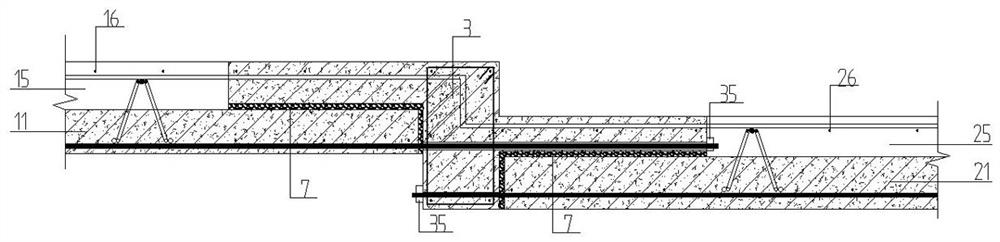

[0033] Such as figure 1 As shown, a prefabricated kitchen and bathroom laminated board splicing structure is divided into a normal area and a lowered board area by the lowered board boundary line 6 under the four-sided support conditions of the wall support 4 and the beam support 5, wherein the height of the lowered board is not greater than 50mm , set the receiving body 3 between the normal area and the lower plate area to strengthen the connection.

[0034] Such as image 3 As shown: the receiving body 3 includes the receiving body longitudinal reinforcement 31, the Z-shaped plate gluten 32 and the receiving body stirrup 33, the receiving body stirrup 33 is located in the middle of the receiving body 3, and the two ends of the Z-shaped plate gluten 32 extend to the bottom of the receiving body 3 outside. Among them, the diameter of the reinforcement bar 32 of the Z-shaped plate and the stirrup bar of the receiving body 33 shall not be less than 8 mm, and the horizontal arr...

Embodiment 2

[0040] Such as figure 1 As shown, a prefabricated kitchen and bathroom laminated board splicing structure is divided into a normal area and a lowered board area by the lowered board boundary line 6 under the four-sided support conditions of the wall support 4 and the beam support 5, wherein the height of the lowered board is not less than 100mm , not more than 300mm, set the receiving body 3 between the normal area and the lower plate area to strengthen the connection.

[0041] Such as Figure 6 and Figure 7 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that the positions of the reserved holes 34 for bottom ribs on the receiving body 3 are different. The reserved hole for the bottom reinforcement of the middle laminated slab is located in the middle of the Z-shaped receiving body 3 (that is, the section where the stirrup of the receiving body is located), below the overlapping section of the receiving body 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com