Ultra-high performance concrete stone-like brick

An ultra-high performance, concrete technology, applied in the field of building materials, can solve the problems of easy breakage of concrete bricks and unsightly appearance, achieve good decorative effect, improve flexural and tensile strength, and improve load-bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

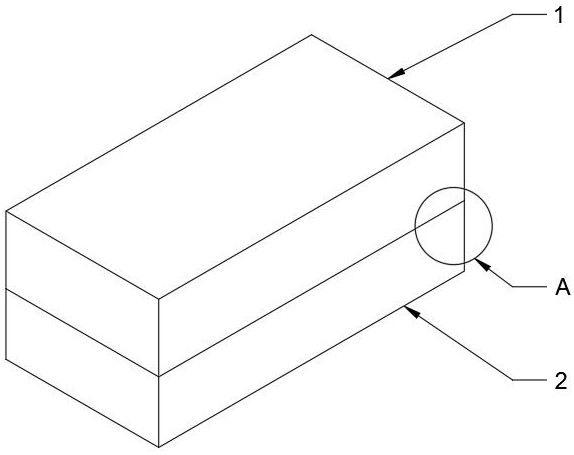

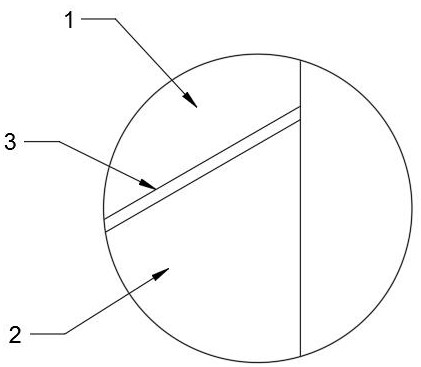

[0024] An ultra-high-performance concrete imitation stone brick, comprising a surface layer 1 and a bottom layer 2, an interlayer 3 is arranged between the surface layer 1 and the bottom layer 2, the interlayer 3 is a mesh cloth made of polypropylene, and the mesh density of the interlayer 3 is 200 mesh, in parts by weight, the raw materials of surface layer 1 include: 750 parts of PW cement, 120 parts of heavy calcium powder, 120 parts of white silica fume, 10 parts of titanium dioxide, 780 parts of 20-40 mesh quartz sand, 40-70 mesh quartz sand 320 parts of sand, 150 parts of 325-mesh quartz sand, 10 parts of plastic steel fiber, and 100 parts of water; the raw materials of bottom layer 2 include: 700 parts of PO cement, 110 parts of secondary fly ash, 180 parts of gray silica fume, 20-40 mesh quartz 780 parts of sand, 320 parts of 40-70 mesh quartz sand, 150 parts of 325 mesh quartz sand, 90 parts of steel fiber, 120 parts of water, 40 parts of steel fiber with a length of 6...

Embodiment 2

[0034] An ultra-high-performance concrete imitation stone brick, comprising a surface layer 1 and a bottom layer 2, an interlayer 3 is arranged between the surface layer 1 and the bottom layer 2, the interlayer 3 is a mesh cloth made of glass fiber, and the mesh density is 100 meshes. In parts by weight, the raw materials of surface layer 1 include: 800 parts of PW cement, 130 parts of heavy calcium powder, 130 parts of white silica fume, 30 parts of titanium dioxide, 725 parts of 20-40 mesh quartz sand, 320 parts of 40-70 mesh quartz sand , 135 parts of 325-mesh quartz sand, 15 parts of plastic steel fiber, and 120 parts of water; the raw materials of the bottom layer 2 include: 725 parts of PO cement, 120 parts of first-grade fly ash, 200 parts of gray silica fume, and 780 parts of 20-40 mesh quartz sand , 305 parts of 40-70 mesh quartz sand, 145 parts of 325 mesh quartz sand, 100 parts of steel fiber, 140 parts of water, steel fibers with a length of 6 mm and 10 mm each acco...

Embodiment 3

[0038] An ultra-high-performance concrete imitation stone brick, comprising a surface layer 1 and a bottom layer 2, an interlayer 3 is arranged between the surface layer 1 and the bottom layer 2, the interlayer 3 is a mesh cloth made of glass fiber, and the mesh density is 20 meshes. In parts by weight, the raw materials of surface layer 1 include: 850 parts of PW cement, 140 parts of heavy calcium powder, 140 parts of white silica fume, 40 parts of titanium dioxide, 700 parts of 20-40 mesh quartz sand, 300 parts of 40-70 mesh quartz sand , 100 parts of 325-mesh quartz sand, 20 parts of steel fiber with a length of 10 mm, and 140 parts of water; the raw materials of the bottom layer 2 include: 750 parts of PO cement, 125 parts of primary fly ash, 210 parts of gray silica fume, 20-40 mesh quartz 720 parts of sand, 280 parts of 40-70 mesh quartz sand, 150 parts of 325 mesh quartz sand, 110 parts of steel fiber, 140 parts of water, 60 parts of steel fiber with a length of 6mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com